Microchannel membrane distillation assembly and device and method of enhancing membrane distillation transfer process with microchannel

A technology of microchannel and membrane distillation, applied in the field of membrane distillation, can solve the problems of limited weakening of polarization phenomenon, complex equipment structure, cumbersome implementation methods, etc., and achieve the effects of easy promotion and use, high membrane flux, and simplified preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

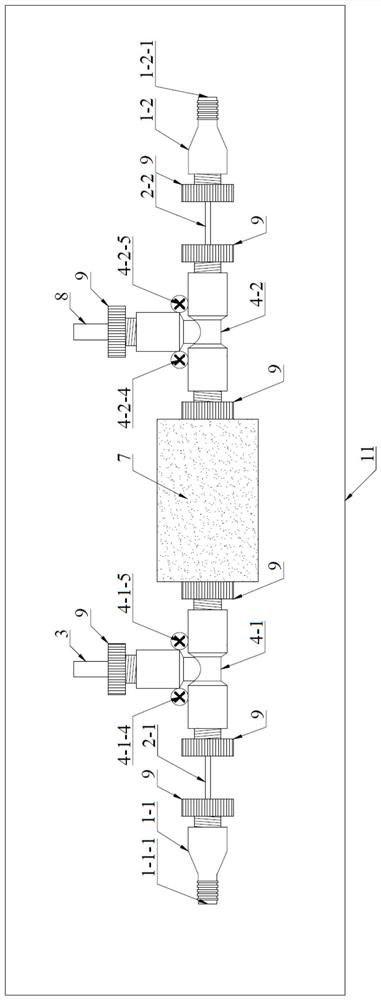

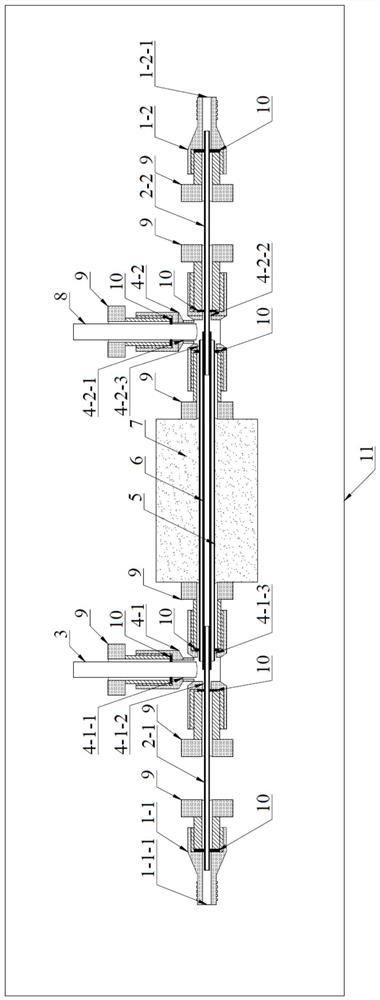

[0040] In this embodiment, the microchannel membrane distillation assembly such as figure 1 , figure 2 Shown, by base 11, hydrophobic microporous hollow fiber membrane 6, outer tube 5, insulation layer 7, the first tee 4-1, the second tee 4-2, the first capillary 2-1, the second capillary 2 -2. The first two-way 1-1, the second two-way 1-2, the liquid inlet pipe 3, the liquid outlet pipe 8, the joint 9 and the sealing ring 10 are combined.

[0041] The material of the hydrophobic microporous hollow fiber membrane 6 is polyvinylidene fluoride, the length is 200 mm, the inner diameter is 0.8 mm, the outer diameter is 1.2 mm, the porosity is 0.60, and the average pore diameter of the membrane is 0.1 μm; the outer tube 5 The material is plexiglass, the length is 150 mm, the inner diameter is 1.8 mm, and the outer diameter is 3 mm; the material of the first capillary 2-1 and the second capillary 2-2 is stainless steel, the length is 100 mm, the inner diameter is 0.6 mm, and the o...

Embodiment 2

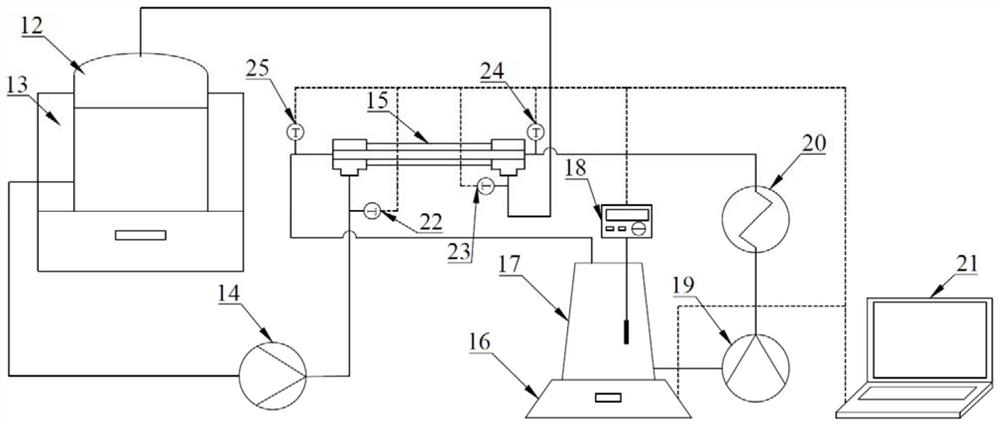

[0050] In this embodiment, the microchannel membrane distillation device such as image 3 Shown, by feed liquid circulation tank 12, the heating water bath pot 13 that heating feed liquid is used, the first transfer pump 14, electronic balance 16, cold liquid collecting tank 17, conductivity meter 18, the second transfer pump 19, constant temperature water bath pot 20. A computer 21, a first temperature sensor 22, a second temperature sensor 23, a third temperature sensor 24, a fourth temperature sensor 25, and the microchannel membrane distillation assembly 15 with the structure described in Embodiment 1.

[0051] The liquid outlet of the feed-liquid circulation tank 12 is connected with the liquid inlet of the first transfer pump 14 through a pipe fitting, and the liquid outlet of the first transfer pump 14 is connected with the shell-side microchannel of the microchannel membrane distillation assembly 15 through a pipe fitting The liquid inlet is connected, and the shell-si...

Embodiment 3

[0054] In this embodiment, the microchannel membrane distillation device described in Example 2 is used for membrane distillation operation. Both the hot side fluid (feed liquid to be treated) and the cold side fluid are deionized water, and the flow mode is parallel flow. The operation steps are as follows:

[0055] 1. Open the electronic balance 16, the conductivity meter 18, each temperature sensor and the computer 21 in the microchannel membrane distillation device;

[0056] ② Turn on the heating water bath 13 in the microchannel membrane distillation device, set its heating temperature to 70°C required by the hot side fluid, turn on the constant temperature water bath 20 in the microchannel membrane distillation device, and set its constant temperature to cold The required temperature of the side fluid is 20°C;

[0057] ③ heat the hot-side fluid in the feed-liquid circulation tank 12 of the microchannel membrane distillation device to 70°C with the heating water bath (1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com