Flash sintering preparation method of uranium-zirconium hydride and uranium-yttrium hydride fuel pellets

A fuel pellet, zirconium hydride technology, applied in the direction of moderator/core structure, nuclear power generation, climate sustainability, etc., can solve the problems of complex process, low density, high process difficulty, etc., and achieve short duration , The effect of shortening the flash sintering time and uniform distribution of the two phases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

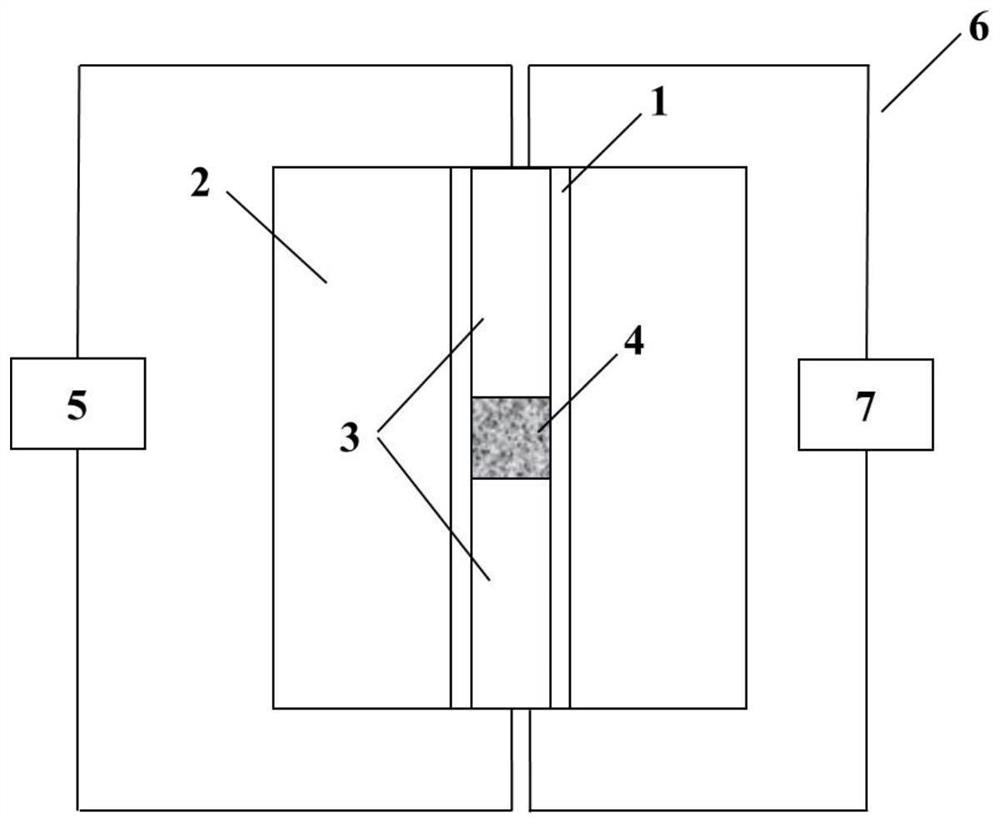

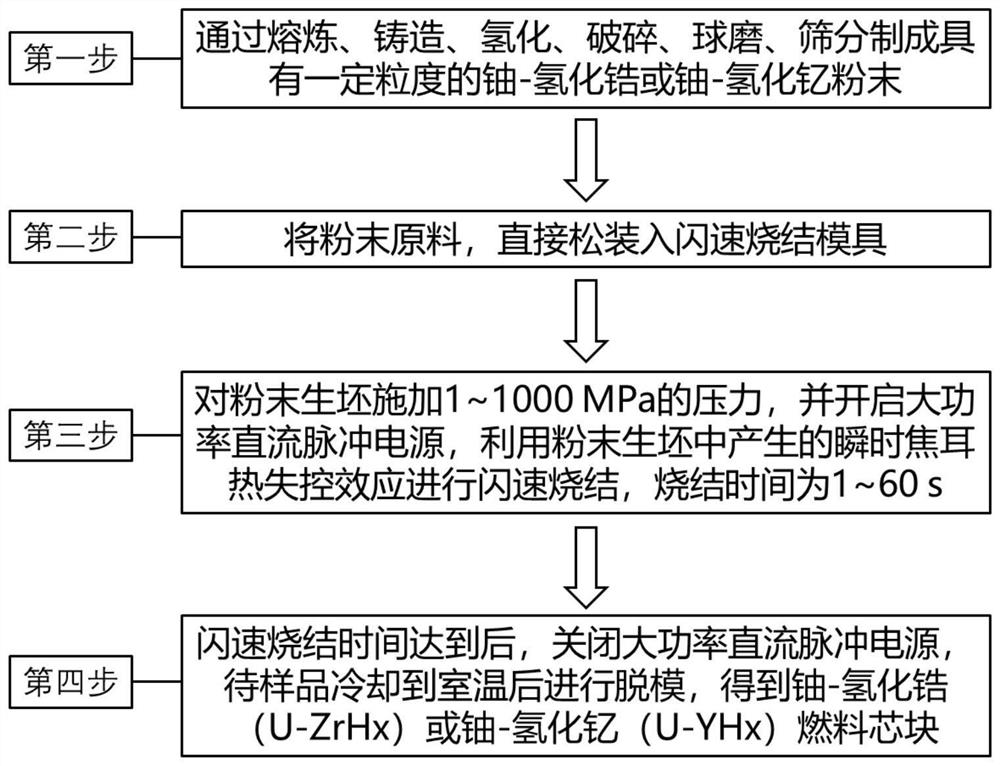

Method used

Image

Examples

Embodiment 1

[0035] This embodiment is uranium-zirconium hydride (U-ZrH x ) is prepared by flash sintering of fuel pellets, wherein the mass fraction of uranium 235 is 10%, and the design hydrogen zirconium ratio x is 1.43. First, uranium-zirconium alloy ingots are obtained by melting and casting according to the designed composition; then, the obtained ingots are subjected to appropriate hydrogenation treatment in a hydrogenation device to prepare uranium-zirconium hydride (U-ZrH x ) block fuel; then the obtained uranium-zirconium hydride block fuel is mechanically crushed, and further ball milled and sieved to make uranium-zirconium hydride powder with a certain particle size, which is used as a sintering raw material for standby; then weigh about 1g of powder raw material , and directly loosely load it into a flash sintering mold with an inner diameter of 10mm. After the powder raw material and electrodes are loaded, apply a pressure of 100MPa to the powder green body, and set the outpu...

Embodiment 2

