Preparation method of vegetable gel soft sweets

A kind of gel, vegetable gum technology, applied in confectionery, confectionery industry, food science and other directions, can solve the problems of carrageenan gum base hardness, brittleness, not enough elasticity, soft candy seepage and other problems, to improve Overall taste, improved brittleness, improved water retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

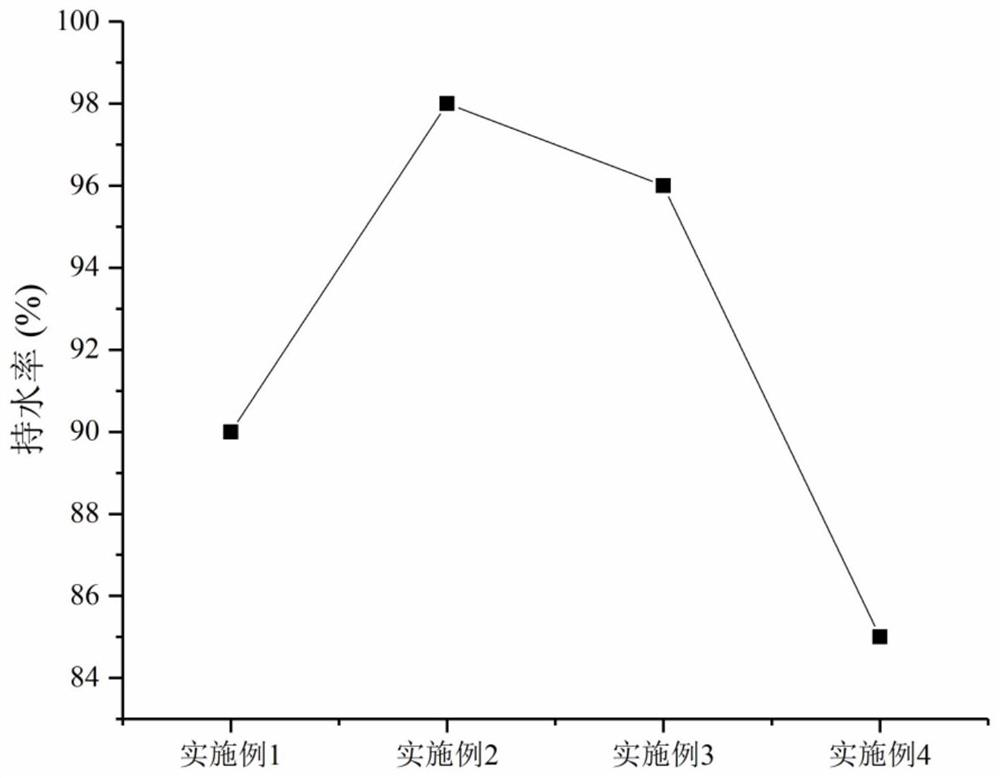

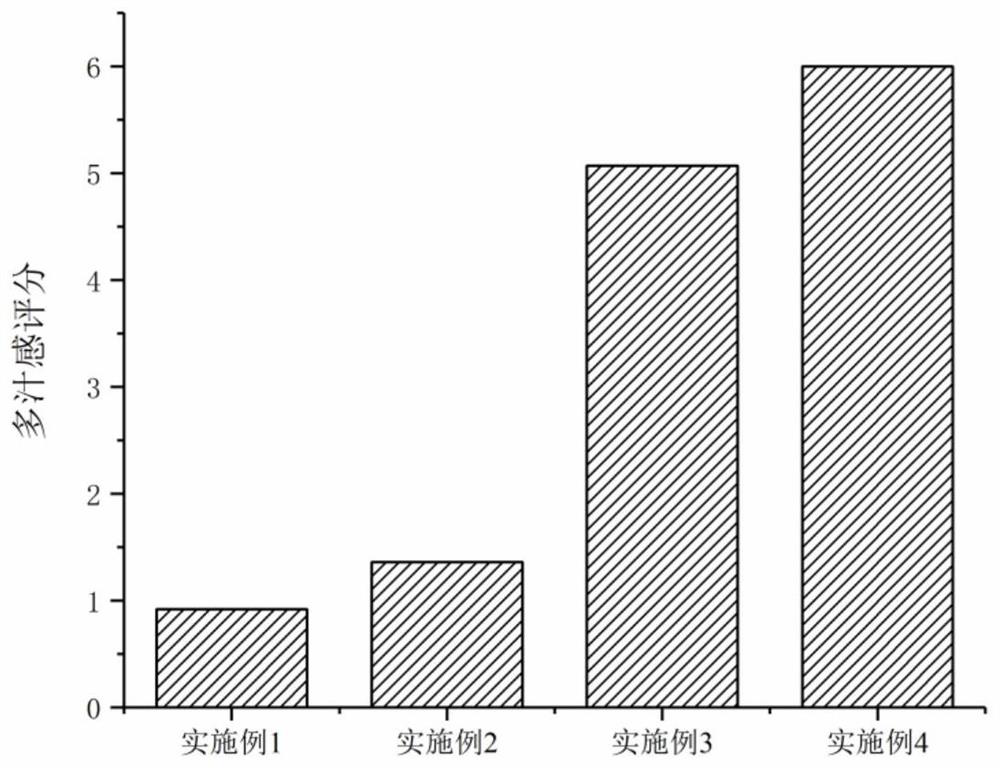

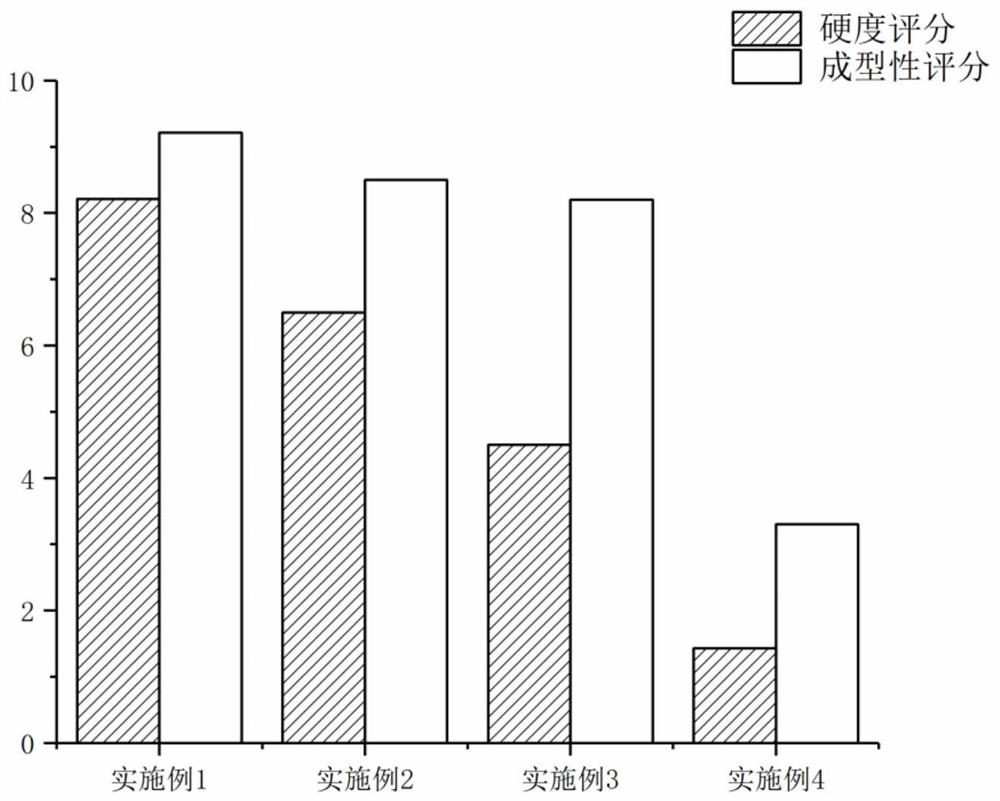

Embodiment 1

[0031] This embodiment includes the following raw materials in mass fractions: 40 parts of water, 40 parts of white granulated sugar, 60 parts of fructose syrup, 20 parts of concentrated fruit juice, 3 parts of food grade glycerin, 4 parts of κ-carrageenan, 2 parts of citric acid, citric acid 1 part of sodium, 0.25 part of dipotassium hydrogen phosphate, appropriate amount of food flavor and pigment, and deionized water.

[0032] This example is prepared according to the following steps: uniformly mix carrageenan and white sugar to obtain gum powder A, set aside, mix citric acid, sodium citrate, dipotassium hydrogen phosphate and 10 parts of water, heat and dissolve completely to obtain a sour agent solution , keep warm in a water bath at 90°C; mix the fruit juice and glycerin evenly, add the sour agent solution prepared in the above steps, and mix evenly to obtain a mixed solution B for later use; after mixing the fructose syrup and 40 parts of water evenly, add the above The...

Embodiment 2

[0034] This embodiment includes the following raw materials in mass fractions: 40 parts of water, 40 parts of white granulated sugar, 60 parts of fructose syrup, 20 parts of concentrated fruit juice, 3 parts of food grade glycerin, 3.2 parts of κ-carrageenan, 2 parts of citric acid, citric acid 1 part of sodium, 0.8 part of CMC, 0.25 part of dipotassium hydrogen phosphate, appropriate amount of food flavor and pigment, and deionized water.

