Well cementing cement paste suitable for coal bed methane and preparation method thereof

A cementing slurry and coalbed methane technology, which is applied in chemical instruments and methods, solid waste management, and drilling compositions, can solve the lack of research on the damage mechanism, damage method and degree, and the lack of pertinence in the cement slurry system , affect the effect of coal reservoir production increase transformation, etc., to achieve the effect of ensuring strength and toughness, adjustable thickening time, and resisting damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

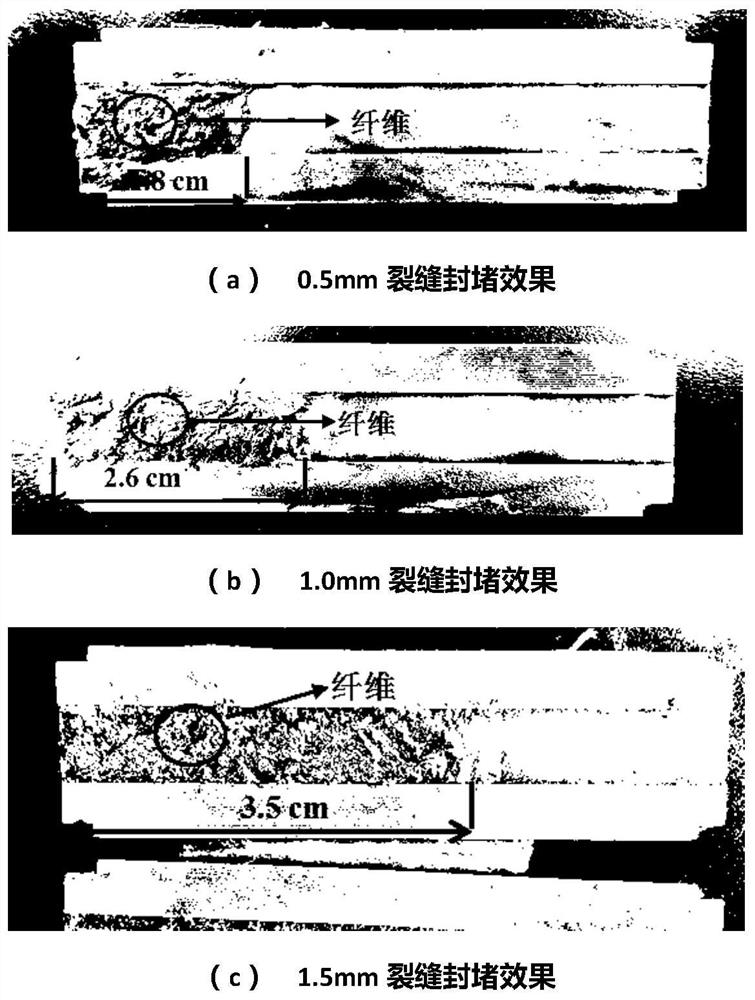

[0090] The multi-grain plugging material is a combination of expanded vermiculite, hydrophilic mixed fiber plugging agent and micro silicon, and the particle size distribution of the expanded vermiculite is 0.90-3.0g / cm 3 , bulk density is 0.7g / cm 3 , the hydrophilic mixed fiber plugging agent is prepared by uniformly mixing polyvinyl alcohol fibers, lignocellulose fibers, and sepiolite fibers in a mass ratio of 3:2:6, and the particle size of the micro-silicon is between 250 and 297μm, bulk density 1.63g / cm 3 , the particles are spherical; the mass ratio of the three components to each other is 15:1:5.

