Water-soluble phosphorus-potassium-calcium-magnesium nitrate fertilizer and preparation method thereof

A technology of potassium phosphorus nitrate and magnesium nitrate hexahydrate, applied in the field of water-soluble phosphorus potassium nitrate calcium magnesium fertilizer and preparation thereof, can solve the problems of high viscosity, easy to break granules, etc. The effect of high grain rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The present invention provides a method for preparing a water-soluble nitrate and potassium calcium magnesium fertilizer, including the following steps:

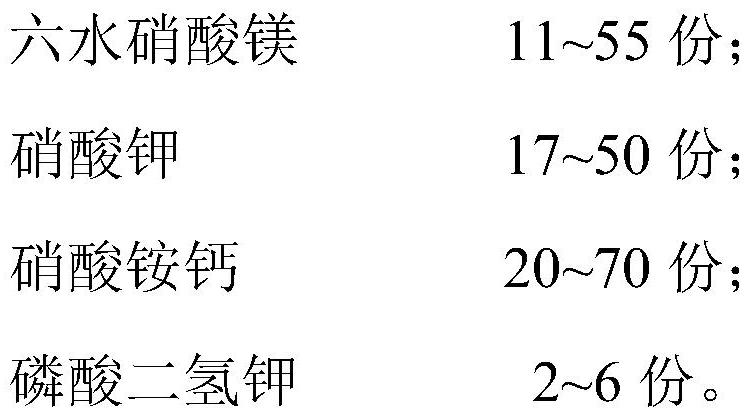

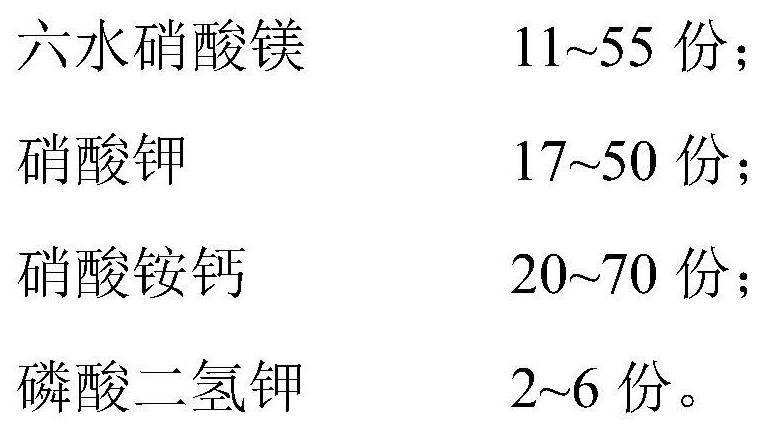

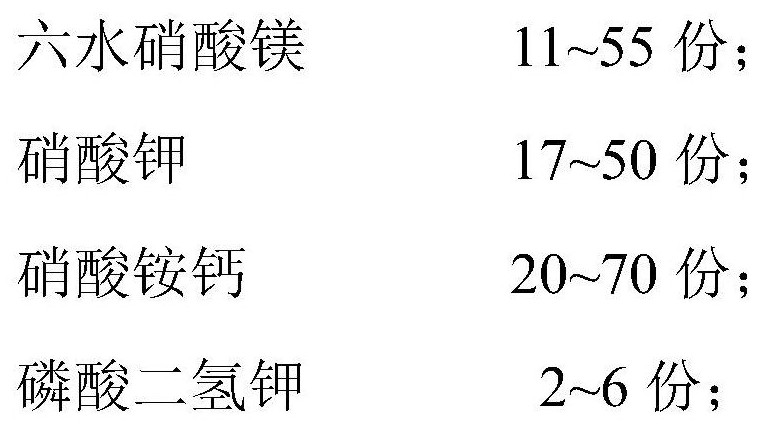

[0018] S01. The raw material of the water-soluble nitrate, potassium calcium magnesium fertilizer, including six-sme magnesium nitrate, potassium nitrate, ammonium nitrate, potassium phosphate;

[0019] S02. A magnesium nitrate is heated melt to obtain six oxiditrate slurry;

[0020] S03. Potassium nitrate, ammonium nitrate, mixed with a high speed shear to obtain a first mixture, the first mixture and the heating melt-obtained six-nitrate slurry mixed to obtain the first The second mixture was low-speed granulation, cooled, sieve, cooled, cooled, cooled, cuveridium magnesium, and magnesium, which was ≥ 85%.

[0021] Specifically, in the above-described step S01, the raw material of the water-soluble nitrate phosphate calcium magnesium plant is weighed, the raw material comprising six-sme-magnesium nitrate, potassium nitr...

Embodiment 1

[0042] The water-soluble nitrate, phosphate calcium magnesium fertilizers include the following weight components: 14 parts of sampling of signs; 46 potassium nitrate; 37 ammonium nitrate; 3 copper phosphate.

[0043] The preparation method of the hydrolysis of phosphorium calcium magnesium fertilizer is as follows: the raw material of the water-soluble nitrate and potassium calcium magnesium fertilizer, including 14 parts of six-nitrate; 46 potassium nitrate; ammonium nitrate calcium 37 Part; 3 copper phosphate and 3 parts;

[0044] The six-squeezide magnesium sampling was heated at 102 ° C to give no six oxyzon nitrate slurry;

[0045] Potassium nitrate, ammonium ammonium nitrate, mixed with a high speed shear to obtain a first mixture, the high speed shear of 2000 r / min, and the high speed shear time is 2 minutes. The six-membered nitrate magnesium obtained by the first mixture with the heating melting will be mixed to obtain a second mixture, and the second mixture is low-sp...

Embodiment 2

[0048] The water-soluble nitrate phosphate calcium magnesium fertilizers include 45 parts by weight of sampling of six, 18 nitrate; potassium nitrate; 39 ammonium nitrate; 6 copper phosphate.

[0049] The preparation method of the water-soluble nitrate phosphate calcium magnesium fertilizer is suggested with the material of the water-soluble nitrate, the raw material comprising 45 parts of six-water nitrate; 18 parts of nitrate; ammonium nitrate calcium 31 Part; 6 podium phosphate;

[0050] The six-squeezide magnesium gave melt to 104 ° C to give no six-nitrate slurry;

[0051] Potassium nitrate, ammonium nitrate, mixed with a strong mixed granule machine, and perform high-speed shearing to obtain a first mixture, the high speed shear rotation speed of 1800R / min, said The high-speed shear is 1 minute; the six-membered nitrate magnesium gave the first mixture with the heated melt will mix the second mixture, and the second mixture is low-speed granulation, cooling, screening, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com