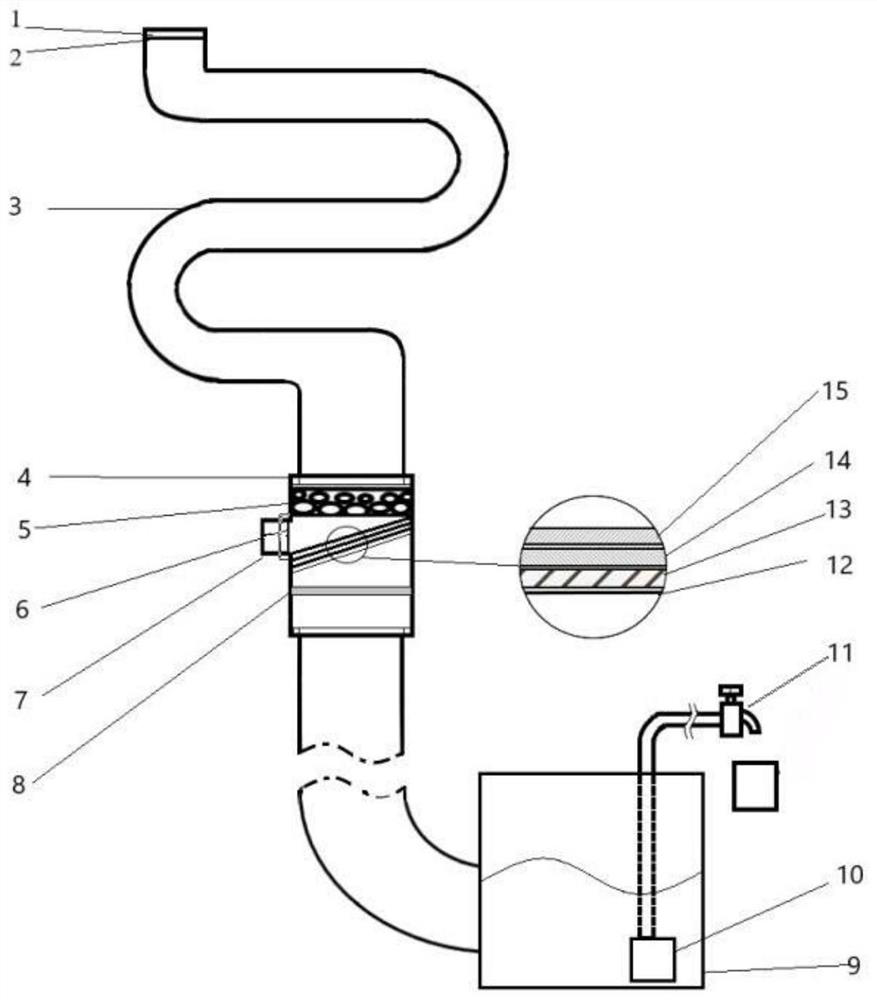

Efficient oil-water separation device based on electrostatic spinning nanofiber membrane

A technology of oil-water separation device and nanofiber membrane, which is applied in oil/oily substance/float removal device, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of short service life and anti-pollution ability of nanofiber membrane. problems such as poor separation, to achieve the effects of high separation efficiency, saving water resources, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] First, a small amount of water is added to the device of the present invention to infiltrate the device, and 250 mL of diesel oil is mixed with 1000 mL of aqueous solution to make a diesel-water mixture. The device is used for oil-water separation, and the filtering effect is good, and the separation efficiency reaches 99%. The volume is about 1215~1500L·m -2 h -1 .

Embodiment 2

[0035] First, a small amount of water is added to the device of the present invention to infiltrate the device, and 250 mL of vegetable oil (viscous compared with diesel oil) is mixed with 1000 mL of aqueous solution to make a vegetable oil-water mixture. The device is used for oil-water separation, and the filtering effect is good. The separation efficiency is up to 99%, and the water flux is about 1190~1362L m -2 h -1 .

Embodiment 3

[0037] First, add a small amount of water to the device of the present invention to infiltrate the device, mix 25mL of diesel oil with 1000mL of aqueous solution, add 10mL of Tween 80, stir and emulsify at 100r / min to make an oil-in-water emulsion, and use this device for oil-water Separation, good filtration effect, separation efficiency of 99%, water flux of about 730 ~ 981L m -2 h -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com