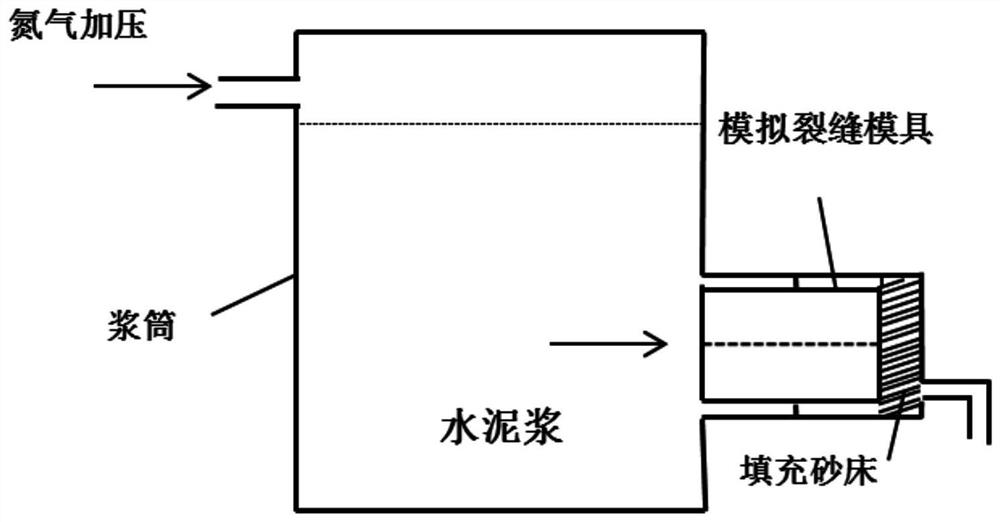

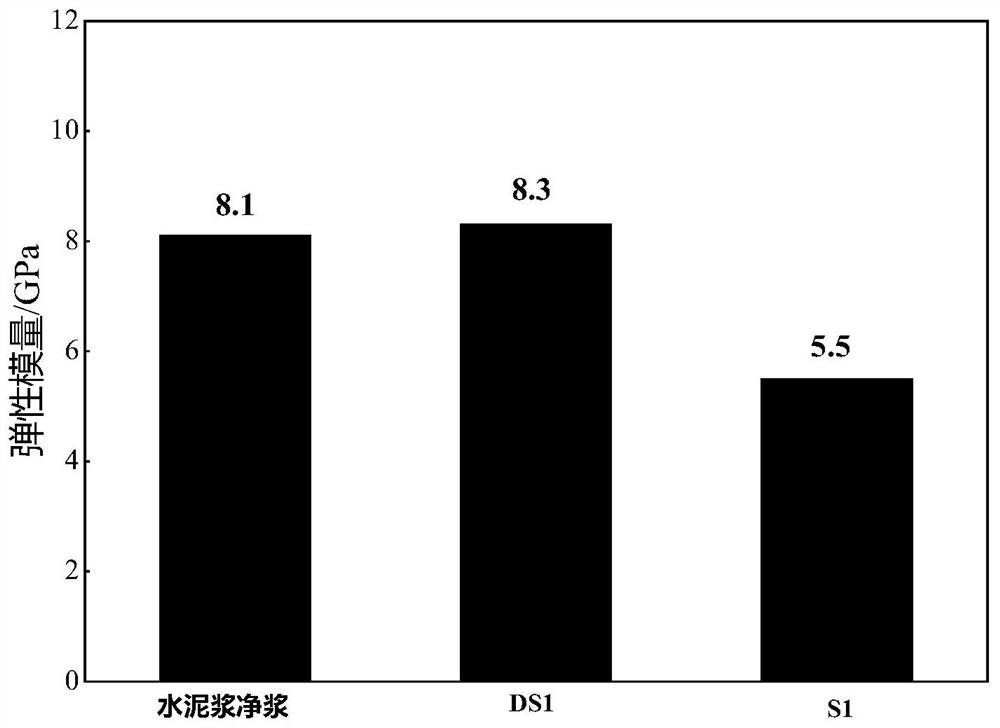

[0091] Taking the above-mentioned multi-grain plugging material as the test object, weigh and mix the solid dry ash component and the liquid water component of the plugging cement slurry system, and then mix them according to the standard GB / T19139-2003 "Oil Well Cement Test Methods" Preparation of cement slurries. Wherein, the composition of the cementing cement slurry is...

Embodiment 2

[0094] According to the same components as in Example 1, a multi-grained leakage plugging material was prepared. The difference is that the mass ratio of polyvinyl alcohol fiber, lignocellulose fiber and sepiolite fiber is 5:4:12. The mass ratio of the three components of expanded vermiculite, hydrophilic mixed fiber plugging agent and micro silicon is 10:1:2.

[0095] Cementing cement slurry was prepared according to the same components as in Example 1, marked as S2.

Embodiment 3

[0097] According to the same components as in Example 1, a multi-grained leakage plugging material was prepared.

[0098] The cementing cement slurry was prepared according to the same components as in Example 1, the difference being: 11.5 parts of multi-grained plugging materials, 4.5 parts of active fillers, 10 parts of resin materials, 4.5 parts of fluid loss reducers, 0.5 parts of dispersants, 60 parts of water, marked as S3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com