Vocs waste gas treatment purifier

A waste gas treatment and purifier technology, applied in the direction of gas treatment, chemical instruments and methods, membrane technology, etc., can solve the problems of low recycling rate of vocs gas, secondary pollution of adsorbent, frequent replacement of adsorbent, etc., and achieve economical treatment The effect of saving time, avoiding waste, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

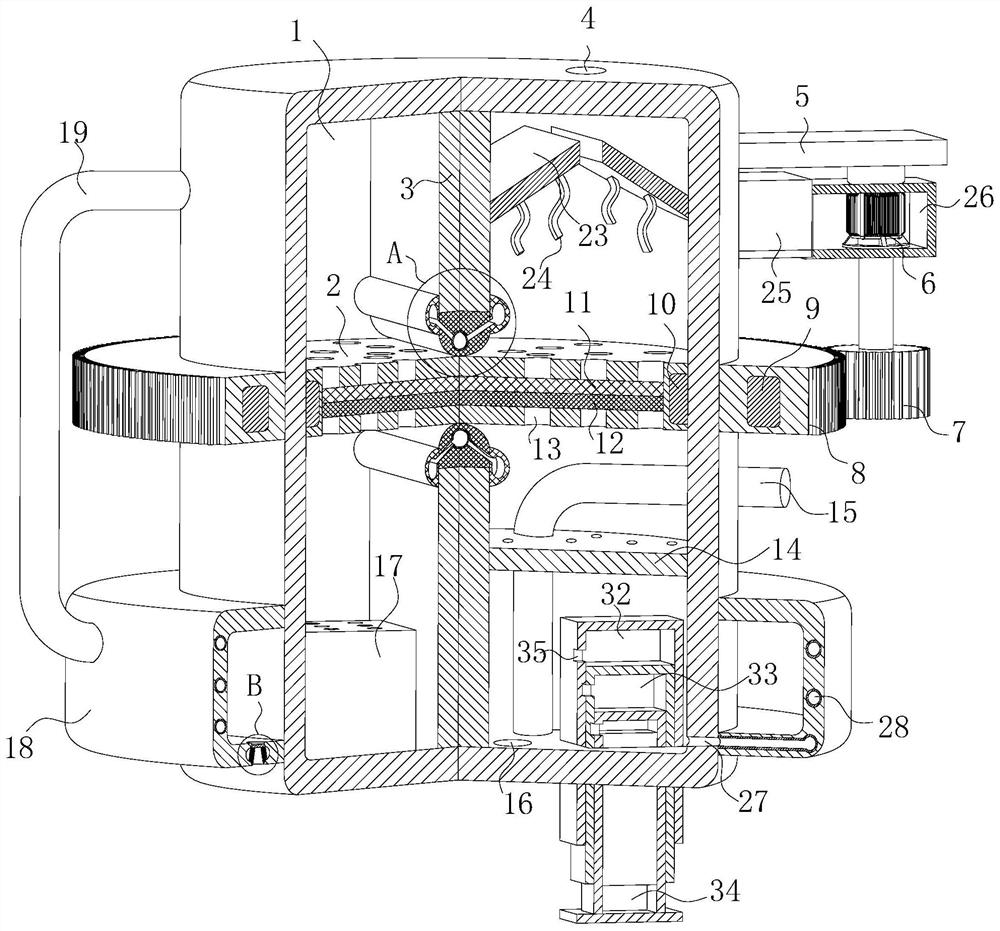

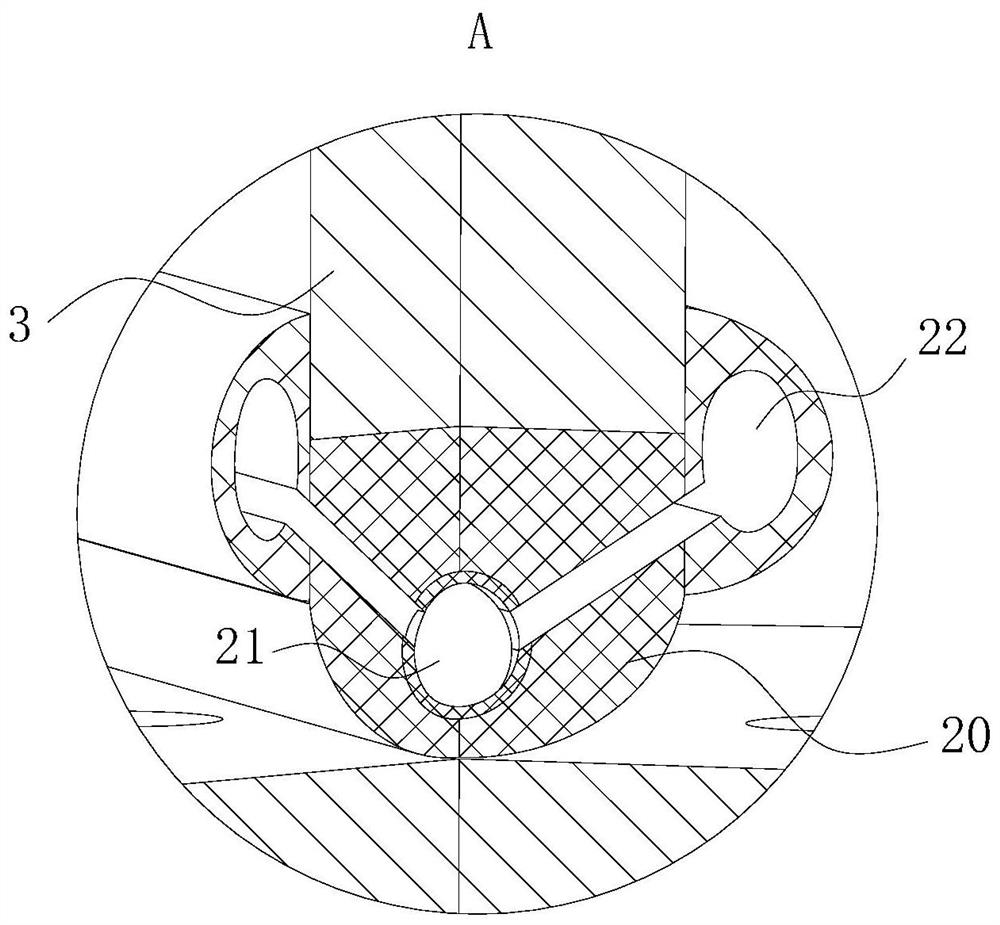

[0022] As an embodiment of the present invention, a protective layer 20 is fixedly connected to the surface of one end of the partition plate 3 relative to the rotating plate 2, and the protective layer 20 is made of an elastic wear-resistant material; The first airbag 21 with a strip design; the side surfaces of both sides of the partition plate 3 relative to one end of the rotating plate 2 are fixed with a second airbag 22 with a strip design, and the second airbag 22 and the first airbag 21 pass through The airway is connected, and the second airbag 22 is filled with gas inside the first airbag 21; during operation, the gas in the reaction tank 1 increases, and the air pressure increases, and the gas in the compressed second airbag 22 enters the first airbag 21, and the first airbag 21 The expansion makes the partition 3 and the rotating plate 2 more closely contact, effectively improves the sealing between the partition 3 and the rotating plate 2, prevents the gas circulati...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap