Method for preparing surface micro-nano dents based on droplet dissolution

A micro-nano and droplet technology, applied in the process of producing decorative surface effects, manufacturing micro-structure devices, micro-structure technology, etc., can solve problems such as complex operations, strict preparation conditions, and strong professionalism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

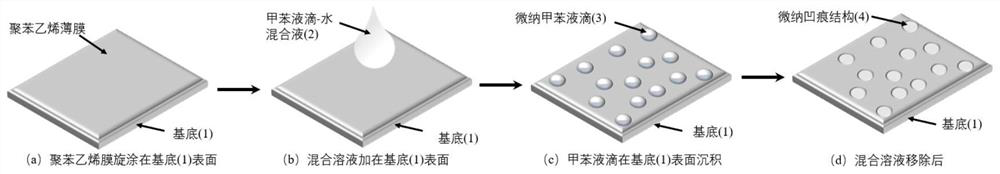

[0012] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be described in further detail below with reference to the accompanying drawings.

[0013] The present invention prepares micro-nano dents on the surface based on droplet dissolution, and realizes the simple, rapid and low-cost preparation of micro-nano dents. The whole preparation process is shown in Figure 1, and the preparation process includes the following steps:

[0014] Step 1: Prepare a mixed solution of toluene droplets, mix the toluene solution into the deionized aqueous solution according to a specific ratio, and at the same time, accompanied by ultrasonic oscillation, at this time, due to the extremely low solubility of toluene in water, part of the toluene solution will be precipitated to form micro-nano toluene droplet;

[0015] Step 2: If figure 1 As shown in (a), get a substrate (1), spin-coat a layer of polystyrene film on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com