Ceramic slurry as well as preparation method and application thereof

A ceramic slurry and raw material technology, applied in the field of ceramic slurry and its preparation, can solve problems such as poor stability, achieve the effects of increased yield and density, easy process control, enhanced strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038]The preparation method of the ceramic slurry in this embodiment is as follows: mixing each raw material component and then ball milling, adding a pH regulator during the ball milling process to adjust the pH value of the ceramic slurry, and the output particle size of the ball milling is 0.5-3 μm.

[0039] In the embodiment of the present application, the ceramic slurry is formed by one-time feeding technology, followed by gel injection molding to form ceramics. The preparation method specifically includes the following steps:

[0040] 1) At 20°C and a humidity of 40%, after mixing the raw material components of each ceramic slurry with a catalyst and an initiator, they are added to the mold at one time for reaction, and then taken out from the mold after the reaction; the catalyst is tetramethanone Ethylenediamine, the initiator is ammonium persulfate;

[0041] 2) Then place it on a flat and air-permeable mesh screen, and let it stand for 10 hours at 20°C and 80% humidi...

Embodiment 1

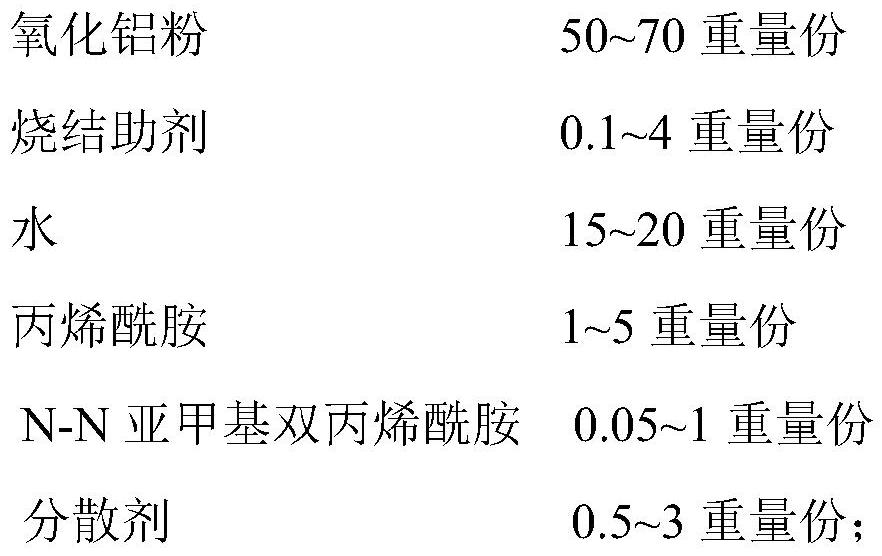

[0048] In the present embodiment, the ceramic slurry comprises the raw material components of the following parts by weight:

[0049]

[0050] The pH value of the ceramic slurry is adjusted to 9-10 by a pH regulator.

[0051] The sintering aid is SiO 2 and TiO 2 According to the 1:1 formed mixture.

[0052] The dispersant in this embodiment is gum arabic powder.

[0053] Test results: The viscosity of the slurry prepared by this method is 175mPa·s, and there is no obvious stratification phenomenon after being placed at room temperature for 15 days. Use this batch of slurry to make ceramic products, the final fired ceramic yield is 93.6%, and the ceramic density is 3.74g / cm 3 ; The dimensional tolerance of ceramic products over 30mm is controlled within 1%.

Embodiment 2

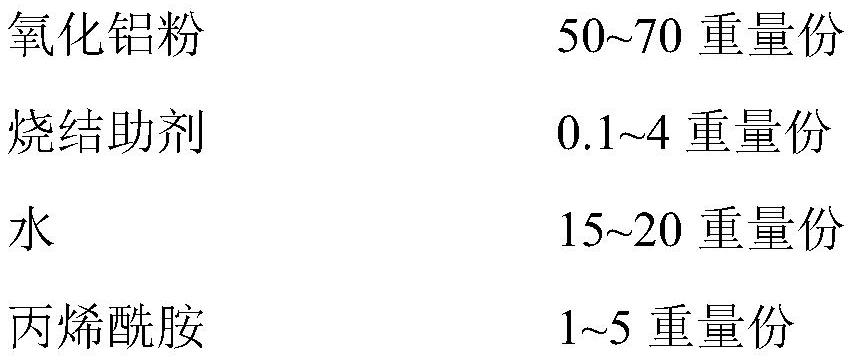

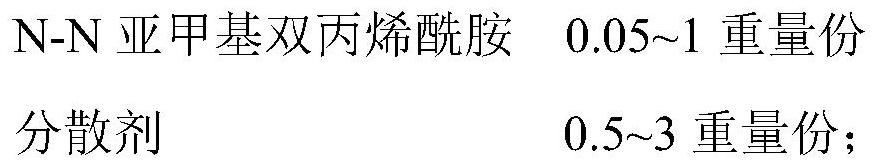

[0055] In the present embodiment, the ceramic slurry comprises the raw material components of the following parts by weight:

[0056]

[0057] The pH value of the ceramic slurry is adjusted to 9-10 by a pH regulator.

[0058] The dispersant in this embodiment is gum arabic powder.

[0059] The sintering aid is SiO 2 and CaCO 3 According to the 1:1 formed mixture.

[0060] Test results: The viscosity of the slurry prepared by this method was 330mPa·s, and it was left at room temperature for 15 days without obvious stratification. Use this batch of slurry to make ceramic products, the final fired ceramic yield is 93%, and the ceramic density is 3.70g / cm 3 , The dimensional tolerance of ceramic products over 30mm is controlled within 1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com