A method for controllable growth of metallic single-walled carbon nanotubes through substrate design

A single-wall carbon nanotube, carbon nanotube technology, applied in the direction of carbon nanotubes, nanocarbons, non-metallic elements, etc., can solve the problems of poor high temperature thermal stability, poor uniformity of carbon nanotube diameter, poor repeatability, etc. Effects of large growth rate differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

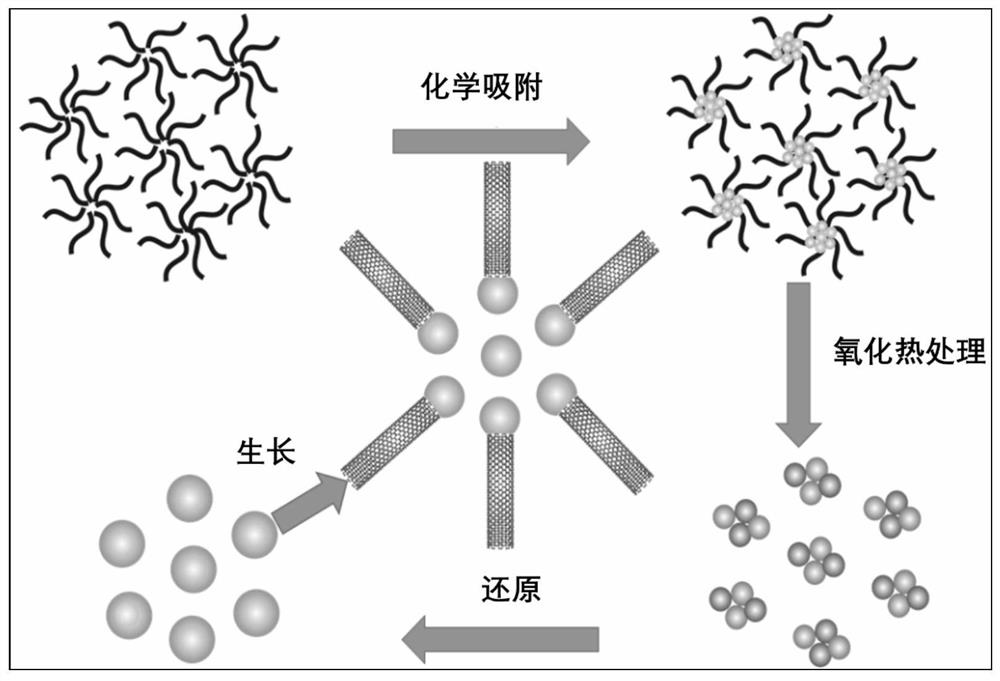

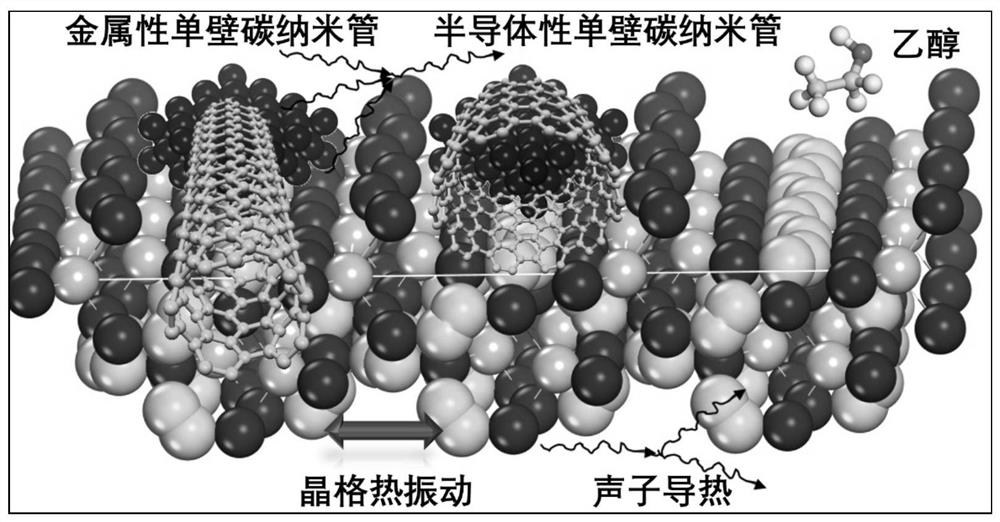

Method used

Image

Examples

Embodiment 1

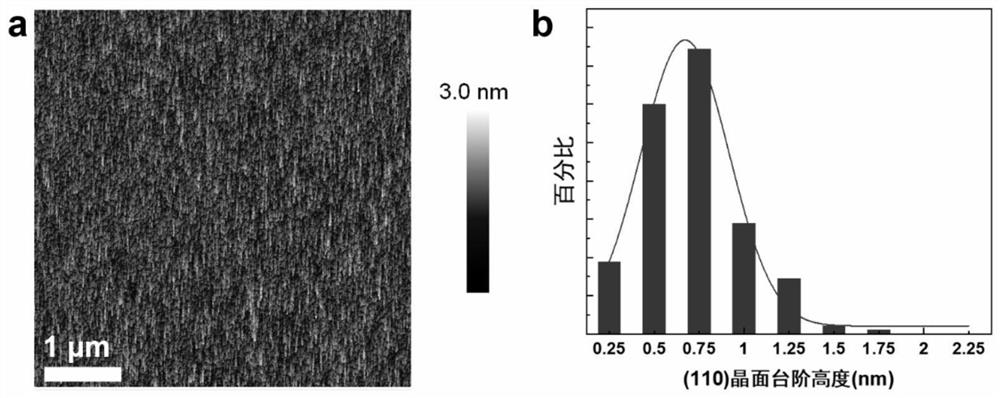

[0046] In this embodiment, the spinel containing the (110) crystal plane treated in the above step (1) is heat-treated at 450° C. for 3 hours in the air.

[0047] Adopt step (2) to support the cobalt particles on the spinel (110) surface and carry out oxidation and reduction treatment, the oxidation conditions are 450 ℃, 3min; the reduction conditions are 765 ℃, 90sccmAr+4sccmH 2 , 3min. The morphology of the cobalt particles prepared in step (2) was characterized by transmission electron microscopy ( Figure 5 a), the particle size was found to be small and uniform; the diameter distribution of cobalt particles under the transmission electron microscope ( Figure 5 b) shows that the particle size is mainly concentrated in 1-3 nm; Figure 5 Scanning transmission electron imaging of c further demonstrates the compositional homogeneity of the cobalt particles. The surface of the substrate was sputtered by X-ray photoelectron spectroscopy and secondary ion mass spectrometry, r...

Embodiment 2

[0050] In this embodiment, step (1) is the same as step (1) of the embodiment, and the temperature and time of heat treatment in air are 500° C. and 2h, respectively.

