A kind of manufacturing method of micro thermoelectric device

A technology for thermoelectric devices and manufacturing methods, which is applied in the manufacture/processing of thermoelectric devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., and can solve the problems of metallization layer pollution, unfavorable welding process, and inaccurate arrangement of thermoelectric particles, etc. , to achieve high-precision assembly and welding, improve performance consistency, and ensure contact accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for designing a pendulum mold tool for manufacturing a micro thermoelectric device, comprising the following steps:

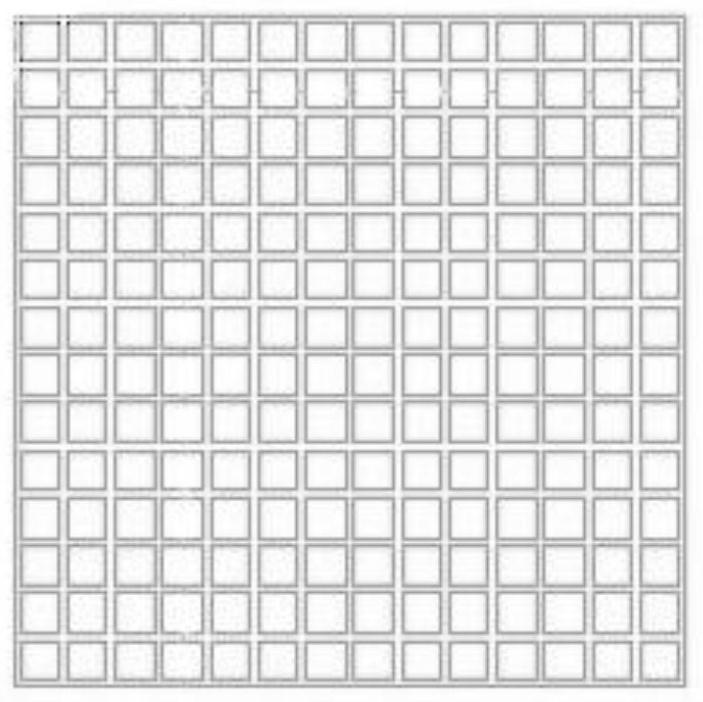

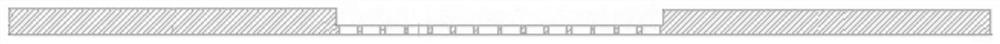

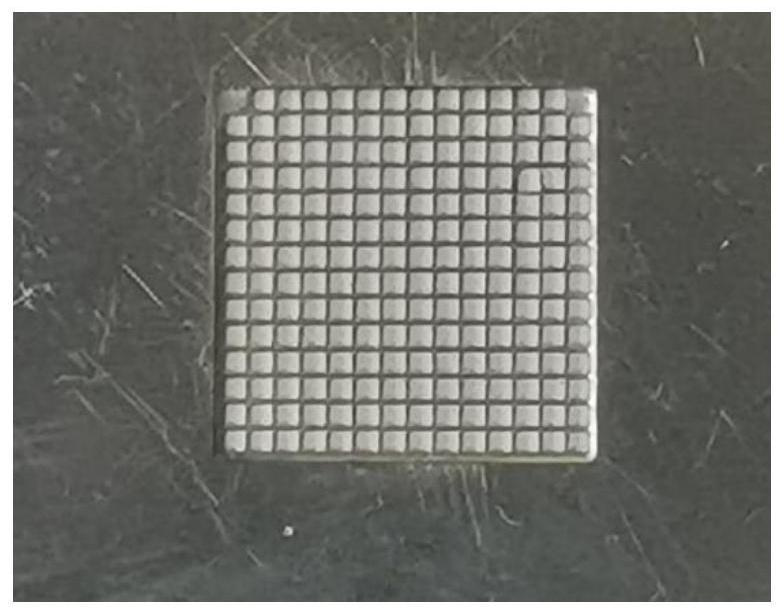

[0033] 1) The size of the micro thermoelectric device to be fabricated in this example is 8×8mm 2 , a total of 97 pairs of micro thermoelectric particles; design the steel mold drawings according to the requirements of the electrode substrate of the micro thermoelectric device, such as figure 1 and figure 2 shown;

[0034] 2) Use a continuous laser to process a steel mold according to the drawing described in step 1); the steel mold includes a limit plate and an outer frame arranged around the limit plate, and the top surface of the limit plate and the inner side of the outer frame form a concave The groove is used to accommodate the electrode substrate, and a plurality of square through holes are opened on the limiting plate to limit the position of the thermoelectric particles; The groove depth is 0.35mm; the inner diameter of each square ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com