A multi-chamber gas pool

A multi-gas chamber and gas pool technology, applied in the field of laser frequency conversion, can solve the problems of rising and hot gas with small specific gravity, and reduce the quality of the output beam, so as to achieve the effects of reducing heat accumulation, high work efficiency, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

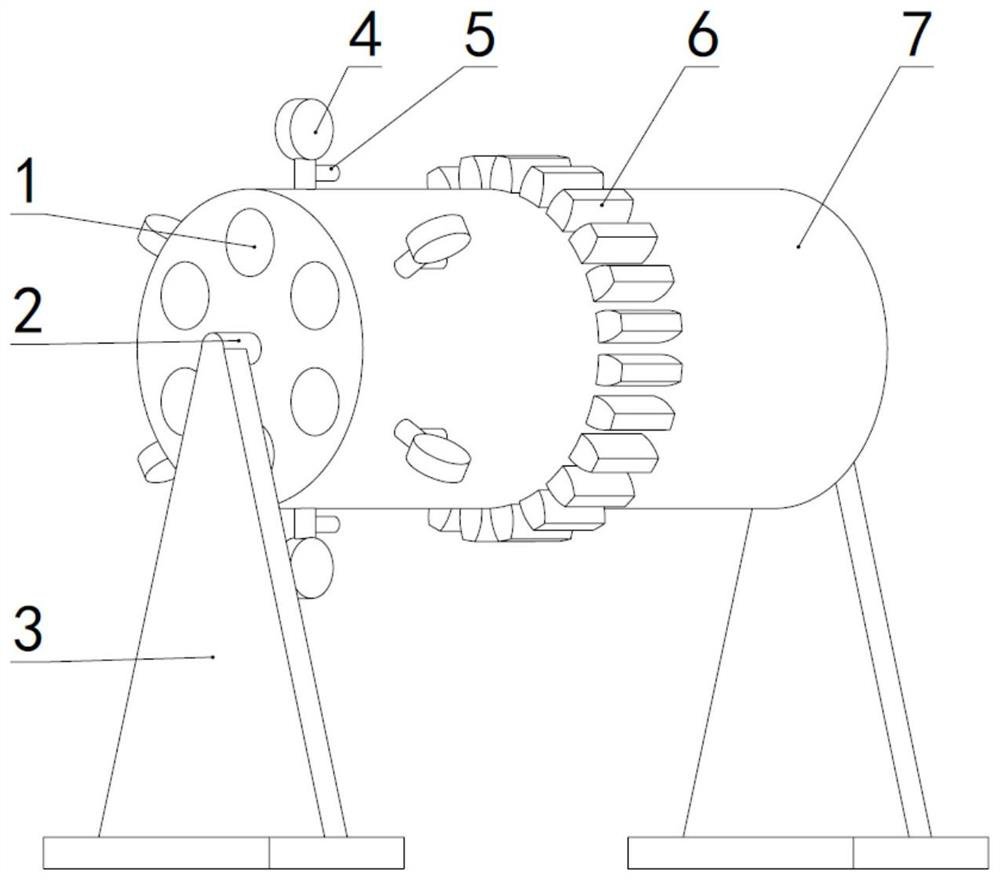

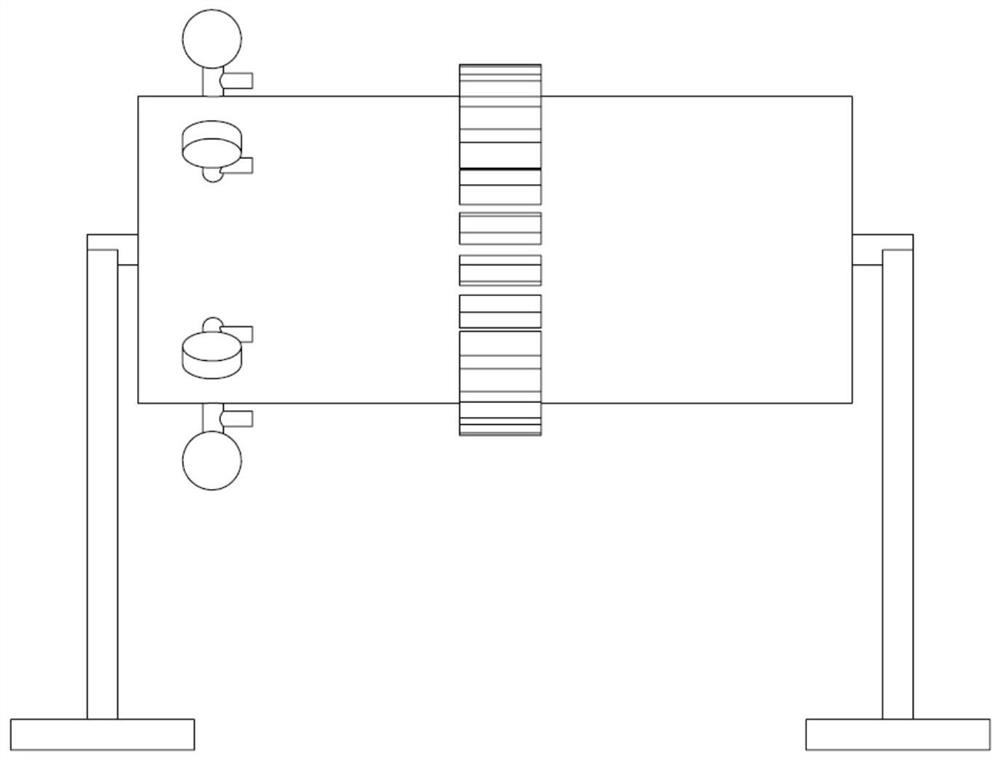

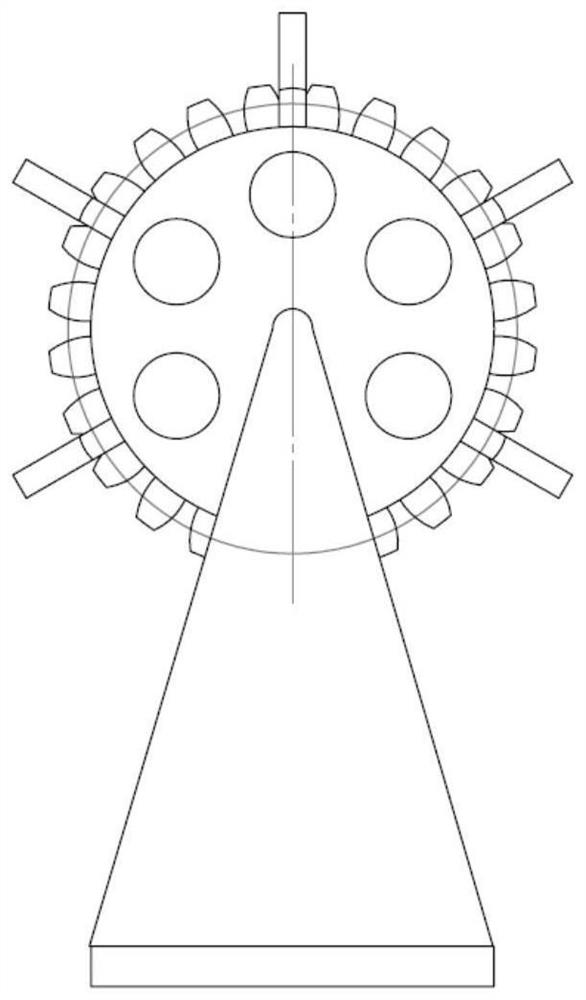

[0024] Such as figure 1 As shown, a multi-chamber gas pool includes a window (1), a rotating bearing (2), a gas pool bracket (3), a barometer (4), a ventilation valve (5), a rotating gear (6), and multiple Gas chamber stainless steel pool body (7), the two ends of the multi-gas chamber stainless steel pool body (7) are connected to the gas pool bracket (3) through rotating bearings (2), and there are 6 internal arrays of the multi-gas chamber stainless steel pool body (7) Independent air chambers, windows (1) are installed at both ends of the six air chambers, and the six air chambers are equipped with air pressure gauges (4) and ventilation valves (5); the rotating gears (5) are located The outer side of the multi-air chamber pool body (7) is distributed radially and circumferentially.

[0025] The technical solution is: use a high-repetition laser with a wavelength of 1064nm, a spot diameter of 6mm, and a repetition rate of 100Hz as the incident laser. The gas pool contains...

Embodiment 2

[0027] Such as figure 1 As shown, a multi-chamber gas cell, the technical solution is: use a high repetition rate laser with a wavelength of 1064nm, a spot diameter of 6mm, and a repetition rate of 100Hz as the incident laser. The gas cell contains 6 independent gas