Preparation process of overflow exchange type anti-corrosion coating

A technology of anti-corrosion coating and preparation process, which is applied in the field of preparation process of overflow exchange type anti-corrosion coating, which can solve problems such as weakening of strength, deterioration of internal metal protection effect, and impossibility of complete shielding effect of coating, so as to avoid The existence of internal air, the effect of ensuring the service life and ensuring the tightness of the chamber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

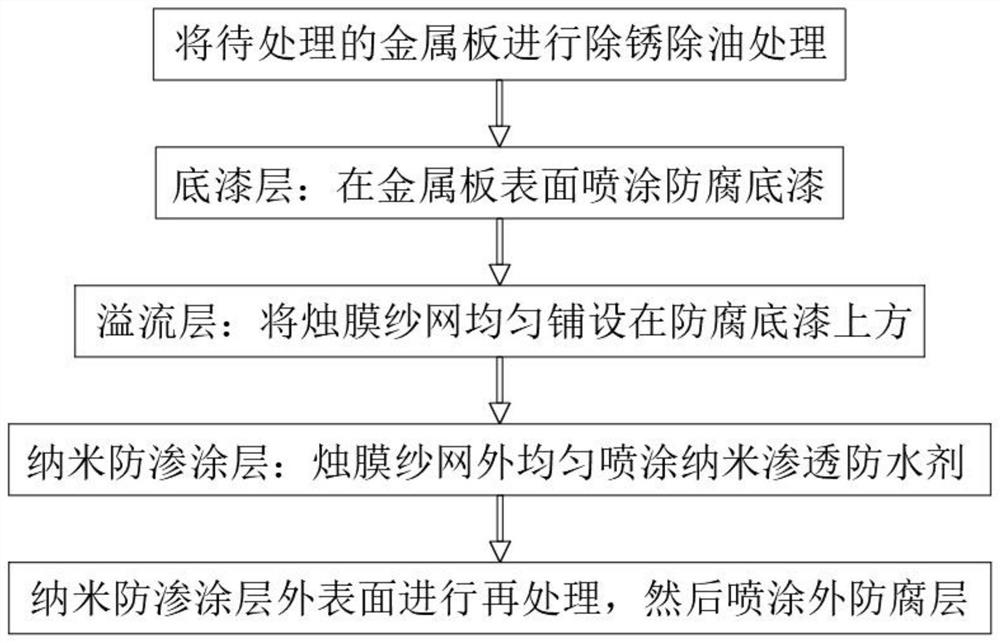

[0050] see figure 1 , an overflow exchange type anti-corrosion coating preparation process, comprising the following steps:

[0051] S1. First, the metal plate to be treated is cleaned to remove rust and oil;

[0052] S2, spray anti-corrosion primer on the surface of the metal plate to form a primer layer;

