Preparation method of metallic single-walled carbon nanotube with narrow diameter distribution and high purity

A technology of single-walled carbon nanotubes and diameter distribution, applied in the direction of single-walled carbon nanotubes, carbon nanotubes, nanocarbons, etc., can solve the problems of wide distribution of diameters of growing carbon nanotubes, unstable and easy aggregation of metal nanoparticles at high temperatures, etc. , to achieve the effects of controllable composition and structure, uniform and stable size, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

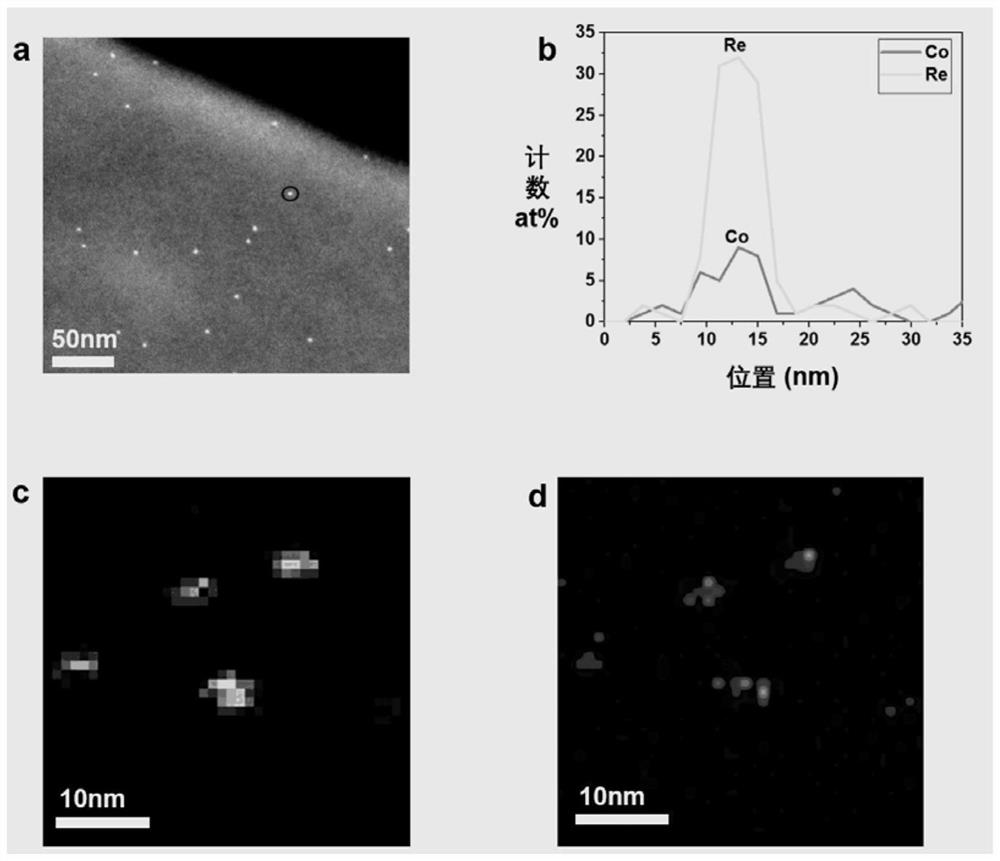

[0044] In this example, the preparation and characterization of narrow diameter distribution and high-purity metallic single-walled carbon nanotubes are as follows:

[0045] (1)CoRe x Preparation of bimetallic catalysts:

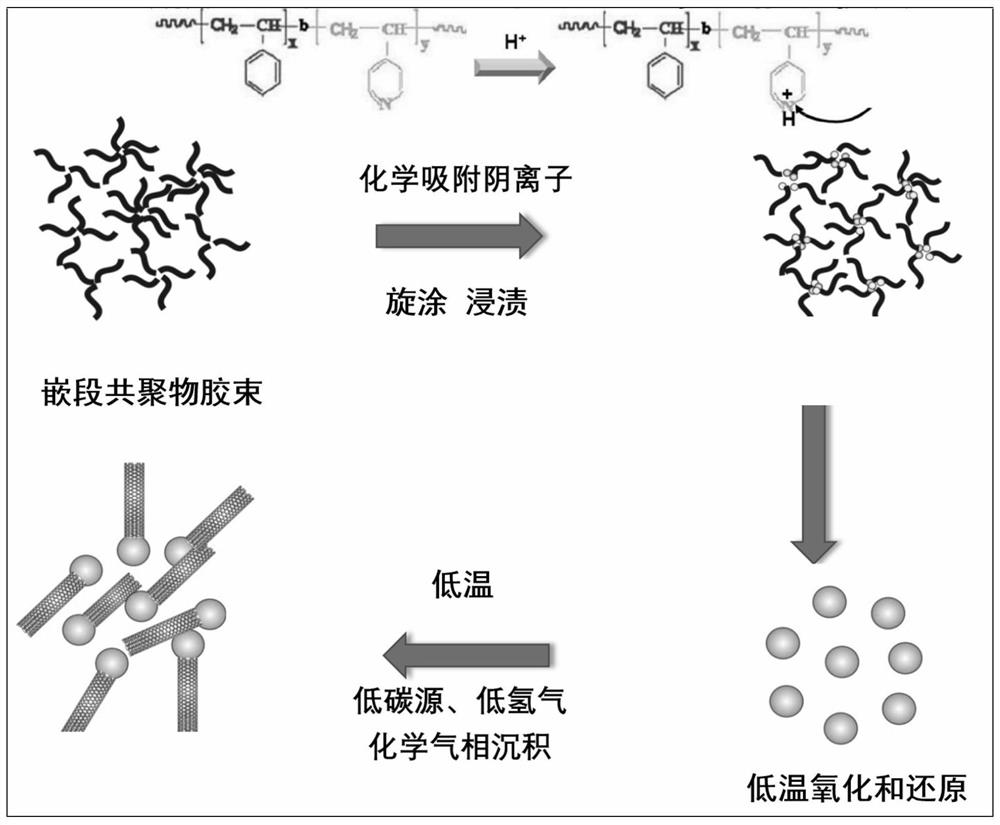

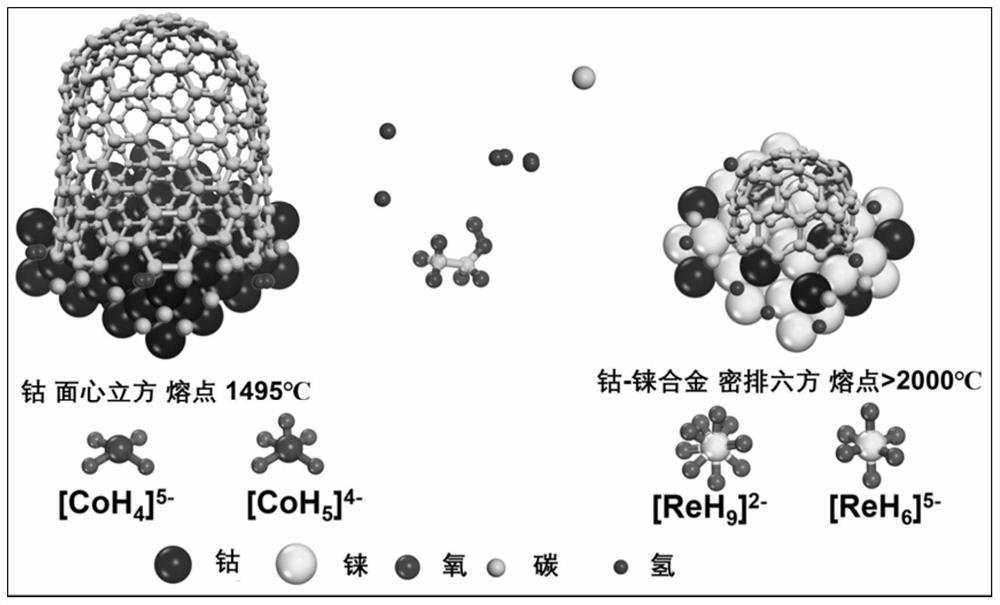

[0046] Soak a 10mm×10mm silicon wafer in piranha solution for 15 minutes for cleaning, wash it with deionized water, and treat it with oxygen plasma with a power of 32W. The concentration is 0.01~0.25wt% polystyrene-b-poly(4-vinylpyridine) block copolymer (PS50000-b-P4VP13000) in toluene and tetrahydrofuran solution (the mass ratio of toluene to tetrahydrofuran is 3:1), The method is spin-coated on the surface of the silicon chip after hydrophilic treatment at a rotational speed of 2000-7000rpm to form a block copolymer micelle film, and the height of the block copolymer micelle is 6-15nm. Then immerse the silicon chip in a hydrochloric acid solution with a solvent of 0.01-1M (mol / L), wherein the solute is a bimetallic catalyst precursor salt (x mM (mmol / L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com