cells, and each gas cell A plano-convex window with a diameter of 10mm and a front and rear window thickness of 10mm. The front and rear lens windows are confocal, and the sum of the focal lengths of the two front and rear lenses is equal to the length of the independent air chamber. The material is quartz, and the inside of the air chamber is filled with 2MPa high Pure methane gas. First let the incident laser pass completely through one of the gas chambers, and then start the drive motor to rotate the gas cell at a certain speed. By adjusting the speed, the rotation interval of each gas chamber is an integer multiple of the pulse interval of the incident laser. Therefore, each The independent air chamber rotates...

Embodiment 3

[0029] Such as figure 1 As shown, a multi-chamber gas cell, the technical solution is: use a high repetition rate laser with a wavelength of 532nm, a spot diameter of 10mm, and a repetition rate of 50Hz as the incident laser. The gas cell contains 4 independent gas cells, and each gas cell The diameter is 15mm, the thickness of the front and rear windows is 10mm, the material is quartz entrance window with anti-reflection coating @532nm, exit window with anti-reflection coating @495nm&463nm&435nm&532nm&624nm&683nm, each gas chamber is filled with 3MPa, 2MPa, 1MPa, 0.5 MPa high-purity carbon dioxide gas. First let the incident laser pass completely through one of the gas chambers, and then start the drive motor to rotate the gas cell at a certain speed. By adjusting the speed, the rotation interval of each gas chamber is an integer multiple of the pulse interval of the incident laser. Therefore, each The independent air chamber rotates after passing through one or more laser p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com