Coupling modified CNF/PCL composite material and application thereof

A composite material and coupling technology, which is applied in the field of coupling modified CNF/PCL composite materials, can solve the problems of poor dispersion of nanocellulose, easy agglomeration, complex preparation process, etc., to achieve improved homogeneity, low production cost, The effect of simple preparation process

Pending Publication Date: 2020-10-09

NANNING UNIV

View PDF9 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] The above-mentioned patent silk directly uses nanocellulose to aggregate lactone modification, but the dispersion of nanocellulose in the polymer is poor, and it is easy to agglomerate during high temperature reaction, and the preparation process is complicated.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0029] 1. Main raw materials and reagents

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

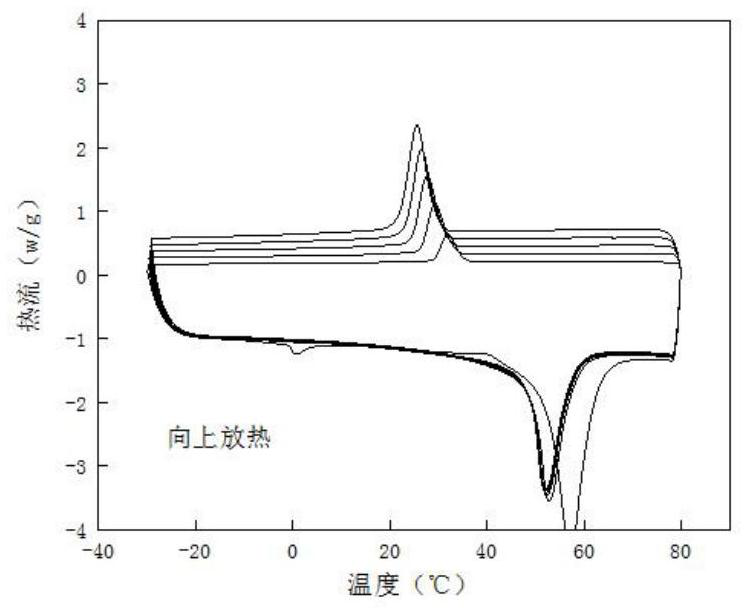

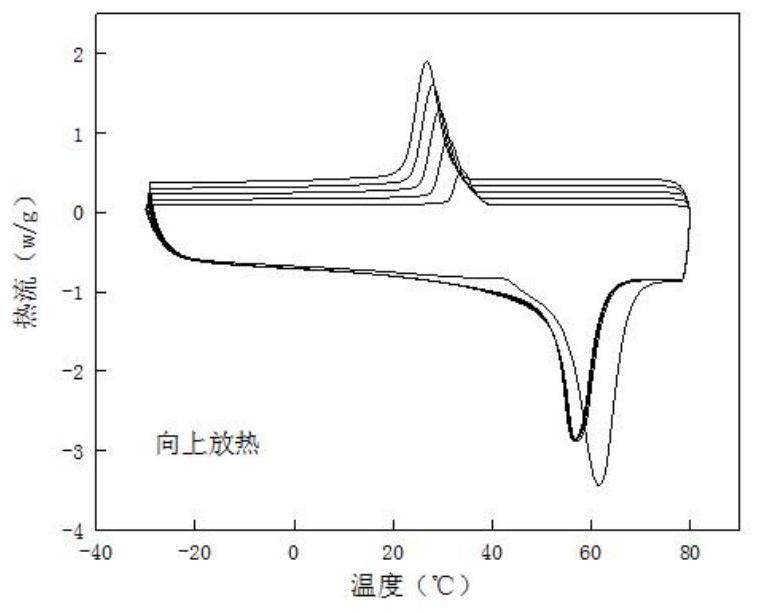

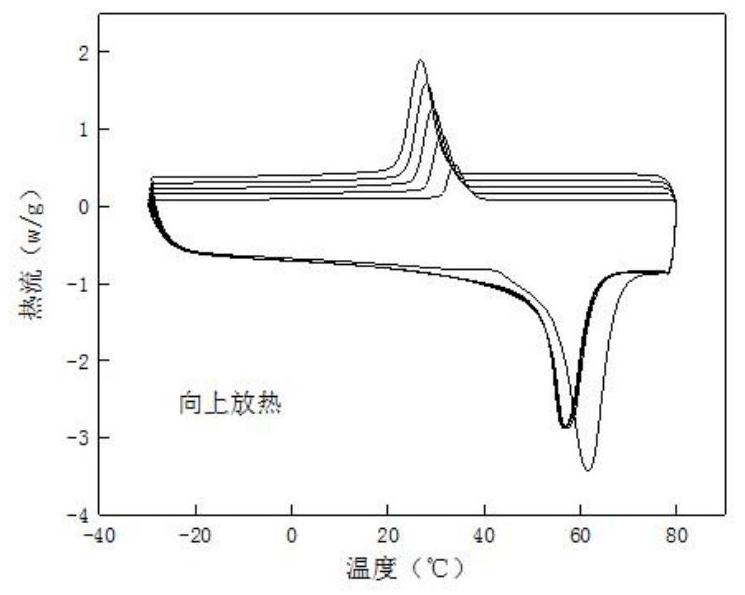

The invention relates to a coupling modified CNF / PCL composite material and application thereof. According to the composite material, coupling modified cotton nanocellulose is adopted to reinforce polycaprolactone. The preparation method of the coupling modified cotton nanocellulose comprises the following steps: ultrasonically dispersing the cotton nanocellulose into a dichloromethane solution toprepare a suspension; centrifugally separating the suspension, washing the centrifugate with absolute ethyl alcohol, and continuously centrifuging to remove all water to obtain CNF slurry; and addingthe NCF pulp into absolute ethyl alcohol, adding a silane coupling agent, stirring, standing, removing the absolute ethyl alcohol, and drying to obtain the coupling modified cotton nanocellulose. Thepolycaprolactone is treated by adopting the coupled modified cotton and linen nano-cellulose, the crystallinity of the polycaprolactone is reduced, the hydrophilicity of the polycaprolactone is improved, the problems of poor water solubility, poor hydrophilicity and low melting point of the polycaprolactone are solved, the influence on the thermal stability, crystallization effect and tensile strength of the polycaprolactone is small, and the material can be used for preparing biomedical materials.

Description

technical field [0001] The invention belongs to the technical field of biological composite materials, in particular to a coupling modified CNF / PCL composite material and its application. Background technique [0002] With the improvement of national education, people gradually realize the importance of protecting the environment, so people turn their attention from toxic and refractory polymer materials to pollution-free, natural and organic polymer materials, and through modification to obtain ideal high-quality composite materials. However, non-renewable resources are limited after all. For the long-term future, we must use natural resources to meet urgent needs. Natural plant fibers are all in nature, with the characteristics of no pollution, green and environmental protection. Compared with natural fibers, natural fibers have uneven length and fineness; good melting resistance and hygroscopicity; good antistatic properties, etc. features. [0003] Polycaprolactone is...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L67/04C08L1/02C08J5/18C08B15/00

CPCC08L67/04C08J5/18C08B15/00C08L2201/08C08L2205/06C08L2203/02C08L2312/00C08J2367/04C08J2401/02C08L1/02

Inventor 李仁焕庞锦英莫尚霖孙英云

Owner NANNING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com