Opacified peacock green high-alumina glass and preparation method thereof

A technology of high-alumina glass and malachite green, which is applied in the field of glass manufacturing, can solve problems such as shedding, poor coloring effect, and coating aging, and achieve the effects of low cost, simple preparation process, and broad development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

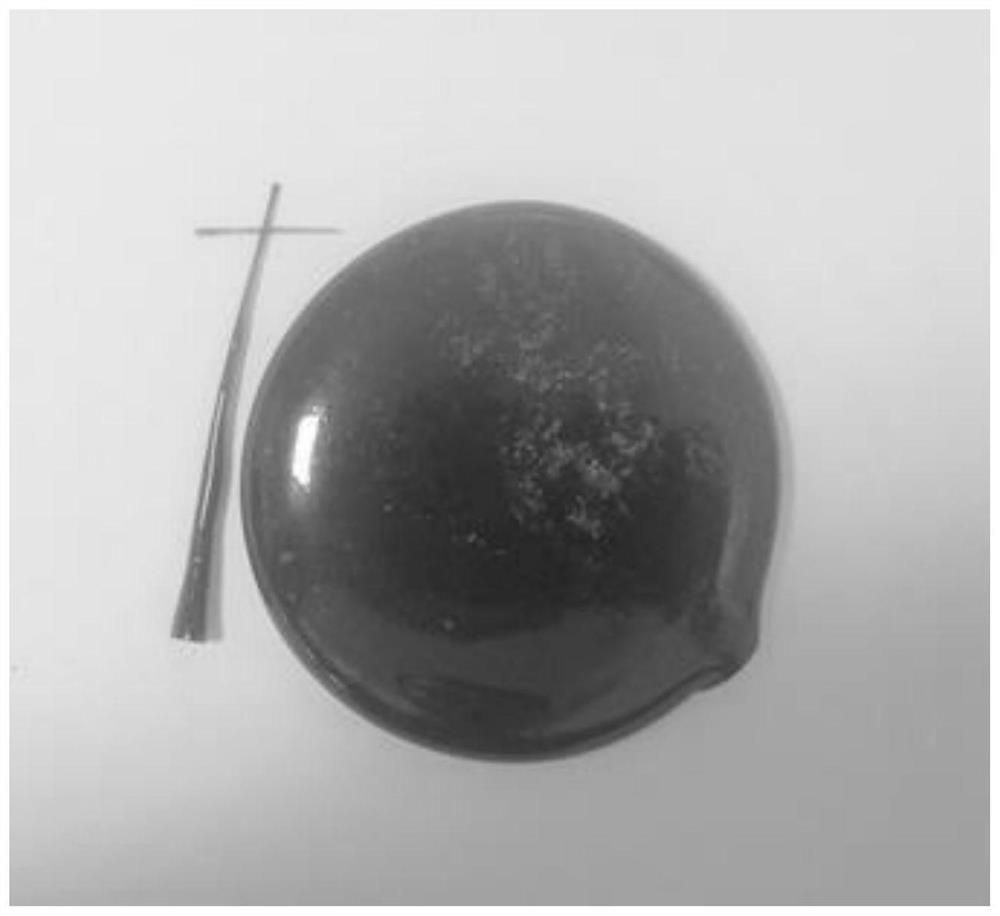

Image

Examples

Embodiment 1~7

[0020] In this embodiment, the following method is adopted to prepare high alumina glass material:

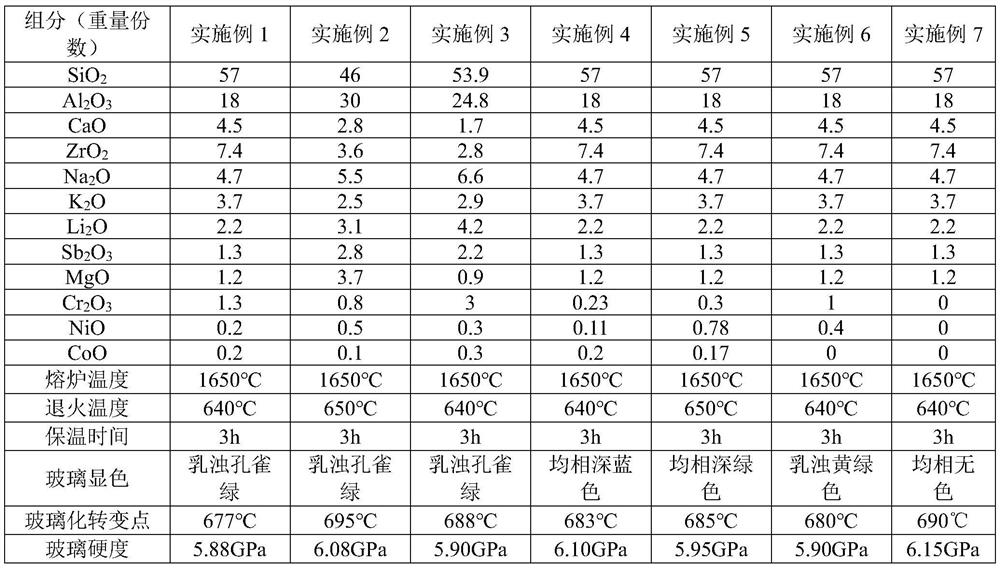

[0021] (1) Prepare glass batch according to the components described in Table 1 below;

[0022] (2) The glass batch material is melted into molten glass in a high-temperature furnace with an oxidizing atmosphere, and the melting temperature is 1650°C;

[0023] (3) Pour the molten glass into the mold for rapid cooling, then anneal it, keep it warm for 3 hours and then cool it in the furnace.

[0024] Table 1 Example 1 ~ 7 glass batch composition and ratio

[0025]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com