High-specific-characteristic lithium ion capacitor and preparation method thereof

A technology of capacitors and lithium ions, which is applied in the field of high-specificity lithium-ion capacitors and its preparation, can solve problems such as unreasonable collocation or ratio, difficulty in meeting the energy density and high-power discharge capacity of high-specification capacitors, and achieve The effect of high energy density, high specific capacitance, and high power discharge capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A preparation method for a high specific characteristic lithium ion capacitor, comprising the steps of:

[0042] (1) Preparation of negative electrode sheet: Mix activated carbon, graphene-based Fe3O4 composite material, lithium titanate, carbon nanotubes, polytetrafluoroethylene, and N-dimethylpyrrolidone for 2-3 hours to obtain a uniform viscous shape The negative electrode active slurry was coated on the current collector with a squeegee, dried in a vacuum oven at 80-100°C for 48 hours, and cut according to the required size to obtain the negative electrode sheet;

[0043] (2) Production of positive electrode sheet: mix lithium cobalt oxide, graphene-based manganese dioxide composite material, NCM811, graphene, activated carbon, carbon nanotubes, polytetrafluoroethylene, and N-dimethylpyrrolidone for 2-3 hours to obtain a uniform The viscous positive electrode active slurry is coated on the current collector with a squeegee, dried in a vacuum drying oven at 80-100°C ...

Embodiment 2

[0050] A preparation method for a high specific characteristic lithium ion capacitor, comprising the steps of:

[0051] (1) Negative plate production: Mix graphene-based Fe3O4 composite material, activated carbon, lithium titanate, carbon nanotubes, polytetrafluoroethylene, and N-dimethylpyrrolidone for 2-3 hours to obtain a uniform viscous shape The negative electrode active slurry was coated on the current collector with a squeegee, dried in a vacuum oven at 80-100°C for 48 hours, and cut according to the required size to obtain the negative electrode sheet;

[0052] (2) Production of positive electrode sheet: mix lithium cobalt oxide, graphene-based manganese dioxide composite material, NCM811, graphene, activated carbon, carbon nanotubes, polytetrafluoroethylene, and N-dimethylpyrrolidone for 2-3 hours to obtain a uniform The viscous positive electrode active slurry is coated on the current collector with a squeegee, dried in a vacuum drying oven at 80-100°C for 48 hours, ...

Embodiment 3

[0059] A preparation method for a high specific characteristic lithium ion capacitor, comprising the steps of:

[0060] (1) Negative plate production: Mix graphene-based Fe3O4 composite material, activated carbon, lithium titanate, carbon nanotubes, polytetrafluoroethylene, and N-dimethylpyrrolidone for 2-3 hours to obtain a uniform viscous shape The negative electrode active slurry was coated on the current collector with a squeegee, dried in a vacuum oven at 80-100°C for 48 hours, and cut according to the required size to obtain the negative electrode sheet;

[0061] (2) Production of positive electrode sheet: mix lithium cobalt oxide, graphene-based manganese dioxide composite material, NCM811, graphene, activated carbon, carbon nanotubes, polytetrafluoroethylene, and N-dimethylpyrrolidone for 2-3 hours to obtain a uniform The viscous positive electrode active slurry is coated on the current collector with a squeegee, dried in a vacuum drying oven at 80-100°C for 48 hours, ...

PUM

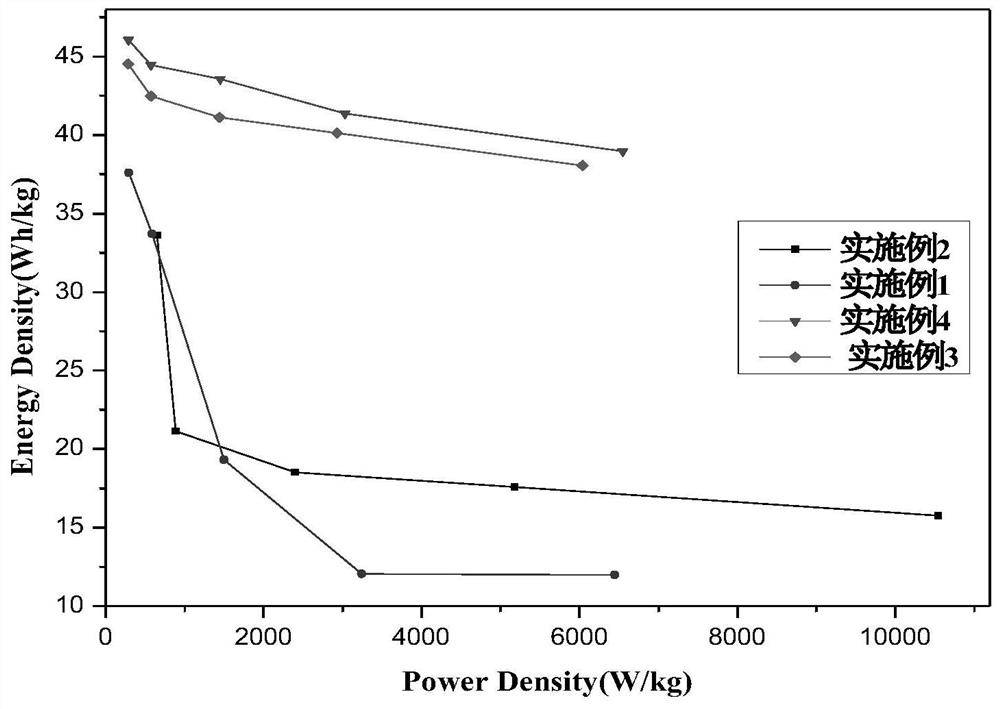

| Property | Measurement | Unit |

|---|---|---|

| Power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com