Enzymatic extraction process of fatty acid

A technology for enzymatic extraction of fatty acids, applied in the field of enzymatic extraction of fatty acids, can solve the problems of low yield of fatty acids, instability of gossypol, etc., and achieve the effect of increasing the yield of fatty acids, increasing the yield, and mild reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

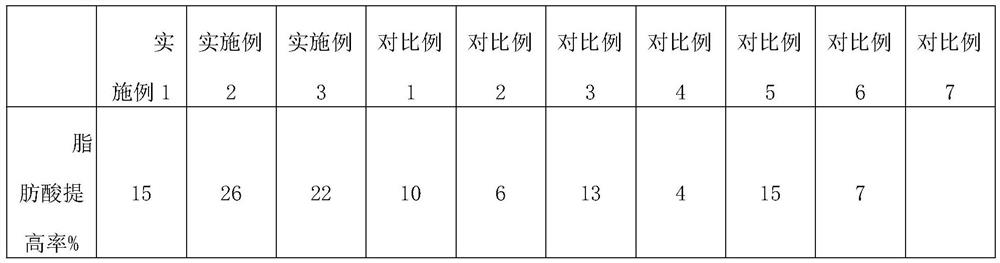

Examples

Embodiment 1

[0043] A kind of enzymatic extraction process of fatty acid, comprises the following steps:

[0044] 1) Add 300g of soapstock into the container, and add 600g of water and stir evenly to obtain the first mixture;

[0045] 2) Adjust the pH of the first mixture to 4 by using 10% acetic acid solution;

[0046] 3) Add 0.15g compound enzyme to the first mixture, the compound enzyme comprises 40wt% acid lipase, 40wt% neutral lipase and 20wt% phospholipase A2, the temperature is controlled at 40°C, stirred for 24h to carry out the enzymolysis reaction, to obtain the second mixture;

[0047] 4) The temperature of the second mixture after the enzymolysis reaction in step 3) was raised to 80° C., and kept for 30 minutes;

[0048] 5) Add 5% NaCl as a settling agent to the second mixture treated in step 4), and naturally lower the temperature and settle for 24 hours;

[0049] 6) The second mixture after sedimentation is subjected to oil-water separation to obtain fatty acid.

Embodiment 2

[0051] A kind of enzymatic extraction process of fatty acid, comprises the following steps:

[0052] 1) Add 400g of soapstock into the container, add 1200g of water and stir evenly to obtain the first mixture;

[0053] 2) Adjust the pH of the first mixture to 5 with 20% citric acid solution;

[0054]3) Add 0.4 g of compound enzyme to the first mixture, the compound enzyme includes 45wt% acid lipase, 36wt% neutral lipase and 19wt% phospholipase A2, control the temperature at 50°C, stir for 50h to carry out enzymolysis reaction, and obtain the second Two mixtures;

[0055] 4) The temperature of the second mixture after the enzymatic hydrolysis reaction in step 3) was raised to 85° C., and kept for 40 minutes;

[0056] 5) Add 10% NaCl as a settling agent to the second mixture treated in step 4), and naturally cool down and settle for 48 hours;

[0057] 6) The second mixture after sedimentation is subjected to oil-water separation to obtain fatty acid.

Embodiment 3

[0059] A kind of enzymatic extraction process of fatty acid, comprises the following steps:

[0060] 1) Add 500g of oil base into the container, and add 2500g of water and stir evenly to obtain the first mixture;

[0061] 2) Adjusting the pH of the first mixture to 6 with 20% citric acid solution;

[0062] 3) Add 2.5 g of compound enzyme to the first mixture, the compound enzyme includes 50wt% acid lipase, 40wt% neutral lipase and 10wt% phospholipase A2, control the temperature at 60°C, stir for 72h to carry out enzymolysis reaction, and obtain the second Two mixtures;

[0063] 4) heating the second mixture after the enzymatic hydrolysis reaction in step 3) to 90° C., and keeping it warm for 60 minutes;

[0064] 5) Add 20% NaCl as a settling agent to the second mixture treated in step 4), and naturally lower the temperature and settle for 72 hours;

[0065] 6) The second mixture after sedimentation is subjected to oil-water separation to obtain fatty acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com