Supported nano-alloy catalyst and universal preparation method

A nano-alloy and catalyst technology, which is applied in the field of nano-alloy catalyst preparation, can solve the problems of reducing platinum utilization, burying active sites, high-temperature agglomeration of nanoparticles, etc., and achieves the effects of small size, uniform distribution and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

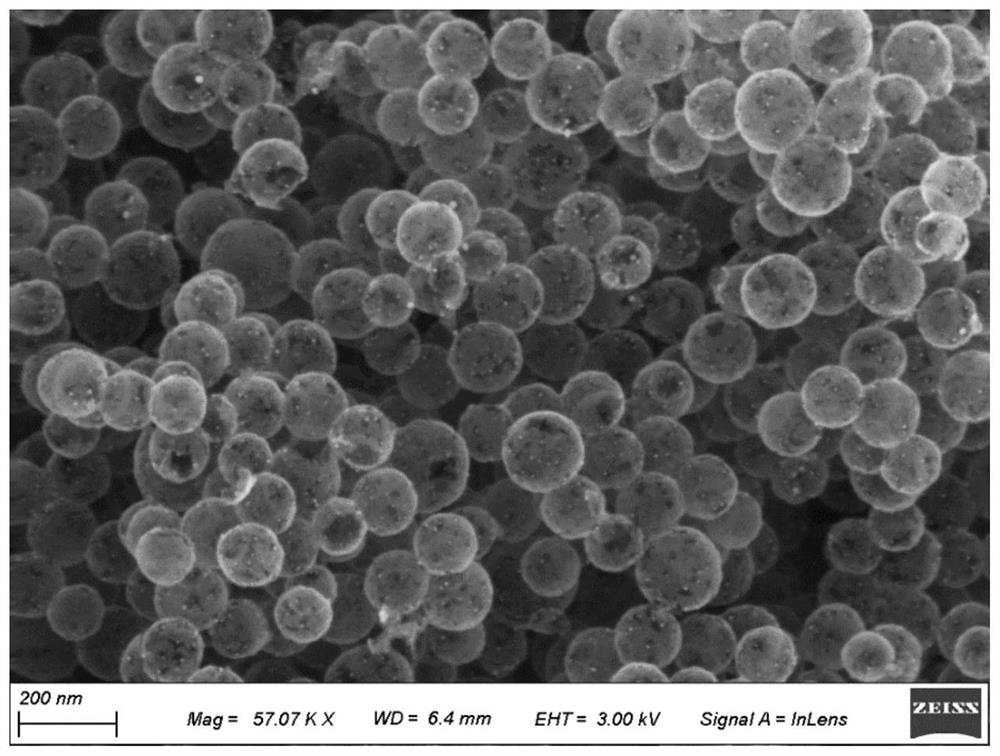

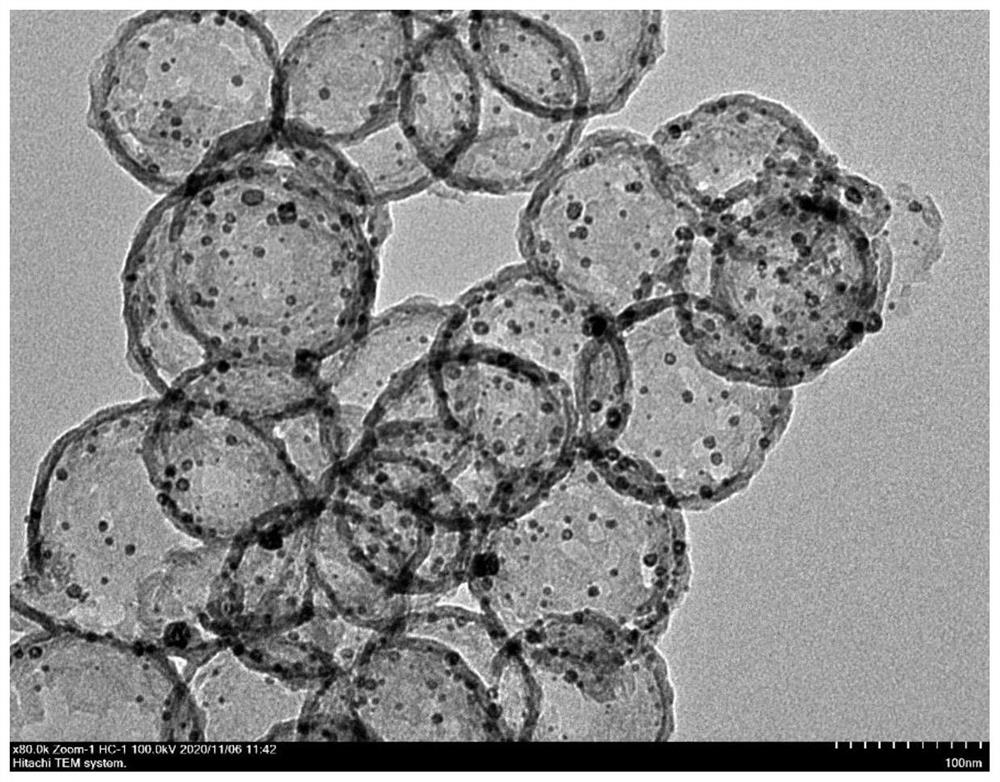

[0035] Step 1: 500mg of silica microspheres were dispersed in 40mL of water, 1g of cobalt nitrate was added for 20min, and then the reaction was stirred at 80 °C for 16h, centrifuged, separated, vacuum dried after the reaction, and the resulting product was roasted for 30 min at 400 °C under an air atmosphere to obtain the precursor.

