High-CO-concentration flue gas coupling low-temperature SCR temperature control method and system

A temperature control method and flue gas technology, applied in the field of flue gas purification, can solve problems affecting the denitrification reaction process, flue gas temperature fluctuations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

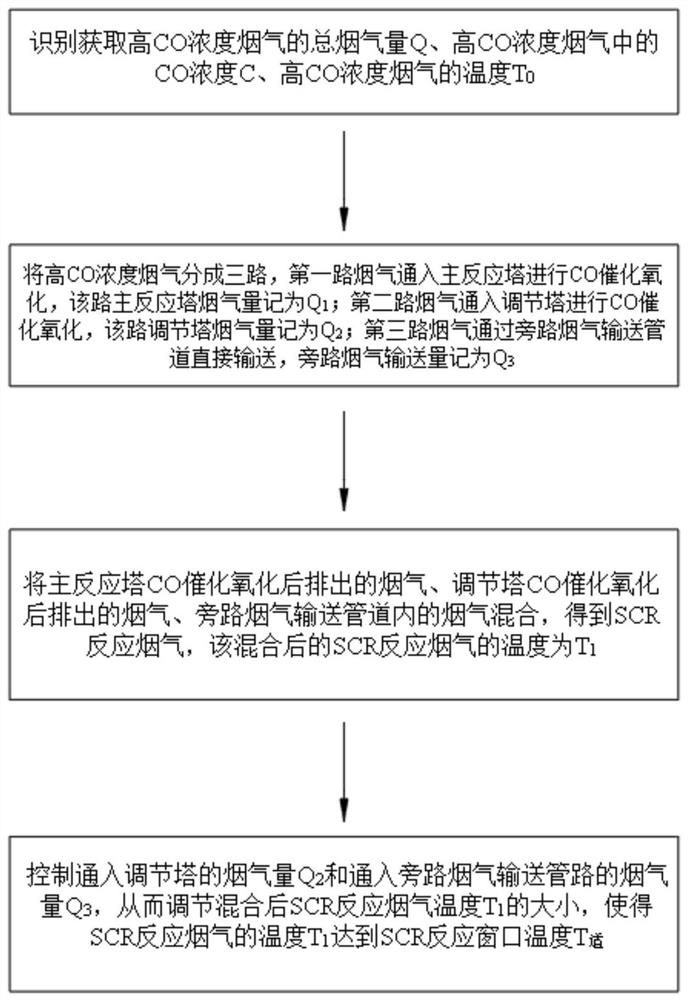

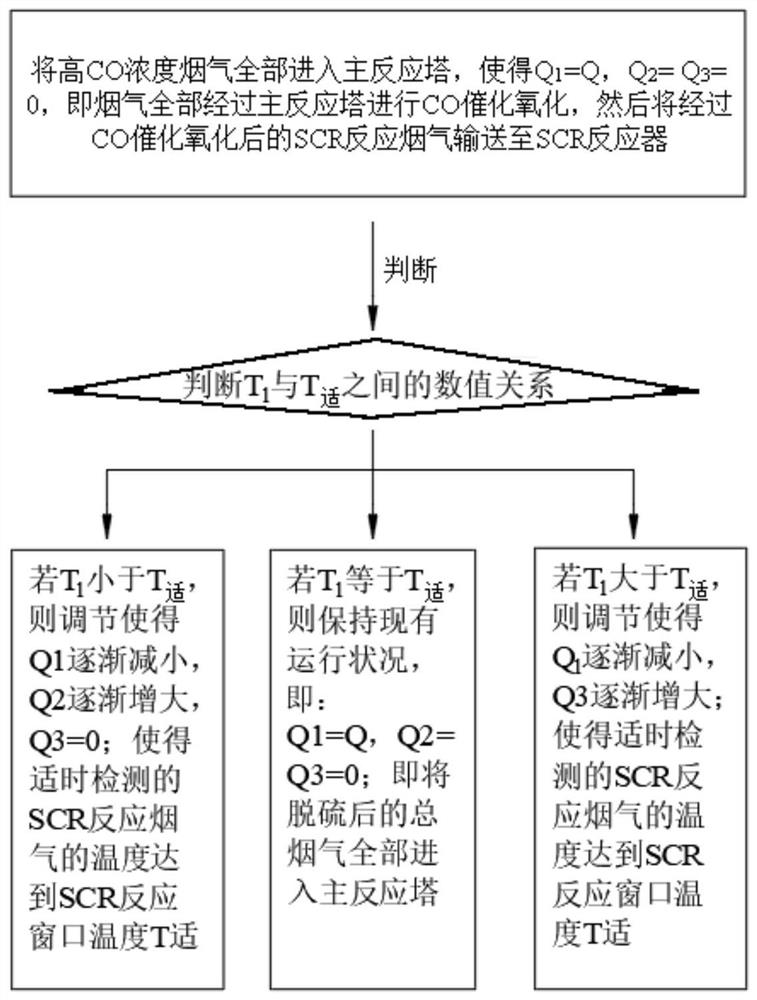

Method used

Image

Examples

Embodiment 1

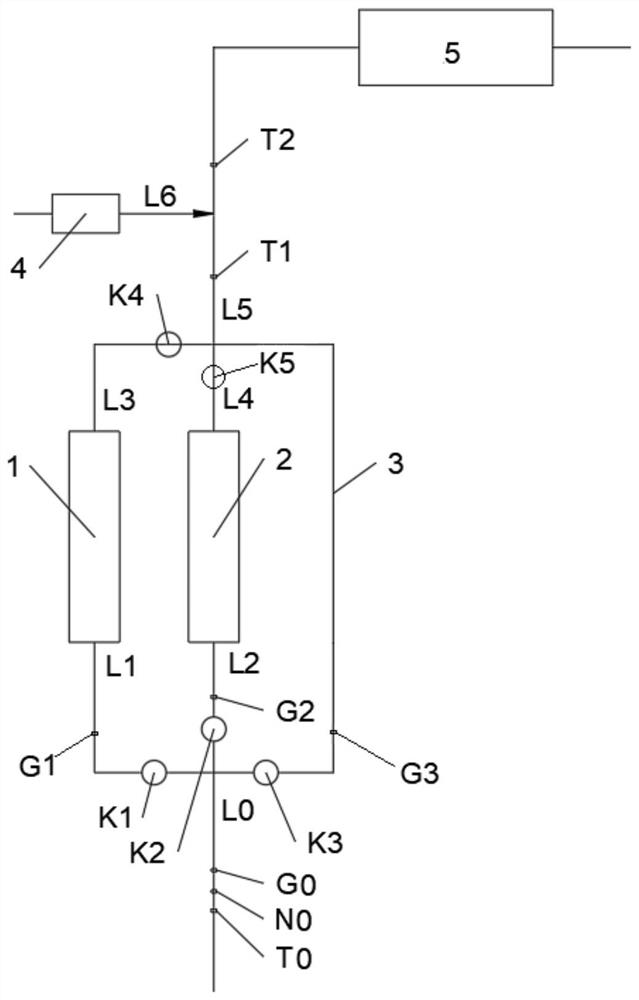

[0103] Such as image 3 As shown, a system for high CO concentration flue gas coupled with low temperature SCR temperature control treatment, the system includes: CO main reaction tower 1, CO adjustment tower 2, bypass flue gas delivery pipeline 3. The total flue gas pipeline L0 with high CO concentration flue gas is divided into three paths: the first pipeline L1 is connected to the CO main reaction tower 1, the second pipeline L2 is connected to the CO regulating tower 2, and the bypass flue gas transmission pipeline 3 is connected. The CO main reaction tower 1 discharges the flue gas after CO catalytic oxidation through the third pipeline L3, and the CO adjustment tower 2 discharges the flue gas after CO catalytic oxidation through the fourth pipeline L4. The ends of the third pipeline L3, the fourth pipeline L4, and the bypass flue gas conveying pipeline 3 are merged into the fifth pipeline L5. The end of the fifth pipe L5 is connected to the SCR reactor 5 .

Embodiment 2

[0105] Embodiment 1 is repeated, except that the first air valve K1 is provided on the first pipeline L1. A second air valve K2 is provided on the second pipeline L2. The bypass flue gas delivery pipe 3 is provided with a third gas valve K3.

Embodiment 3

[0107] Repeat Example 2, except that the device also includes: the original flue gas temperature sensor T0, the original flue gas CO concentration detection sensor N0, the original flue gas flow sensor G0, the first gas flow sensor G1, the second gas flow sensor G2, The third gas flow sensor G3. The raw flue gas temperature sensor T0, the raw flue gas CO concentration detection sensor N0, and the raw flue gas flow sensor G0 are arranged on the main flue gas pipeline L0. The first gas flow sensor G1 is arranged on the first pipeline L1. The second gas flow sensor G2 is disposed on the second pipeline L2. The third gas flow sensor G3 is arranged on the bypass flue gas delivery pipe 3 . The fifth pipeline L5 is provided with a first temperature measuring sensor T1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com