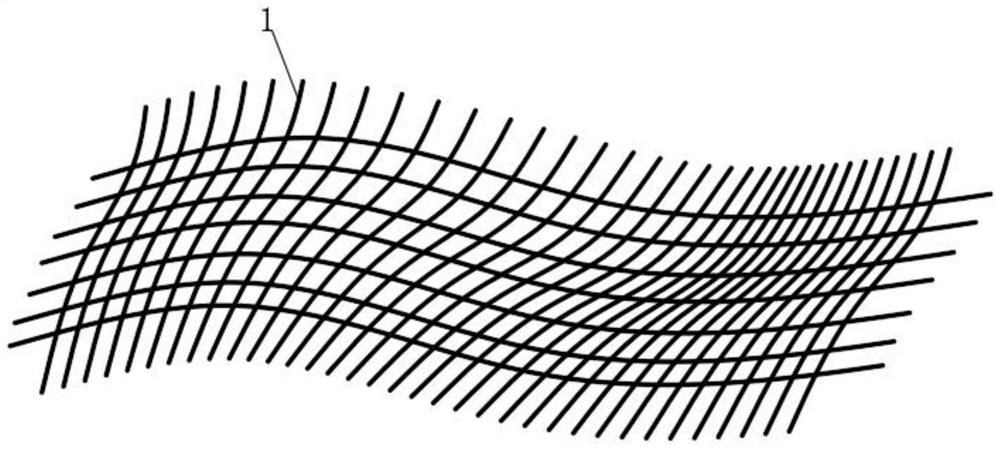

[0053] S3, the gauze is pretreated to obtain a candle film gauze, and then the candle film gauze is evenly laid on the top of the anti-corrosion primer to form an overflow layer;

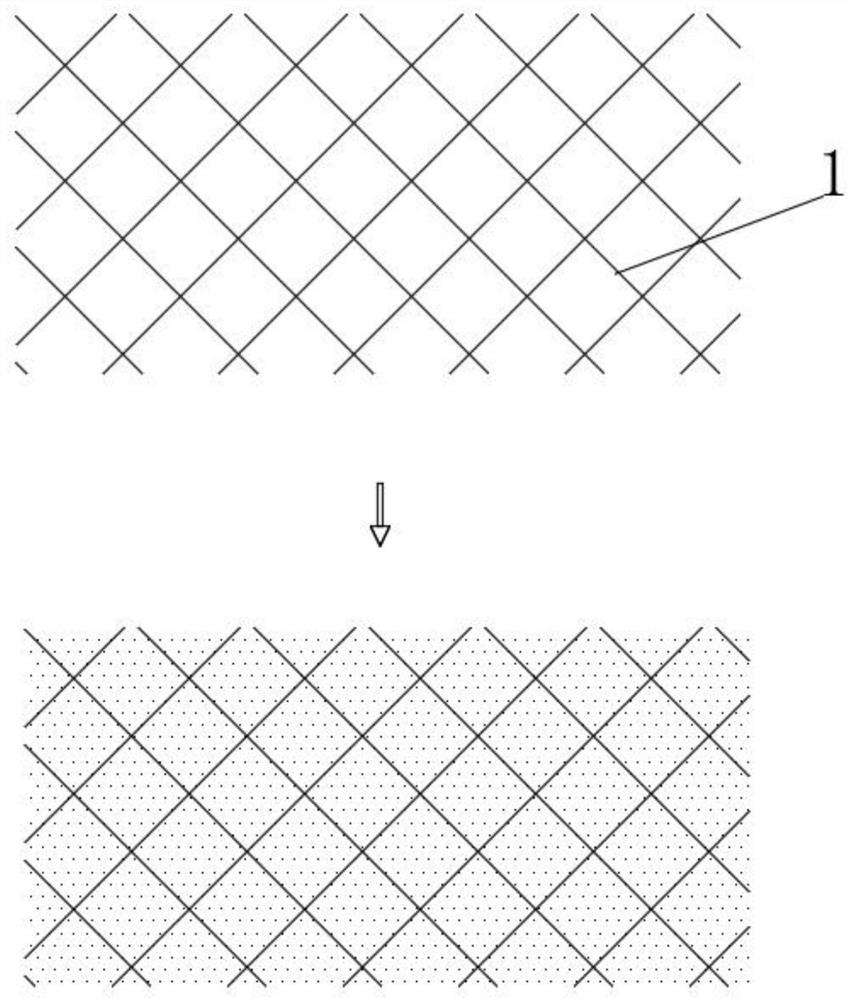

[0054] see figure 2 , the candle film gauze preparation steps are specifically:

[0055] S31. First, irradiate the gauze made of glass filaments with ultraviolet rays at high temperature, and perform dehumidification and insect removal treatment, so as to effectively avoid microbial erosion inside the anti-corrosion layer, thereby effectively ensuring the service life of the anti-corrosion layer;

[0056] S32, then flatten the gauze and immerse it in the wax oil in the molten state, then pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com