[0036] Step 2: Disperse the precursor in a solution containing 20 mL of water and 20 mL of ethanol, Add 0.0386 mmol chloroplatinic acid containing 10 mL volume ratio of 1:1 water and ethanol mixed solution stirred reaction for 6 h, and then weigh 1.0 mmol dopamine dissolved in 30 mL volume ratio of 1:1 water and ethanol mixed solution was added to the stirring reaction for 5 h, and then added 8 mL volume ratio of 2 mL ammonia water volume ratio of 1:1 water and ethanol mixed solution, continue to stir the reaction at room temperature for 12 h, after the reaction is over, the product is put into the tubular furnace under a nitrogen atmosphere at 5 °C...

Embodiment 2

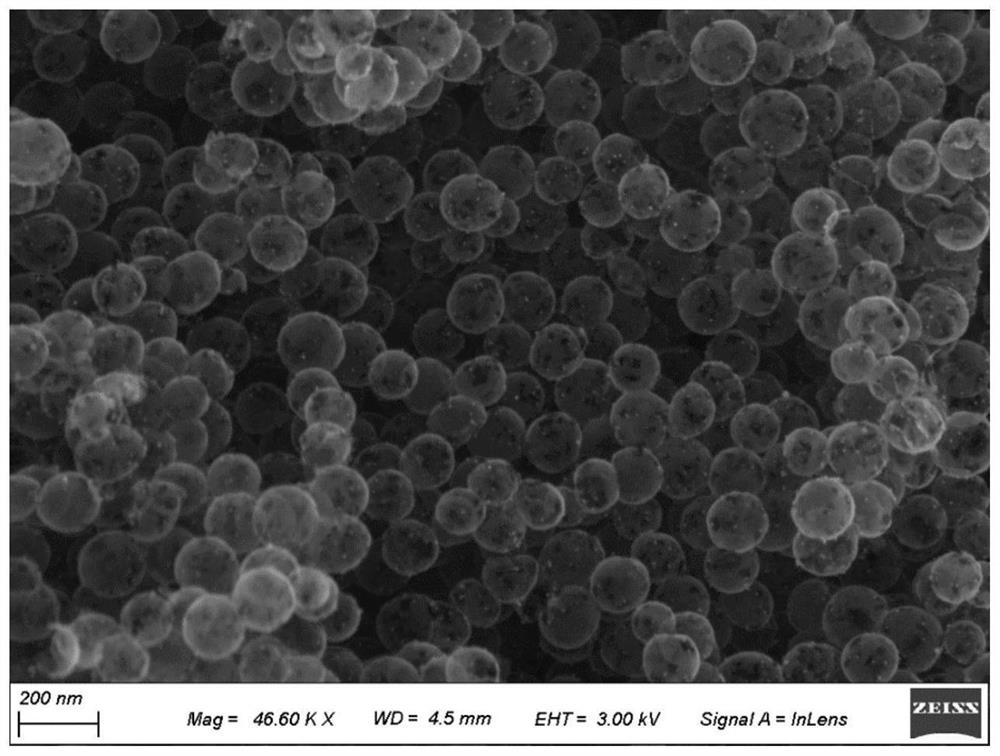

[0038]Step 1: 500mg of silica microspheres were dispersed in 40mL of water, 1g of nickel nitrate was added for ultrasonic dispersion for 20min, and then the reaction was stirred at 80 °C for 14h, centrifuged, separated, vacuum dried after the reaction, and the resulting product was roasted at 400 °C under an air atmosphere for 30 min to obtain the precursor.

[0039] Step 2: Disperse the precursor in a solution containing 20 mL of water and 20 mL of ethanol, Add 0.0386 mmol chloroplatinic acid containing 10 mL volume ratio of 1:1 water and ethanol mixed solution stirred reaction for 6h, and then weigh 1.2 mmol dopamine dissolved in 30 mL volume ratio of 1:1 water and ethanol mixed solution added to the stirring reaction for 3 h, and then add 8 mL of ammonia containing 2 mL of water volume ratio of 1:1 water and ethanol mixed solution, continue to stir the reaction at room temperature for 12 h, after the reaction is over, the product is put into the tubular furnace under a nitrogen...

Embodiment 3

[0041] Step 1: 500mg of silica microspheres were dispersed in 40mL of water, 1g of iron nitrate was added to the ultrasonic dispersion for 20min, and then the reaction was stirred at 80 °C for 12h, centrifuged, separated and vacuum dried after the reaction, and the resulting product was roasted for 30 min at 400 °C under an air atmosphere to obtain the precursor.

[0042] Step 2: Disperse the precursor in a solution containing 20 mL of water and 20 mL of ethanol, Add 0.0386 mmol chloroplatinic acid containing 10 mL volume ratio of 1:1 water and ethanol mixed solution stirred reaction for 6 h, and then weigh 1.5 mmol dopamine dissolved in 30 mL volume ratio of 1:1 water and ethanol mixed solution was added to the stirring reaction for 3 h, and then added 8 mL of ammonia water volume ratio of 1:1 water and ethanol mixed solution, continue to stir the reaction at room temperature for 12 h, after the reaction is over, the product is put into the tubular furnace under a nitrogen atmosp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com