Preparation method of collar button type artificial cornea

A technology for artificial corneas and workpieces, which is applied in the field of collar button artificial corneas. It can solve the problems that the joint between the back plate and the mirror column cannot be completely matched, it is difficult to adapt to batch production, and the visual clarity is reduced, so as to reduce pollution and accessories. Risk of non-uniformity, improvement of production efficiency and yield of finished products, and effect of improvement of precision and clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

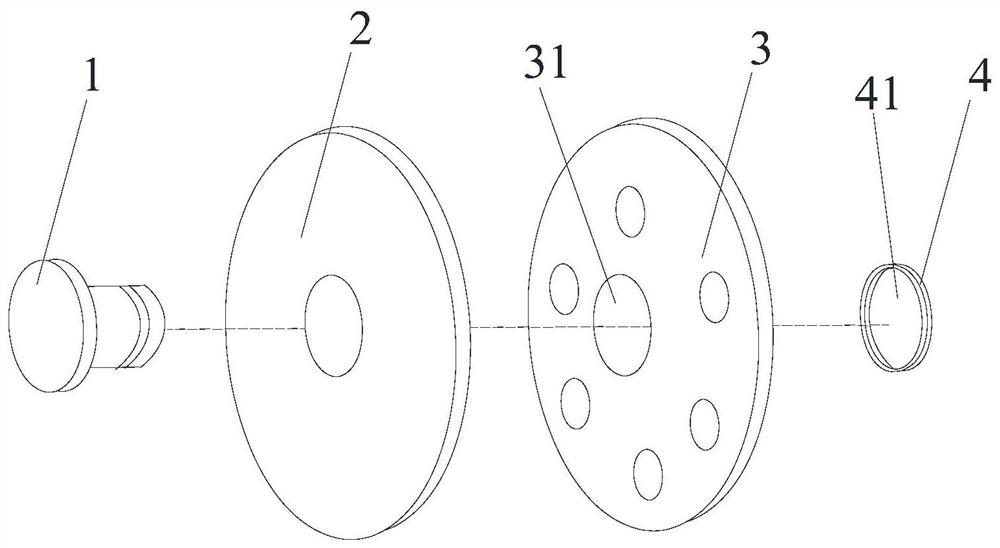

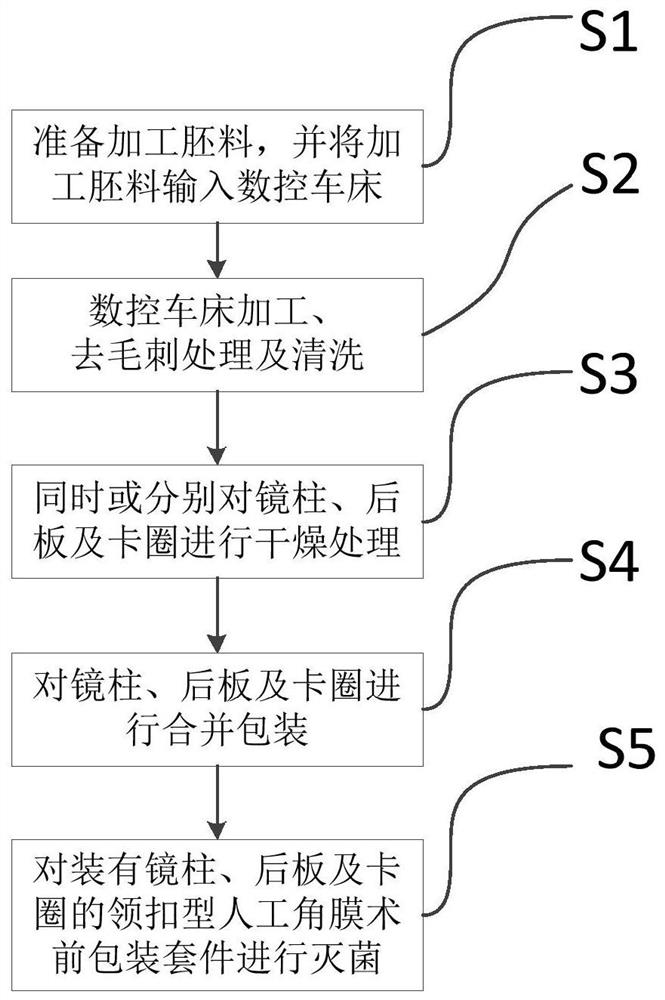

[0072] Such as figure 1 , figure 2 Shown, a kind of preparation method of buckle type artificial cornea is applied to the collar buckle type artificial cornea ( figure 1 The serial number 2 in is the production process of corneal graft), and this preparation method comprises the following steps:

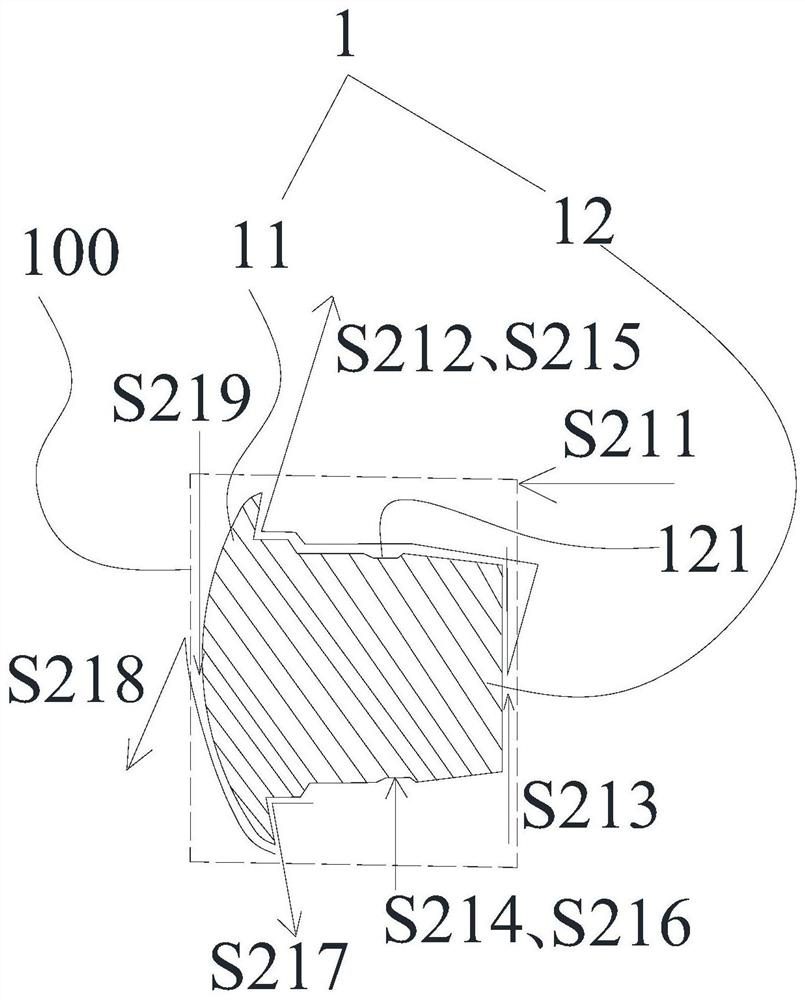

[0073] S1, prepare the processed blank, and input the processed blank into the CNC lathe; use the transparent rod as the first processed blank 100 of the mirror column 1, use the metal rod as the second processed blank 300 of the rear plate 3, and use another A metal bar is used as the third processing blank 400 of the collar 4; specifically, the transparent bar, the metal bar, and another metal bar are transported into the numerical control lathe through an automatic feeding device;

[0074] S2, use the first CNC lathe to machine the corresponding first processing blank 100 into the mirror column 1 according to the set first processing program, and then clean the processed mirror...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com