Method for separating by-products in process for preparing methyl formate by carbonylation of methanol

A technology of methanol carbonylation and methyl formate, which is applied in the separation/purification of carboxylic acid compounds, chemical instruments and methods, and the preparation of organic compounds, etc. It can solve the problems of low degree of automation, manual cleaning of nozzles, and large environmental pollution. It achieves the effects of high degree of automation, good desalination effect and low environmental risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

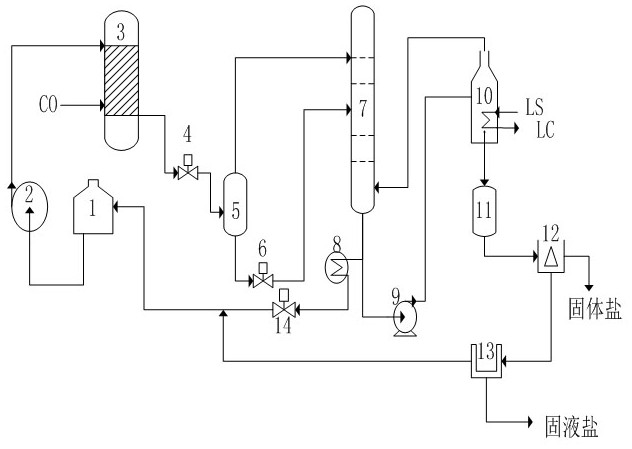

[0018] Below in conjunction with accompanying drawing and preferred embodiment, to the specific embodiment, structure, characteristic and effect of the separation method of by-product sodium formate in a kind of methanol carbonylation process of producing methyl formate proposed by the present invention, structure, characteristic and effect thereof, describe in detail as follows.

[0019] see figure 1 Shown, the separation method of by-product sodium formate in a kind of methyl formate carbonylation process of methanol, comprises the following steps:

[0020] (1) The methanol in the dry methanol storage tank 1 is pressurized by the methanol feed pump 2 and then enters the methyl ester reactor 3. Under the action of the catalyst, the carbonylation reaction and side reactions occur, and the product after the reaction (20-30% methyl formate) After being decompressed to 0.5-0.6 MPa through the product extraction valve 4, it enters the gas-liquid separation tank 5 to flash CO gas; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com