Method for preparing scald ointment by utilizing marine fish leftovers

A technology for scraps and scald ointment, which is applied in the directions of medical raw materials derived from fish feed, medical preparations with inactive ingredients, and medical preparations containing active ingredients, etc., can solve the problems of skin irritation, skin appearance, pigmentation and other problems , to prevent bacterial infection, good biocompatibility, and promote wound healing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

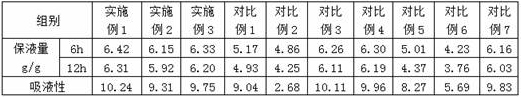

Examples

Embodiment 1

[0029] A kind of method utilizing sea fish leftovers to prepare scald ointment, it goes through the following process steps:

[0030] 1) Pretreatment of sea fish waste

[0031] a. Take the leftovers of marine fish, rinse them with distilled water, put them in a sterilizing pot, steam them at a temperature of 121°C and a pressure of 0.12 MPa for 18 minutes, take them out and cool them, crush them with a pulverizer and homogenize them, and adjust the concentration of the solids in the homogenate 70%;

[0032] b. Take the homogenate obtained in step a, add 2% collagenase and 4% lactobacillus by weight to the homogenate, grind at a temperature of 45°C for 130min, and perform ultrasonic treatment at the same time. The ultrasonic conditions are: ultrasonic frequency 12KHz, ultrasonic power 1.3W / cm 2 After grinding, add sterile water of equal quality, filter out solids, and prepare a reserve liquid for sea fish offal;

[0033] 2) Kelp pretreatment

[0034] Put the kelp in a pres...

Embodiment 2

[0042] A kind of method utilizing sea fish leftovers to prepare scald ointment, it goes through the following process steps:

[0043] 1) Pretreatment of sea fish waste

[0044] a. Take the leftovers of sea fish, rinse them with distilled water, put them into a sterilizing pot, steam them at a temperature of 115°C and a pressure of 0.1MPa for 15 minutes, take them out and cool them, grind them with a pulverizer and homogenize them, and adjust the concentration of the solids in the homogenate 65%;

[0045] b. Take the homogenate obtained in step a, add 2% collagenase and 3% lactobacillus by weight to the homogenate, grind at a temperature of 35°C for 90 minutes, and perform ultrasonic treatment at the same time. The ultrasonic conditions are: ultrasonic frequency 11KHz, ultrasonic power 0.6W / cm 2 After grinding, add sterile water of equal quality, filter out solids, and prepare a reserve liquid for sea fish offal;

[0046] 2) Kelp pretreatment

[0047] Put the kelp in a pre...

Embodiment 3

[0055] A kind of method utilizing sea fish leftovers to prepare scald ointment, it goes through the following process steps:

[0056] 1) Pretreatment of sea fish waste

[0057] a. Take the leftovers of marine fish, rinse them with distilled water, put them into a sterilizing pot, steam them at a temperature of 121°C and a pressure of 0.125 MPa for 20 minutes, take them out and cool them, crush them with a pulverizer and homogenize them, and adjust the concentration of the solids in the homogenate 80%;

[0058] b. Take the homogenate obtained in step a, add 2-3% collagenase and 3-5% lactobacillus by weight to the homogenate, grind at a temperature of 55°C for 150 minutes, and perform ultrasonic treatment at the same time. The ultrasonic conditions are: ultrasonic frequency 14KHz, ultrasonic Power 1.5W / cm 2 After grinding, add sterile water of equal quality, filter out solids, and prepare a reserve liquid for sea fish offal;

[0059] 2) Kelp pretreatment

[0060] Put the kel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com