[0037] This embodiment is uranium-zirconium hydride (U-ZrH x ) is prepared by flash sintering of fuel pellets, wherein the mass fraction of uranium 235 is 30%, and the design hydrogen zirconium ratio x is 1.57. First, uranium-zirconium alloy ingots are obtained by melting and casting according to the designed composition; then, the obtained ingots are subjected to appropriate hydrogenation treatment in a hydrogenation device to prepare uranium-zirconium hydride (U-ZrH x ) block fuel; then the obtained uranium-zirconium hydride block fuel is mechanically crushed, and further ball milled and sieved to make uranium-zirconium hydride powder with a certain particle size, which is used as a sintering raw material for standby; then weigh about 1g of powder raw material , and directly loosely load it into a flash sintering mold with an inner diameter of 10mm. After the powder raw materials and electrodes are loaded, apply a pressure of 250MPa to the powder green body, and set the outp...

Embodiment 3

[0039] This embodiment is uranium-zirconium hydride (U-ZrH x ) is prepared by flash sintering of fuel pellets, wherein the mass fraction of uranium 235 is 60%, and the design hydrogen zirconium ratio x is 1.71. First, uranium-zirconium alloy ingots are obtained by melting and casting according to the designed composition; then, the obtained ingots are subjected to appropriate hydrogenation treatment in a hydrogenation device to prepare uranium-zirconium hydride (U-ZrH x ) block fuel; then the obtained uranium-zirconium hydride block fuel is mechanically crushed, and further ball milled and sieved to make uranium-zirconium hydride powder with a certain particle size, which is used as a sintering raw material for standby; then weigh about 1g of powder raw material , and directly loosely load it into a flash sintering mold with an inner diameter of 10mm. After the powder raw materials and electrodes are loaded, apply a pressure of 500MPa to the powder green body, and set the outp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com