Device and method for enhancing magnetic resin desorption

A magnetic resin and desorption technology, applied in chemical instruments and methods, magnetic field/electric field water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of desorption and adsorption efficiency decline, resin accumulation, blocked pipes, etc. , to achieve full reaction, reduce usage, and avoid blockage of pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

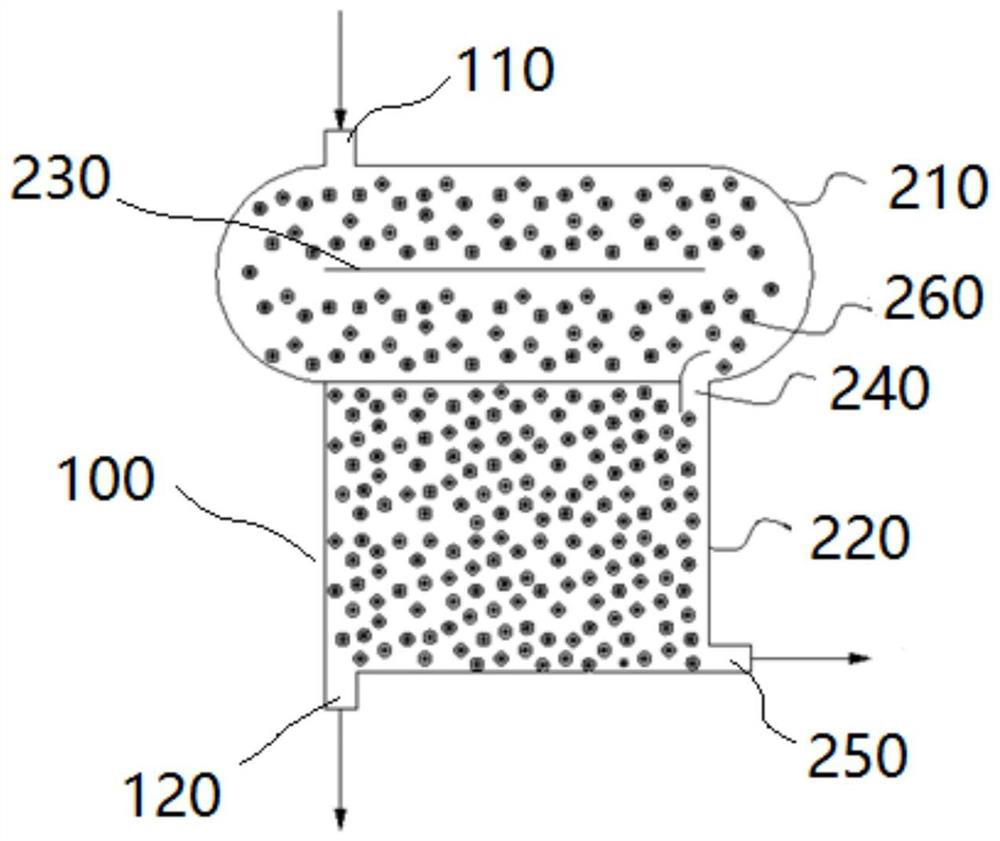

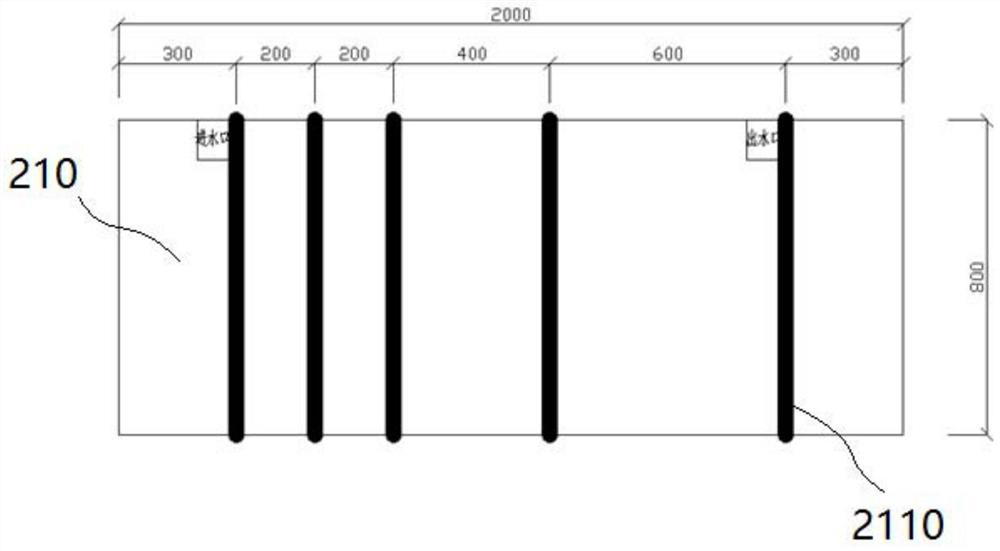

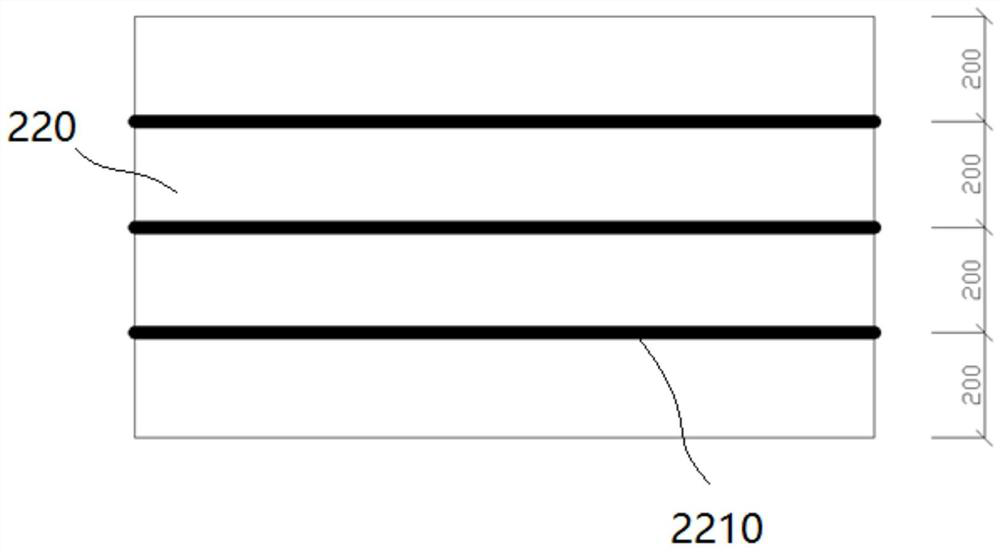

[0047] A device for strengthening magnetic resin desorption in this embodiment includes a device body 100, a water inlet 110, a water outlet 120, a reaction zone 210, a precipitation zone 220, a water hole 240, a silicon-based separator 230 and an ammonia nitrogen adsorption saturated The magnetic resin 260; wherein, the silicon-based separator is located in the middle of the reaction zone 210, the outer layer of the reaction zone 210 is regularly equipped with a first silicon-based hoop 2110, and the outer layer of the precipitation zone 220 is regularly equipped with a second silicon-based hoop. base hoop 2210;

[0048] The width of the first silicon-based hoop 2110 of the reaction zone 210 is 1 cm, and the distances from the side near the water inlet 110 of the reaction zone 210 to the side near the water hole 240 are respectively 150 cm, 150 cm, 300 cm, and 450 cm; The width of the second silicon-based hoop 2210 of 220 is 15 cm, and the distance from the top of the precipi...

Embodiment 2

