Step-by-step automatic installation device and method for geophone used for TBM excavation detection

An automatic installation and detector technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of time-consuming and labor-intensive installation, easily damaged coupling quality, distance error, etc., to achieve simple installation, improve efficiency and quality, and facilitate construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

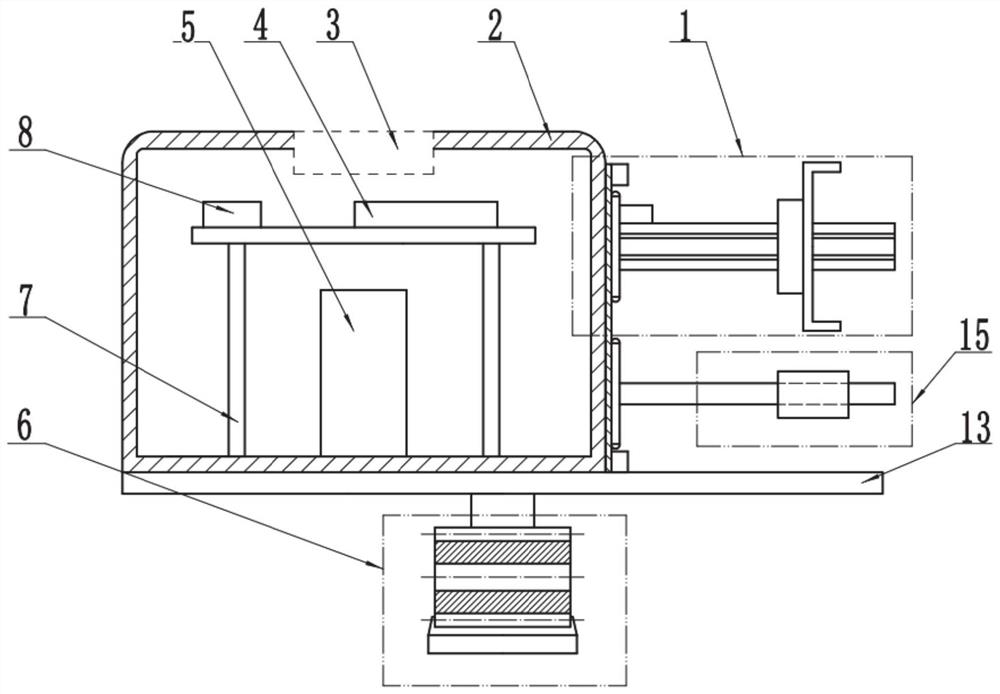

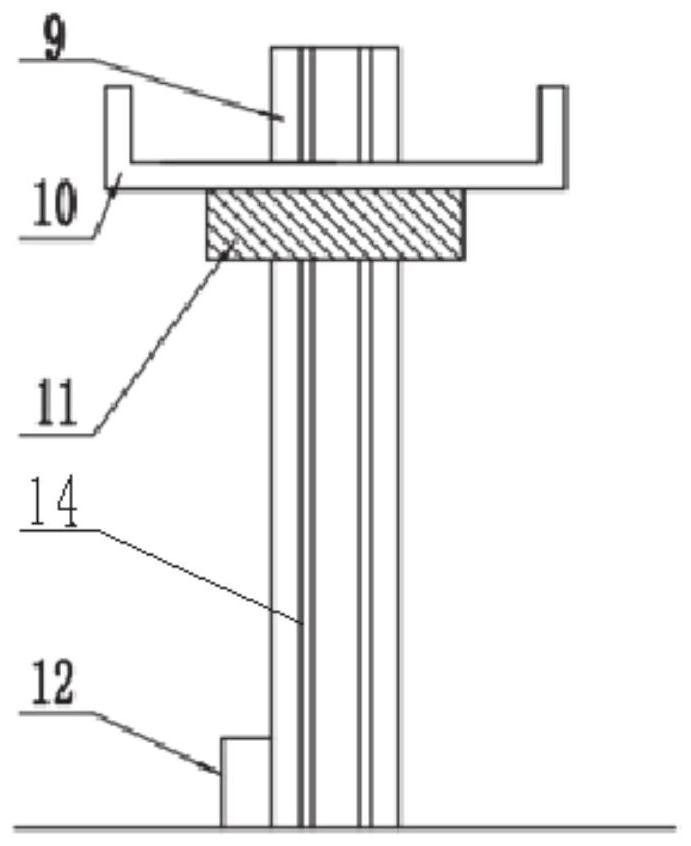

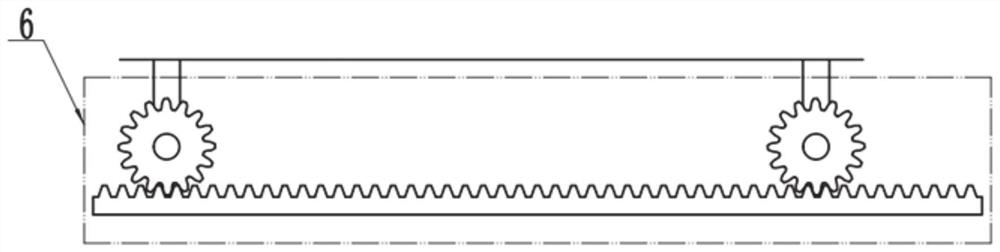

[0043] Such as figure 1 , figure 2 and image 3 As shown, Embodiment 1 of the present disclosure provides a step-by-step automatic installation device for geophones used for TBM excavation detection, including: clamping mechanism 1, housing 2, display unit 3, circuit system 4, drive motor 5, gears Device 6, bracket 7, distance sensor 8, mounting base 13 and drilling mechanism 15.

[0044] Wherein the clamping mechanism 1 includes a fixed frame 9, a grasping mechanism 10 and a clamping mechanism 11; the controller in the circuit system drives the clamping mechanism 11 to slide along the lifting slide rail 14 through the lifting mechanism 12, and drives the motor 5 and gears through reasonable design The parameters of the device 6 can realize the adjustment of the installation distance of the geophones.

[0045] In this embodiment, the outer surface of the upper part of the shell 2 is provided with a cable lead socket and a transparent material window, and the power supply o...

Embodiment 2

[0060] Such as Figure 4 and Figure 5 As shown, Embodiment 2 of the present disclosure provides a step-by-step automatic installation method for geophones for excavation detection with TBM, using the step-by-step automatic installation device for geophones for excavation detection with TBM described in Embodiment 1 of the present disclosure , including the following steps:

[0061] The distance detection element detects the distance between the current position and the previous detector in real time, and sends it to the controller in the circuit system;

[0062] The controller determines the drilling position of the next geophone according to the obtained real-time distance, drives the drilling mechanism to drill holes at the drilling position through the driving mechanism, and injects couplant into the holes;

[0063] The controller controls the track wheel to move along the track, and places the geophone at the drilling position by controlling the clamping mechanism.

[...

Embodiment 3

[0068] Embodiment 3 of the present disclosure provides a full-face hard rock tunnel boring machine, including the step-by-step automatic installation device for geophones described in Embodiment 1 of the present disclosure for detection along with TBM excavation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com