Heavy metal contaminated soil remediation method and remediation agent

A soil remediation agent and a technology for polluted soil, which is applied in the field of heavy metal-contaminated soil remediation methods and remediation agents, and can solve problems such as poor repair methods and inconvenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for remediating heavy metal contaminated soil, comprising the steps of:

[0032] (1) Prepare soil remediation agent:

[0033] a. After cleaning the straw, put it into the steam explosion tank for steam explosion treatment, and take it out for later use;

[0034] b. Immerse the stalks treated in operation a into the composite solution A, and filter out after stirring continuously for 45 minutes, and then dry them for later use;

[0035] c. Mix the montmorillonite and the stalks treated in operation b together, then add potassium hydroxide solution, continue grinding for 3 hours, filter out, and finally obtain the mixed powder I after roasting treatment;

[0036] d. Rinse the mixed powder I obtained in step c with deionized water, and obtain the mixed powder II after washing until neutral;

[0037] e. Put the mixed powder II, gelatin, chitosan, starch, and water obtained in step b into a mixing tank, take out after stirring for 5 hours, and then pulverize throu...

Embodiment 2

[0046] A method for remediating heavy metal contaminated soil, comprising the steps of:

[0047] (1) Prepare soil remediation agent:

[0048] a. After cleaning the straw, put it into the steam explosion tank for steam explosion treatment, and take it out for later use;

[0049] b. Immerse the stalks treated in operation a into the composite liquid A, and filter out after stirring continuously for 50 minutes, and then dry them for later use;

[0050] c. Mix the montmorillonite and the straw treated in operation b together, then add potassium hydroxide solution, continue grinding for 3.6 hours, filter out, and finally obtain the mixed powder I after roasting treatment;

[0051] d. Rinse the mixed powder I obtained in step c with deionized water, and obtain the mixed powder II after washing until neutral;

[0052] e. Put the mixed powder II, gelatin, chitosan, starch and water obtained in step b into the mixing tank, take it out after stirring for 6 hours, and then pulverize th...

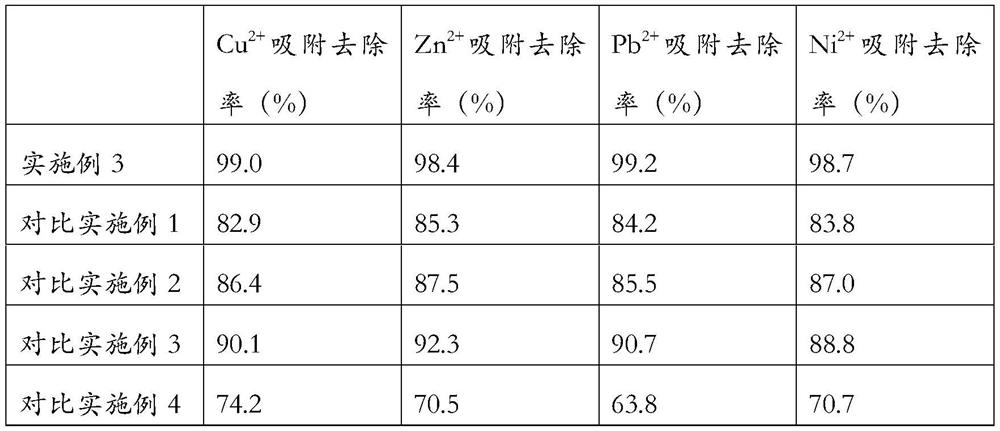

Embodiment 3

[0061] A method for remediating heavy metal contaminated soil, comprising the steps of:

[0062] (1) Prepare soil remediation agent:

[0063] a. After cleaning the straw, put it into the steam explosion tank for steam explosion treatment, and take it out for later use;

[0064] b. Immerse the stalks treated in operation a into the compound liquid A, and filter out after stirring continuously for 55 minutes, and then dry them for later use;

[0065] c. Mix the montmorillonite and the stalks treated in operation b together, then add potassium hydroxide solution, keep grinding for 4 hours, filter out, and finally get the mixed powder I after roasting for later use;

[0066] d. Rinse the mixed powder I obtained in step c with deionized water, and obtain the mixed powder II after washing until neutral;

[0067] e. Put the mixed powder II, gelatin, chitosan, starch and water obtained in step b into the mixing tank, take it out after stirring for 7 hours, and then pulverize through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com