A New Drilling Method Shaft Tunneling Machine

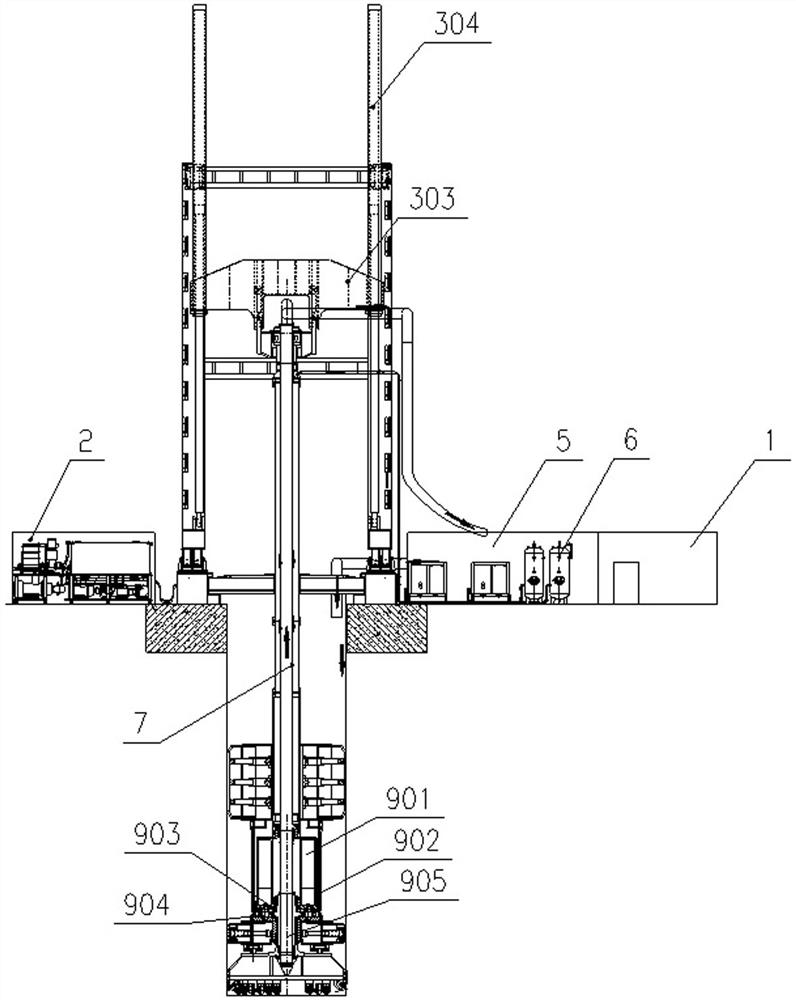

A technology of drilling method and roadheader, which is applied in the field of new type drilling method shaft roadheader, can solve problems such as unsuitable control of verticality, too long drill pipe, cutterhead, tool drill pipe damage, etc., so as to improve the rock breaking ability of the cutterhead and Efficiency, improved stability and pressure, and the effect of precise drilling construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

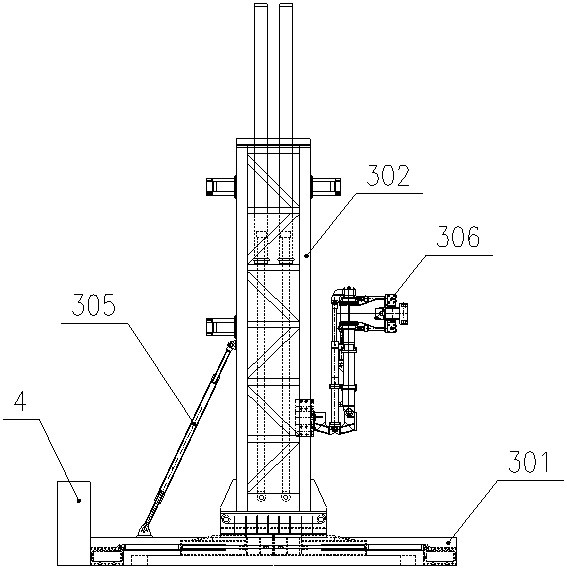

[0040] Embodiment 2: as figure 2 As shown, a new type of drilling method shaft boring machine, the side of the main column 303 is fixed with a drill pipe assembling manipulator 306, the drill pipe assembling manipulator 306 is used for assembling the drill pipe, improves the automation of the drill pipe assembling, and reduces the labor force strength, shortening the working time; the foundation chassis 301 is flexibly connected with the main column 302 through the column tilting cylinder 305, and when the equipment goes out of the well, the main column 302 can be tilted at a certain angle under the action of the column tilting cylinder 305, so that Out of the wellhead, it is convenient for hoisting equipment to lift.

[0041] All the other structures are the same as in Example 1.

Embodiment 3

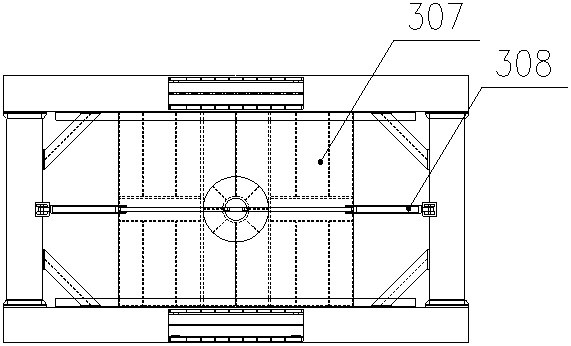

[0042] Embodiment 3: as Figure 4 As shown, a new type of shaft boring machine with drilling method, the upper part of the fixed slide box 801-3 is fixed with a cutter beam, and the cutter beam is sleeved on the drill pipe 7; Cutter 801-4, several cutters are set in parallel on the cutter beam, use the cutters to solve the problem that the equipment cannot be raised in the well due to the convergence of the soft soil layer during the construction process, when this situation occurs, the cutter can be used to cut and converge the wellbore, Make the equipment go up well smoothly.

[0043] All the other structures are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com