Anti-surge system and control method for screw conveyor

A screw conveyor and gushing prevention technology, which is applied in the direction of earth drilling, mining equipment, tunnels, etc., can solve the problem that the roadheader cannot continue to excavate the soil cabin, and achieve the effect of improving the tunnel construction environment, solving gushing, and preventing mud from settling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

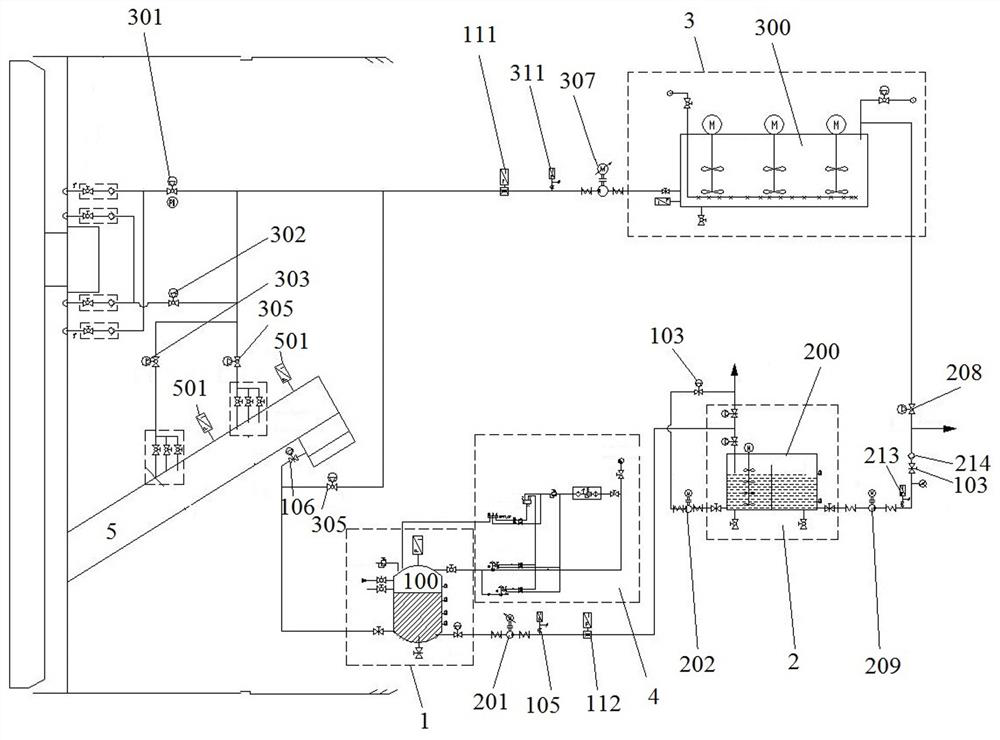

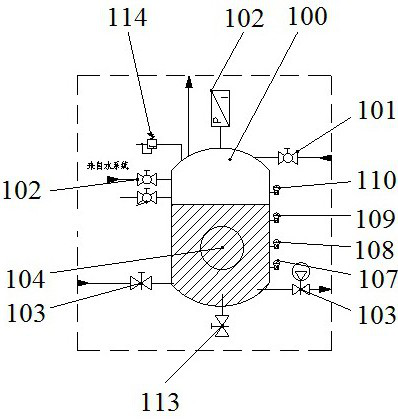

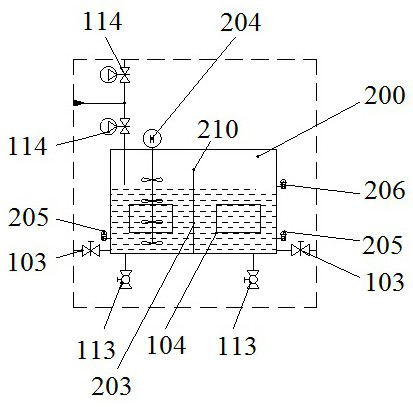

[0037] Embodiment 1, a kind of screw conveyor anti-splash system, such as figure 1 As shown, it is connected to the screw conveyor 5, and two first pressure sensors 501 are arranged at intervals in the axial direction of the screw conveyor 5 for detecting the pressure near the slag inlet and the slag outlet of the screw conveyor 5 . The screw conveyor 5 is provided with a grouting port and a grouting port, and a pressure holding unit 1, a slurry separation unit 2 and a mud improvement unit 3 are sequentially connected between the grouting port and the grouting port, and the pressure holding unit 1 includes a A second pressure sensor 102 is provided in the pressure holding tank 100 connected to the slurry discharge port, and the second pressure sensor 102 is connected to the pressure adjustment unit 4; the slurry separation unit 2 includes a slurry separation tank 200 connected to the pressure holding tank 100 , the mud tank of the slurry separation tank 200 is connected with t...

Embodiment 2

[0049] Embodiment 2, a control method for the anti-splashing system of a screw conveyor. During the tunneling process of the roadheader, when the screw conveyor 5 spews, the rear gate of the screw conveyor 5 is quickly closed, the propulsion is stopped, and the first control valve is opened. 301, the second control valve 302, start the slurry inlet pump 307, inject slurry into the soil cabin and the screw conveyor 5, keep the cutter head and the screw conveyor 5 rotating at a low speed, so that the particles and slurry in the muck are integrated and formed better ground fluidity; when the pressure measured by the first pressure sensor 501 at the front of the screw conveyor 5 is equivalent to the pressure of the first pressure sensor 501 in the middle, the first control valve 301 and the second control valve 302 are closed.

[0050] Start the pressure holding unit 1, set the pressure in the pressure holding tank 100 slightly lower than the pressure at the rear of the screw conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com