[0052] The basic content of this embodiment is the same as that of Embodiment 1, except that the width of the first silicon-based hoop 2110 of the reaction zone 210 is 3 cm, from the side near the water inlet 110 of the reaction zone 210 to the water hole 240 The spacing on one side is 180cm, 180cm, 360cm, and 540cm respectively; the width of the second silicon-based hoop 2210 of the precipitation zone 220 is 20cm, and the distance from the top of the precipitation zone 220 to the bottom of the precipitation zone 220 is the same, and the spacing is 200cm. Moreover, the radius of the water hole 240 is 1 / 4 of the radius of the reaction zone 210, and the aspect ratio of the reaction zone 210 is 1:5. The residence time of the magnetic resin 260 in the reaction zone 210 is 0.5h.

[0053] After being treated by the magnetic resin desorption device of this embodiment, the desorption efficiency of the magnetic resin reaches 97%, and the adsorption efficiency reaches the original 92%. ...

Embodiment 3

[0055] The basic content of this embodiment is the same as that of Embodiment 1, except that the width of the first silicon-based hoop 2110 of the reaction zone 210 is 5 cm, from the side near the water inlet 110 of the reaction zone 210 to the water hole 240 The spacing on one side is 200cm, 200cm, 400cm, and 600cm respectively; the width of the second silicon-based hoop 2210 of the precipitation zone 220 is 25cm, and the distance from the top of the precipitation zone 220 to the bottom of the precipitation zone 220 is the same, and the spacing is 250cm. Moreover, the radius of the water hole 240 is 1 / 5 of the radius of the reaction zone 210, and the aspect ratio of the reaction zone 210 is 1:8. The residence time of the magnetic resin 260 in the reaction zone 210 is 1 h.

[0056] After being treated by the magnetic resin desorption device of this embodiment, the desorption efficiency of the magnetic resin reaches 97%, and the adsorption efficiency reaches 94% of the original...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com