Optical lens, optical lens forming die and manufacturing method thereof

A technology for forming molds and optical lenses, which is applied in optics, lenses, optical components, etc., can solve problems such as uneven quality, affecting optical transmission paths, and difficult processing, and achieves the effects of simple manufacturing process, uniform dispersion of light beams, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following examples illustrate possible implementations of the present invention, but are not intended to limit the protection scope of the present invention.

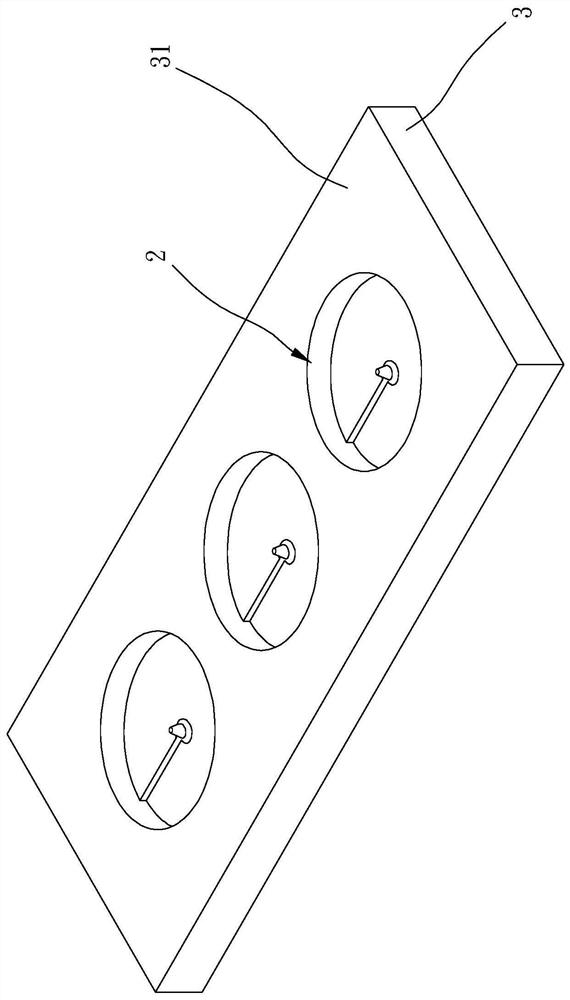

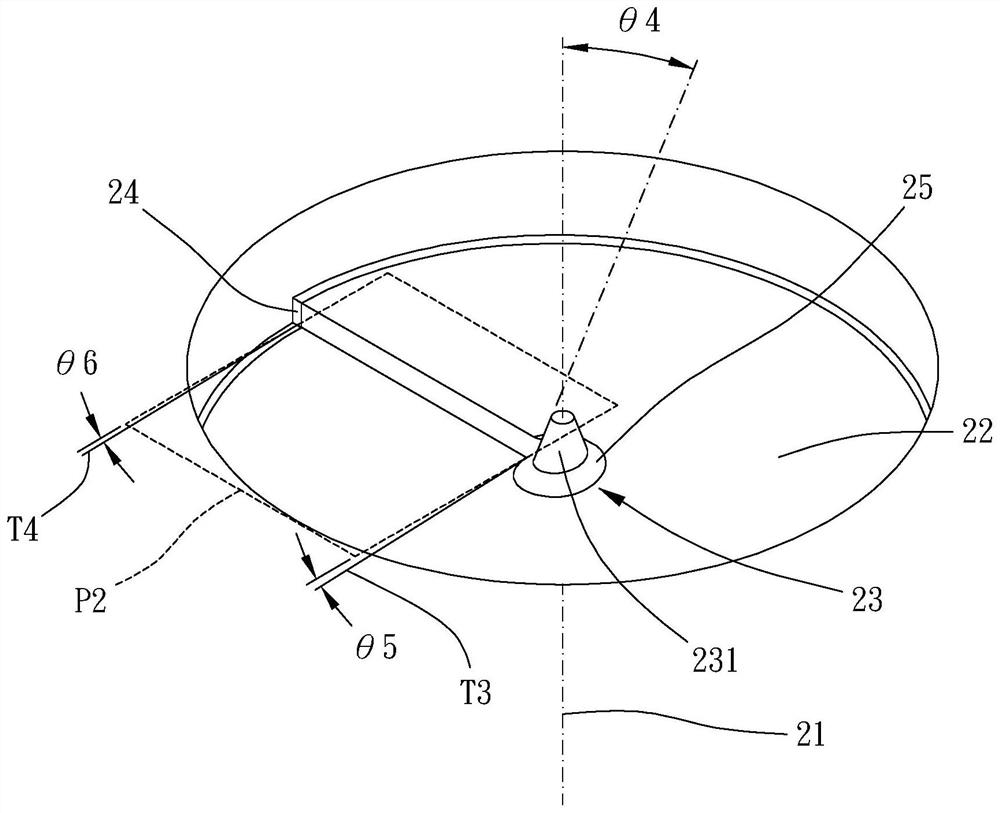

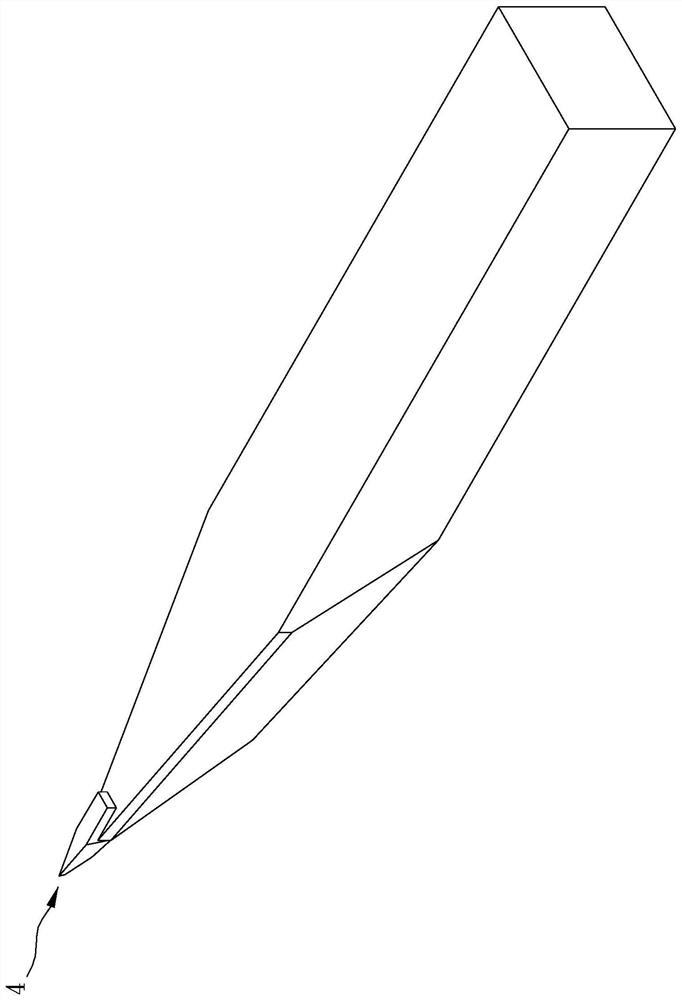

[0037] Please refer to Figures 1 to 5 , which shows a molding die 2 for manufacturing the following optical lens according to a preferred embodiment of the present invention, which includes a helical surface 22 spiraling around an axial direction 21 and an intermediate structure wound by the helicoidal surface 22 23 , the intermediate structure 23 of the molding die 2 extends axially toward one side relative to the helical surface 22 of the molding die 2 , and the helical surface 22 of the molding die 2 goes around to form a first step difference 24 .

[0038] In this embodiment, the intermediate structure 23 of the molding die 2 is a convex column, and the diameter of the end surface of the convex column is greater than or equal to 0.001 mm and less than or equal to 0.02 mm; the intermediate structure 23 of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arc radius | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| First angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com