A preparation method of narrow diameter distribution, high-purity metallic single-walled carbon nanotubes

A technology of single-walled carbon nanotubes and diameter distribution, applied in the direction of single-walled carbon nanotubes, carbon nanotubes, nanocarbons, etc., can solve the problems of high-temperature instability and easy aggregation of metal nanoparticles, and wide diameter distribution of grown carbon nanotubes. , to achieve the effect of uniform size, narrow diameter distribution and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

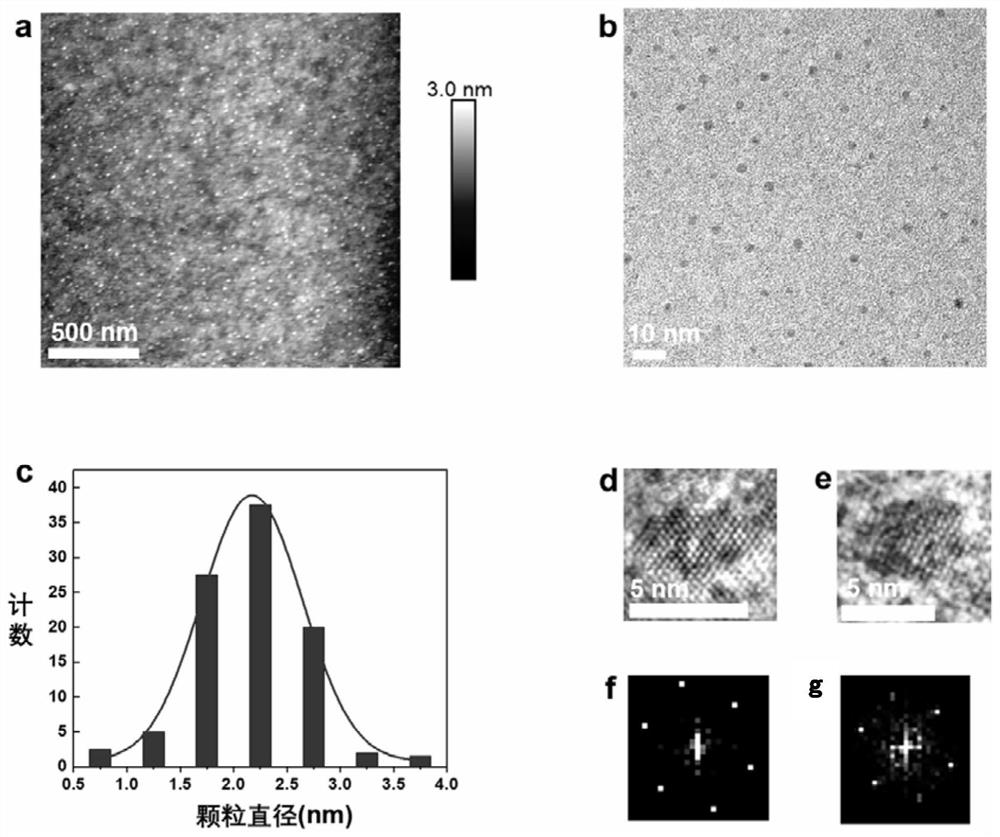

[0044] In this embodiment, the preparation and characterization of narrow diameter distribution, high-purity metallic single-walled carbon nanotubes are as follows:

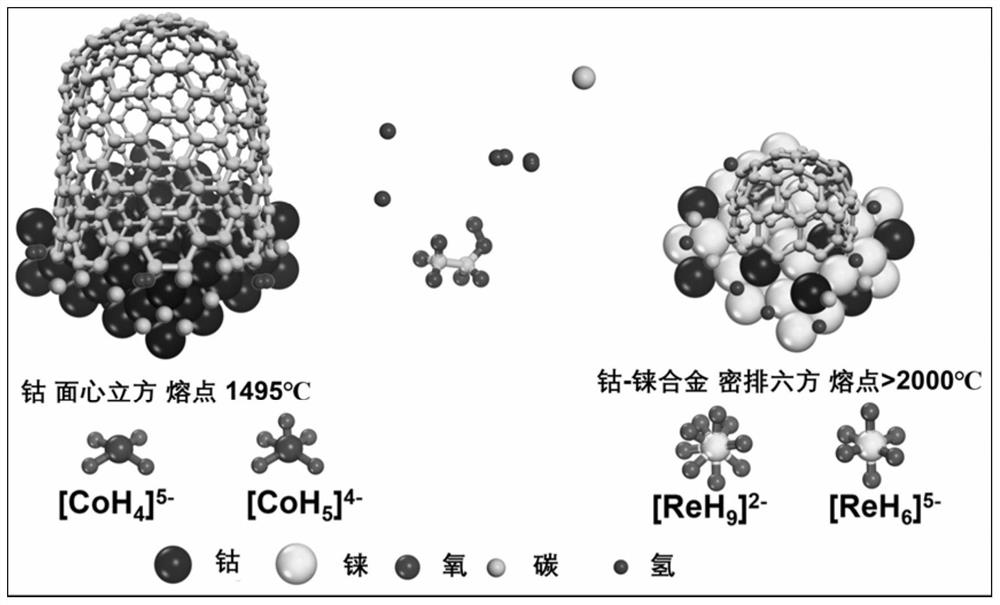

[0045] (1) CoRe x Preparation of bimetallic catalysts:

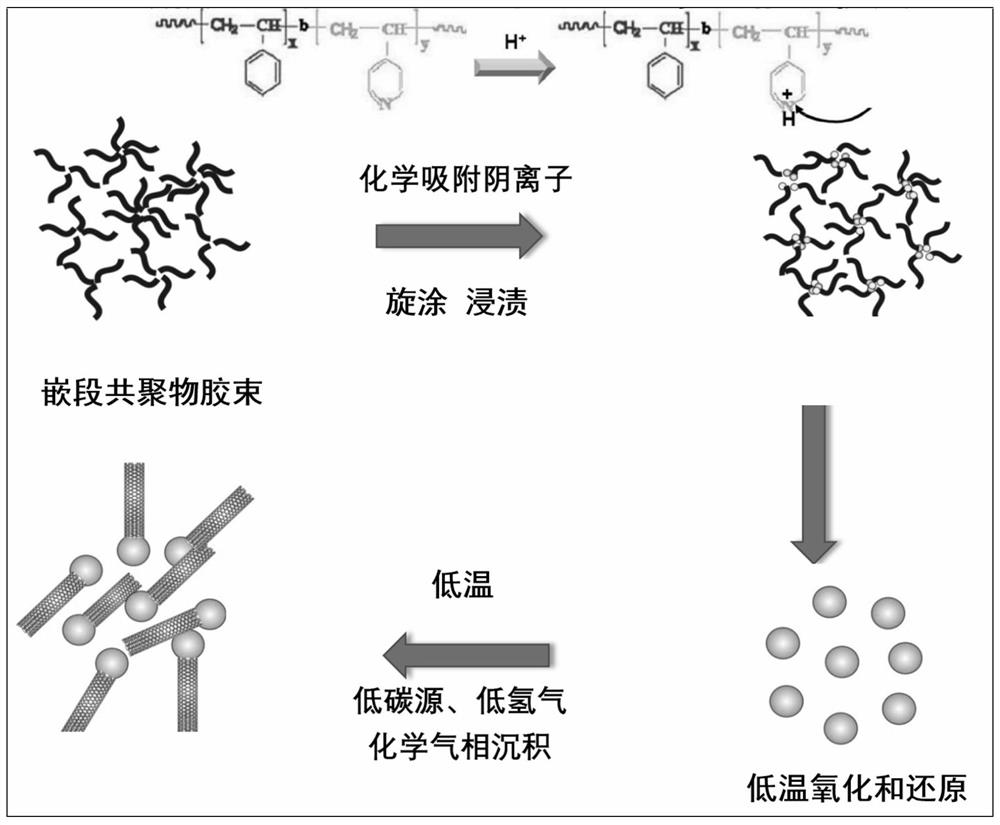

[0046] The 10mm×10mm silicon wafer was soaked in piranha solution for 15min for cleaning treatment, washed with deionized water, and then treated with oxygen plasma with a power of 32W. The concentration of 0.01 ~ 0.25wt% polystyrene-b-poly (4-vinylpyridine) block copolymer (PS50000-b-P4VP13000) in toluene and tetrahydrofuran solution (the mass ratio of toluene and tetrahydrofuran 3:1), Spin coating on the surface of the hydrophilic treated silicon wafer at a rotational speed of 2000-7000 rpm to form a block copolymer micelle film, and the block copolymer micelle height is 6-15nm. The silicon wafer is then immersed in a hydrochloric acid solution with a solvent of 0.01-1M (mol / L), wherein the solute is a bimetallic catalyst precursor salt (x mM (mmol / L) N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com