[0035] This example is prepared according to the following steps: mix carrageenan, CMC and white sugar evenly to obtain gum powder A, set aside, mix citric acid, sodium citrate, dipotassium hydrogen phosphate and 10 parts of water, heat and dissolve to obtain a sour taste Put the sour agent solution in a 90°C water bath to keep it warm; mix the fruit juice and glycerin evenly, add the sour agent solution prepared in the above steps, and mix evenly to obtain a mixed solution B for later use; mix the fructose syrup with 40 parts of water even...

Embodiment 3

[0037] This embodiment includes the following raw materials in mass fractions: 40 parts of water, 40 parts of white granulated sugar, 60 parts of fructose syrup, 20 parts of concentrated fruit juice, 3 parts of food grade glycerin, 2.4 parts of κ-carrageenan, 2 parts of citric acid, citric acid 1 part of sodium, 1.6 parts of CMC, 0.25 parts of dipotassium hydrogen phosphate, appropriate amount of food flavor and pigment. The water in this embodiment is deionized water.

[0038]This example is prepared according to the following steps: mix carrageenan, CMC and white sugar evenly to obtain gum powder A, set aside, mix citric acid, sodium citrate, dipotassium hydrogen phosphate and 10 parts of water, heat and dissolve to obtain a sour taste Put the sour agent solution in a 90°C water bath to keep it warm; mix the fruit juice and glycerin evenly, add the sour agent solution prepared in the above steps, and mix evenly to obtain a mixed solution B for later use; mix the fructose syr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com