[0051] Step (2) is the same as the step (2) of the embodiment, the oxidation temperature and time are respectively 600 ℃, 1min, the reduction temperature and time are respectively 850 ℃, 1min, and the reducing atmosphere is 100sccmAr+3sccmH 2 . The size and morphology of the Co particles were characterized by transmission electron microscopy. The lattice fringe spacing of the 50 particles is centered at 0.2-0.22 nm, indicating that the substrate has a significant effect of stabilizing the catalyst structure.

[0052]Step (3) is the same as the step (3) of the embodiment, the growth temperature and time of the single-walled carbon nanotubes are respectively 775 ° C and 7min, the argon flow rate loaded with ethanol is 17sccm, the hydrogen flow rate is 1sccm, and the argon carrier gas flow rate is 90sccm. Scann...

Embodiment 3

[0054] In this embodiment, step (1) is the same as step (1) of the embodiment, and the temperature and time of heat treatment in air are 400° C. and 3h, respectively.

[0055] Step (2) is the same as the step (2) of the embodiment, the oxidation temperature and time are respectively 400 ℃, 5min, the reduction temperature and time are respectively 700 ℃, 5min, and the reducing atmosphere is 80sccmAr+5sccmH 2 . The size and morphology of the Co particles were characterized by transmission electron microscopy. The lattice fringe spacing of the 50 particles is centered at 0.2-0.22 nm, indicating that the substrate has a significant effect of stabilizing the catalyst structure.

[0056] Step (3) is the same as the step (3) of the embodiment, the growth temperature and time of the single-walled carbon nanotubes are respectively 765 ° C and 10min, the argon flow rate loaded with ethanol is 20sccm, the hydrogen flow rate is 3sccm, and the argon carrier gas flow rate is 100sccm. Sca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com