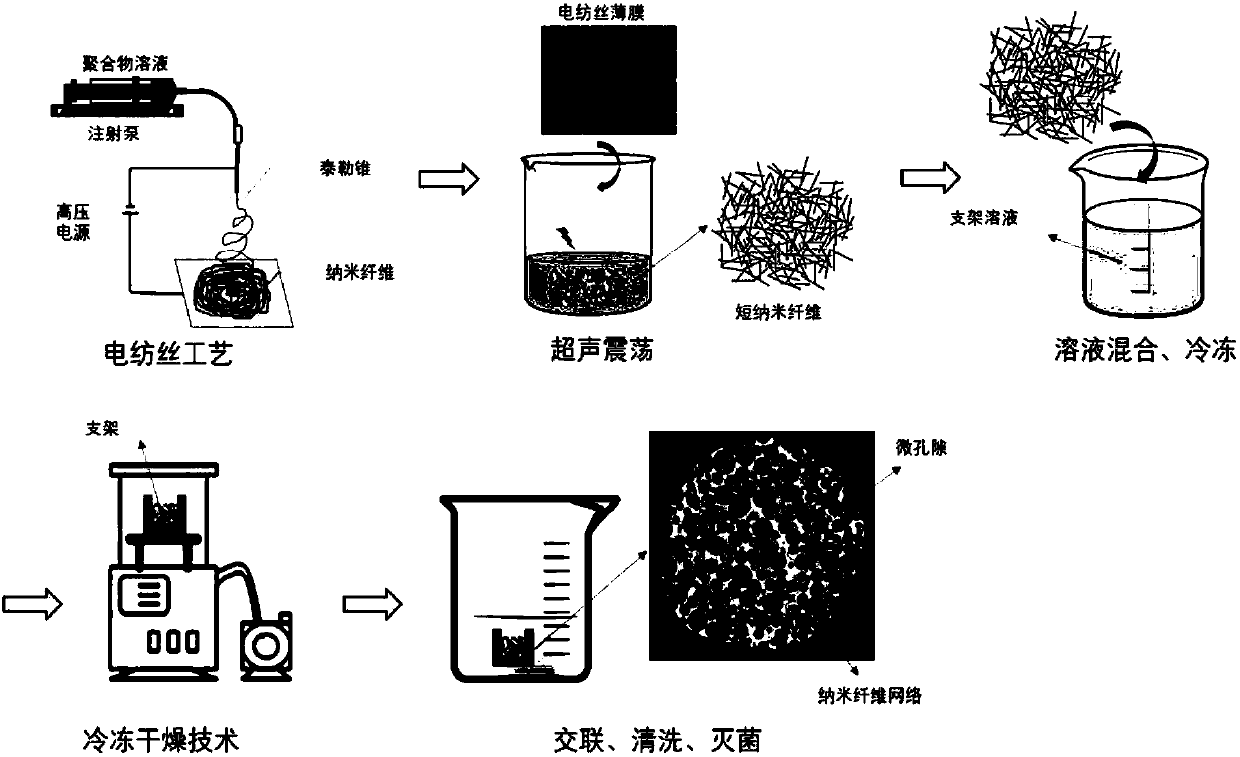

Bionic tissue engineering scaffold containing micropore and nanofiber composite structure and preparation method thereof

A technology of tissue engineering scaffolds and nanofibers, applied in tissue regeneration, fiber treatment, non-woven fabrics, etc., can solve the problems of small micropores of scaffolds, difficult cells, poor mechanical properties, etc., and achieve the effect of promoting cell adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1: Preparation of a biomimetic tissue engineering scaffold with micropores and nanofiber network

[0050] Dissolve gelatin (Gelatin, 15k~25kDa) in PBS buffer solution to prepare a gelatin solution with a concentration of 0.01g / mL; dissolve sodium alginate in PBS buffer solution to prepare a concentration of 0.01g / mL alginic acid Sodium solution; the above two solutions are prepared into a uniform, bubble-free, and precipitation-free mixed solution, namely a gelatin-sodium alginate mixed solution, the mass ratio of gelatin to sodium alginate is 1:1, and the concentration of gelatin is 0.005g / mL, the concentration of sodium alginate is 0.005g / mL.

[0051] The collagen type I (Collagen, sigma) was dissolved in 1% acetic acid solution to prepare a collagen solution with a concentration of 0.08g / mL, crosslinked with 0.5wt% genipin solution, and then dissolved in hexafluoroiso In propanol (HFIP), an electrospinning equipment is used to prepare collagen fibers (diameter o...

Embodiment 2

[0054] Example 2: Preparation of a biomimetic tissue engineering scaffold with micropores and nanofiber network

[0055] Rat tail type I collagen (SIGMA company, product number C7661) was dissolved in 1.0wt% acetic acid solution to prepare a collagen solution with a mass fraction of 0.01g / mL; chitosan was dissolved in 1.0wt% acetic acid solution to prepare Prepare a chitosan solution with a mass fraction of 0.01g / mL; prepare the above two solutions into a homogeneous, bubble-free, and precipitate-free mixed solution, that is, a collagen-chitosan solution. The mass ratio of collagen to chitosan is 1 :1. The concentration of collagen is 0.005g / mL, and the concentration of chitosan is 0.005g / mL.

[0056] Dissolve polycaprolactone (PCL) in hexafluoroisopropanol (HFIP) to prepare a 0.1g / mL PCL solution, and use electrospinning equipment to prepare PCL fibers (with a diameter of 2.0±0.5μm), where the syringe is extruded The speed is 0.8ml / h, the voltage is 20kV, and the collection devic...

Embodiment 3

[0059] Example 3: Preparation of a biomimetic tissue engineering scaffold with micropores and nanofiber network

[0060] Dissolve silk fiber in 1.0wt% acetic acid solution to prepare a silk fibroin solution with a mass fraction of 0.005g / mL; dissolve chitosan in 1.0wt% acetic acid solution to prepare a mass fraction of 0.015g / mL chitosan solution; prepare the above two solutions into a uniform, bubble-free, and precipitation-free mixed solution, that is, a silk fibroin-chitosan solution. The mass ratio of silk fibroin to chitosan is 3 :1, the concentration of silk fibroin is 0.005g / mL, and the concentration of chitosan is 0.015g / mL.

[0061] Poly D, L-lactide (PDLLA) was dissolved in chloroform to prepare 0.15g / mL PDLLA solution, and PDLLA fiber (diameter 5.0±2.5μm) was prepared using electrospinning equipment, where the extrusion speed of the syringe It is 1.6ml / h, the voltage is 20kV, and the collection device is about 15cm away from the needle tip. The collected PDLLA fibers w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com