Water-based paint resin film veneer solid wood composite floor with low VOCs release and preparation method thereof

A solid wood composite floor, resin film technology, applied in the direction of floor covering, wood layer products, chemical instruments and methods, etc., can solve the problems of poor wear resistance, increased production cost, affecting the performance of paint film, etc., to achieve low VOCs release, The effect of solving poor surface performance and improving decorative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

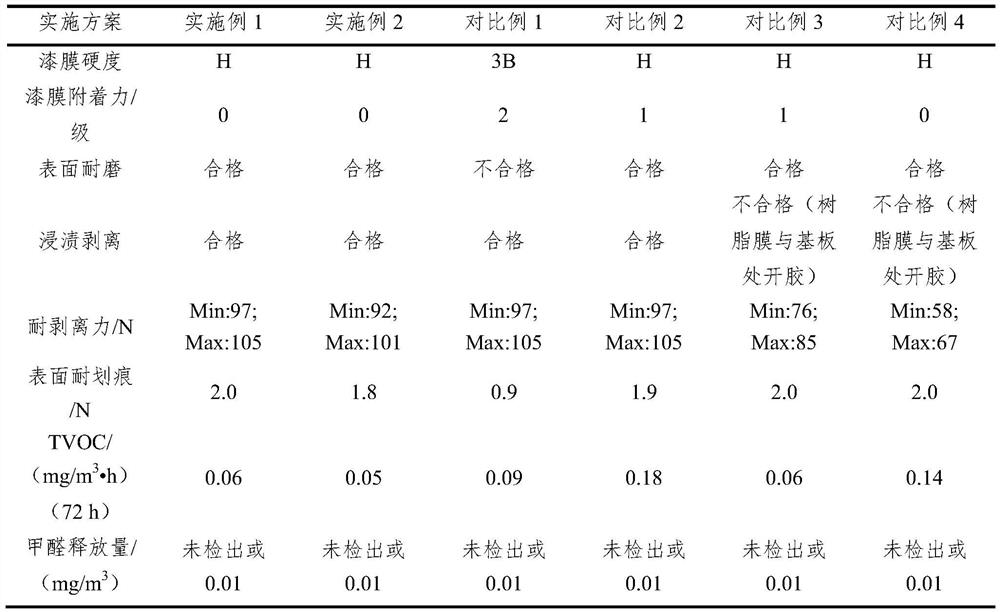

Examples

Embodiment 1

[0034] 1. Preparation of water-based UV topcoat

[0035] Add 80Kg water-based hyperbranched polyurethane acrylate resin (Boxing Science and Technology B-912) in the reactor, under the high-speed dispersion of 2000r, with 3Kg 1173, 2Kg dipropylene glycol monobutyl ether, 1.0Kg polyurethane thickener (Rohm and Haas) RM-2050D), 0.15Kg polyether modified polydimethylsiloxane, 1.0Kg modified castor oil (Senchang Taihe Technology H-870), 5Kg deionized water, stir for 30min until each component is uniformly dispersed and No oil shrinkage;

[0036] 2. Preparation of resin film decorative layer

[0037] Perform plasma treatment on the surface and back of the PVC resin film to obtain the decorative layer of the resin film;

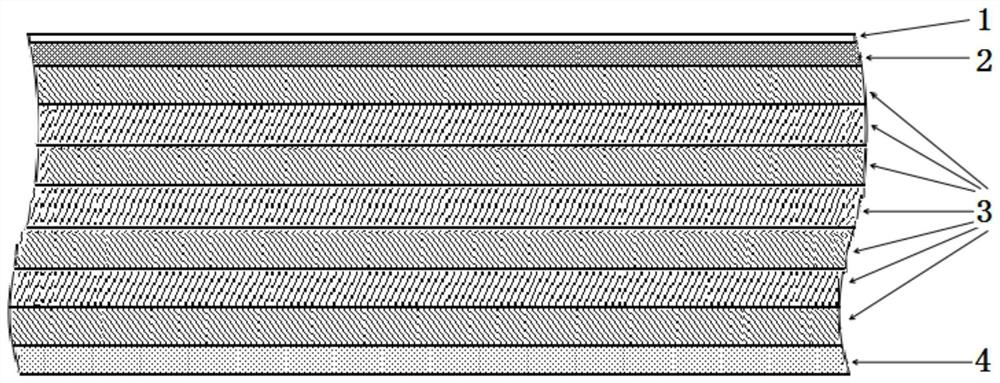

[0038] 3. Preparation of parquet flooring with low VOCs water-based paint resin film veneer

[0039] 1) Coating commercially available formaldehyde-free soybean glue on the surface of eucalyptus veneer with a thickness of 2.2mm, the coating amount is 220g / m 2 , ...

Embodiment 2

[0044] Step 3 production process in embodiment 1 is all unchanged, and change part is as follows:

[0045] 1. Preparation of water-based UV topcoat

[0046] Add 80Kg water-based hyperbranched polyurethane acrylate resin (Changxing Chemical 6196-100) in the reactor, under the high-speed dispersion of 2000r, with 3Kg 1173, 3Kg dipropylene glycol n-butyl ether, 1.5Kg polyurethane thickener (Rohm and Haas RM -12W), 0.13Kg polyether-modified polydimethylsiloxane, 1.1Kg modified castor oil (Senchang Taihe Technology H-854), 10Kg deionized water, stir for 30min, until each component is dispersed evenly and no Oil shrinkage.

[0047] 2. Preparation of resin film decorative layer

[0048] EB electron sputtering treatment is carried out on the surface and back of the PP resin film to obtain the decorative layer of the resin film.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap