Quantum dot composite material and preparation method thereof

A composite material and quantum dot technology, which is applied in the field of quantum dot composite materials and its preparation, can solve the problems of energy transfer and self-absorption of inorganic semiconductor quantum dots, so as to avoid energy transfer and self-absorption, increase blue light absorption, and improve photoelectric conversion efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

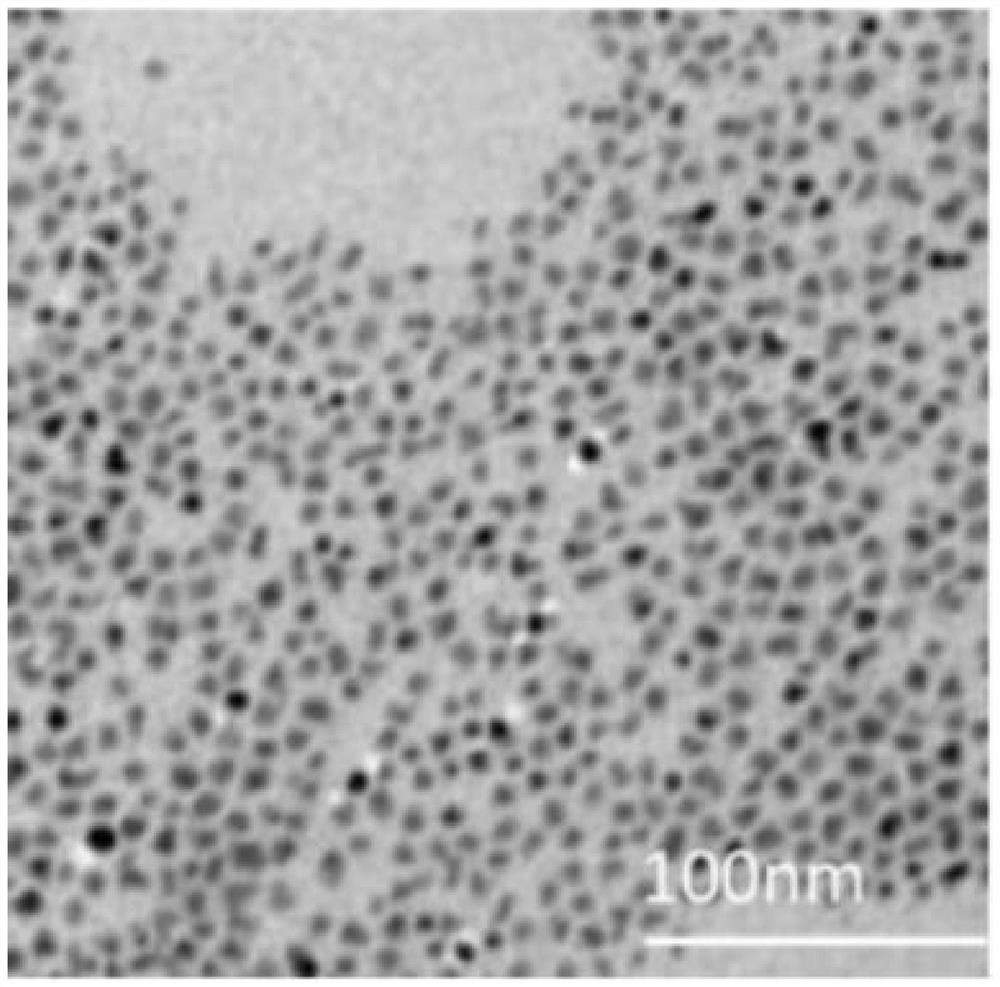

[0039] CdZnSeS / cesium lead bromide (CsPbBr 3 ) synthesis of quantum dots. 1mmol ZnBr 2 , 1.2mL oleylamine, 1mL oleic acid, and 10mL ODE were mixed in a 100mL three-necked flask, heated to 120°C for 10 minutes, injected with CdZnSeS alloy quantum dots with an absorbance of 50 at 450nm (the fluorescence peak position is 525nm), and raised the temperature to 200°C, react for 5 minutes, ligand exchange. Cool down to 150°C, add 0.4 mL of 0.5 mmol / mL lead oleate and 1 mL of 0.2 mmol / mL cesium oleate solution, react for 5 minutes, and stop the reaction.

Embodiment 2

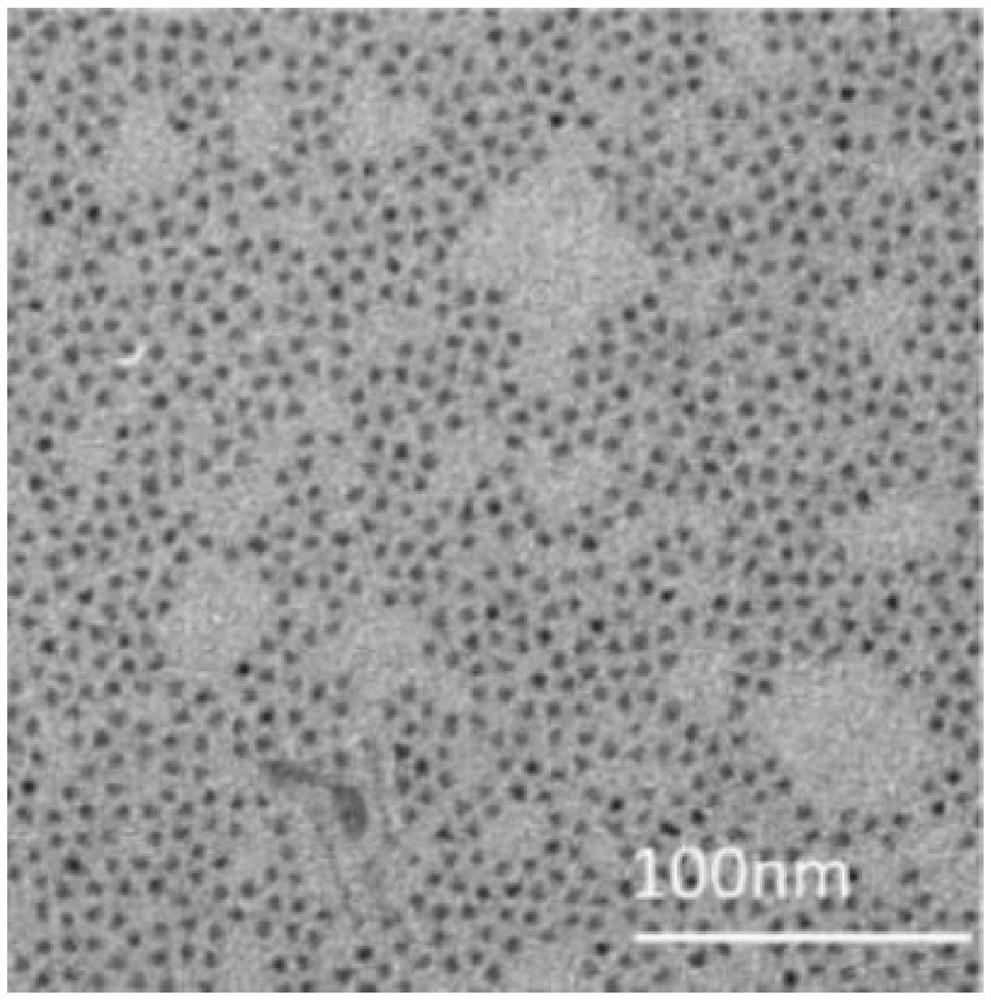

[0041] CdZnSeS / cesium lead chloride (CsPbCl 3 ) synthesis of quantum dots. 1mmol ZnCl 2, 1.2mL oleylamine, 1mL oleic acid, and 10mL ODE were mixed in a 100mL three-necked flask, heated to 120°C for 10 minutes, injected with CdZnSeS alloy quantum dots with an absorbance of 50 at 450nm (the fluorescence peak position is 525nm), and raised the temperature to 200°C, react for 5 minutes, ligand exchange. Cool down to 150°C, add 0.4 mL of 0.5 mmol / mL lead oleate and 1 mL of 0.2 mmol / mL cesium oleate solution, react for 5 minutes, and stop the reaction.

Embodiment 3

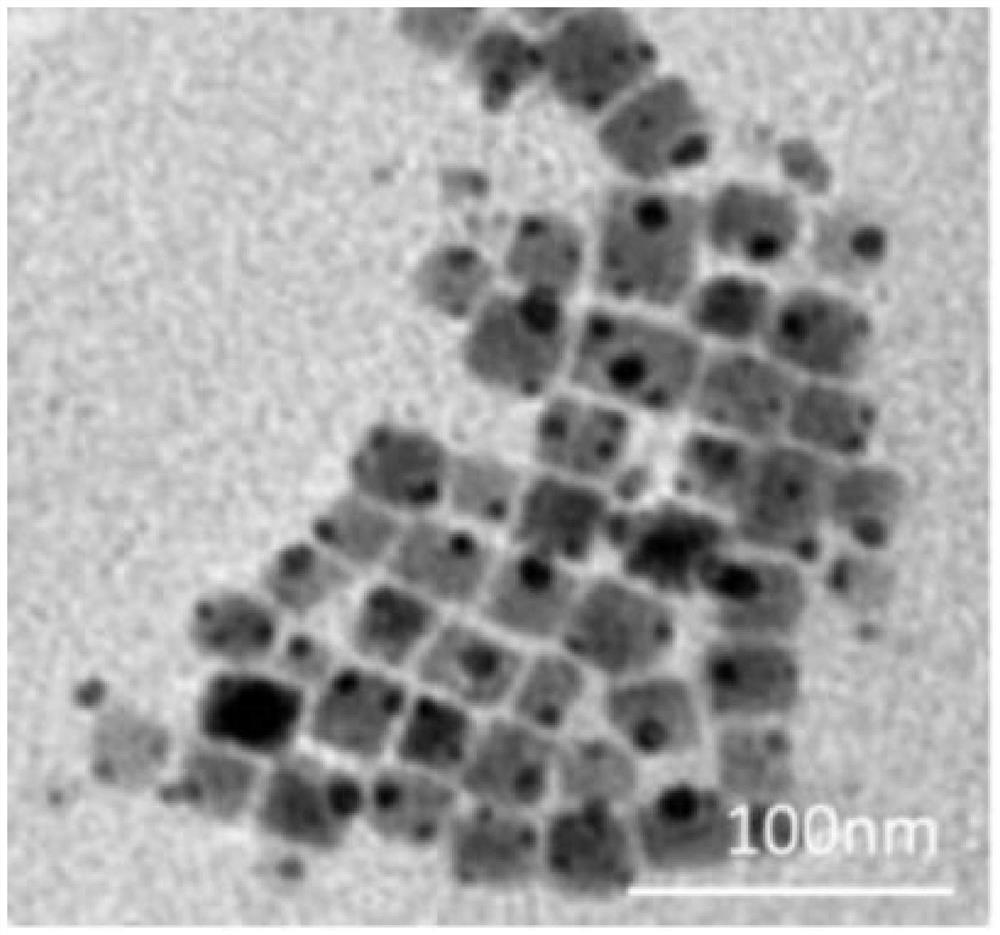

[0043] CdZnSeS / cesium lead iodide (CsPbI 3 ) synthesis of quantum dots. 1mmol ZnI 2 , 1.2mL oleylamine, 1mL oleic acid, and 10mL ODE were mixed in a 100mL three-necked flask, heated to 120°C for 10 minutes, injected with CdZnSeS alloy quantum dots with an absorbance of 50 at 450nm (the fluorescence peak position is 525nm), and raised the temperature to 200°C, react for 5 minutes, ligand exchange. Cool down to 150°C, add 0.4 mL of 0.5 mmol / mL lead oleate and 1 mL of 0.2 mmol / mL cesium oleate solution, react for 5 minutes, and stop the reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com