Ferrite material with high dielectric constant

A ferrite material, high dielectric constant technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

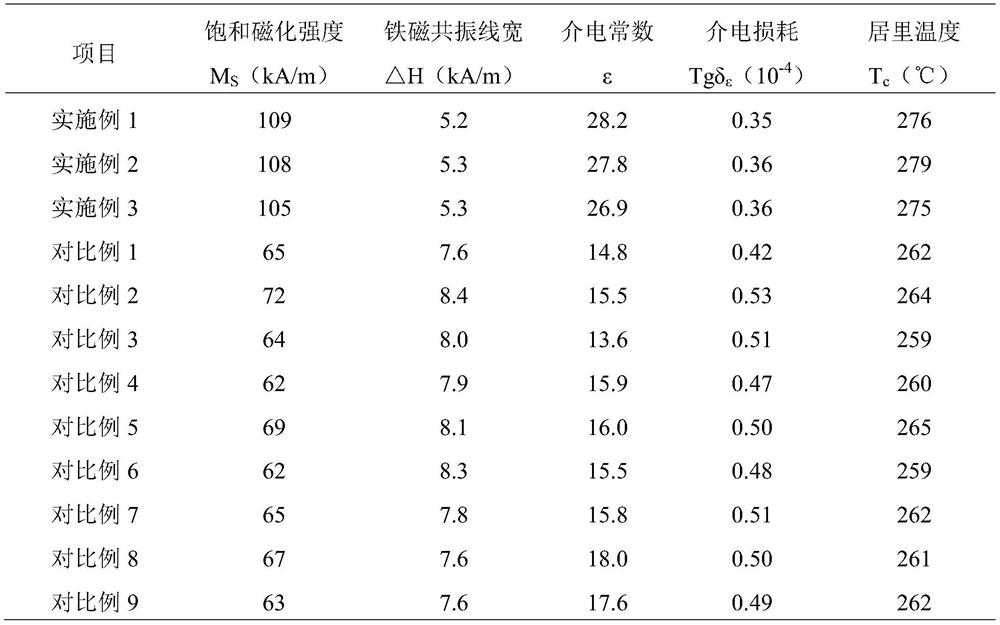

Examples

preparation example Construction

[0029] The preparation method of described ferrite material, comprises the steps:

[0030] S1. Ferric nitrate and citric acid are mixed, add deionized water to dissolve, obtain the first solution, in this solution, the total molar concentration of ferric nitrate and citric acid is controlled at 1.0mol / L;

[0031] S2. Tetrabutyl titanate and citric acid are mixed, dissolved in analytical grade ethanol to obtain a second solution, and the total molar concentration of tetrabutyl titanate and citric acid in the solution is controlled at 1.5mol / L;

[0032] S3. Slowly add the second solution to the first solution, and stir evenly to obtain the third solution;

[0033] S4. Adjust the pH of the third solution to 10-13 with 2mol / L sodium hydroxide solution, then heat to volatilize the solvent, and then dry the obtained sol at 135° C. to obtain a fluffy xerogel;

[0034] S5. heat-treating the fluffy xerogel at 520°C for 2 hours, and then heat-treating the product at 980-1050°C for 1-2 ...

Embodiment 1

[0040] A ferrite material with a high dielectric constant, the ferrite material is a single-phase material, part of the iron ions in the ferrite are replaced by titanium ions, cerium ions and zinc ions, and the titanium ions are replaced by positively charged Ti 4+ Ions exist, and cerium ions are positively charged Ce 4+ Ions exist, and zinc ions are positively charged Zn 2+ ions exist, the iron ions in ferrite are Fe 3+ and Fe 2+ Ionic forms coexist, according to the chemical formula of the ferrite material Fe 12-x-y-z-δ Ti x Ce y Zn z o 18 , wherein, x=0.6, y=0.5, z=0.4, iron deficiency amount δ=0.06, calculate the amount of raw materials;

[0041] The preparation method of described ferrite material, comprises the steps:

[0042] S1. Ferric nitrate and citric acid are mixed, add deionized water to dissolve, obtain the first solution, in this solution, the total molar concentration of ferric nitrate and citric acid is controlled at 1.0mol / L;

[0043] S2. Tetrabutyl ...

Embodiment 2

[0055] A ferrite material with a high dielectric constant, the ferrite material is a single-phase material, part of the iron ions in the ferrite are replaced by titanium ions, cerium ions and zinc ions, and the titanium ions are replaced by positively charged Ti 4+ Ions exist, and cerium ions are positively charged Ce 4+ Ions exist, and zinc ions are positively charged Zn 2+ ions exist, the iron ions in ferrite are Fe 3+ and Fe 2+ Ionic forms coexist, according to the chemical formula of the ferrite material Fe 12-x-y-z-δ Ti x Ce y Zn z o 18 , wherein, x=0.8, y=0.3, z=0.5, iron deficiency amount δ=0.02, calculate the amount of raw material;

[0056] The preparation method of described ferrite material, comprises the steps:

[0057] S1. Ferric nitrate and citric acid are mixed, add deionized water to dissolve, obtain the first solution, in this solution, the total molar concentration of ferric nitrate and citric acid is controlled at 1.0mol / L;

[0058] S2. Tetrabutyl t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com