Cladosporium sp. and application thereof in degradation of polyurethane plastic

A technology of Cladosporium and polyurethane, which is applied in the field of biological treatment, can solve the problems of lack of recycling, ecosystem damage, threat, etc., and achieve high degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

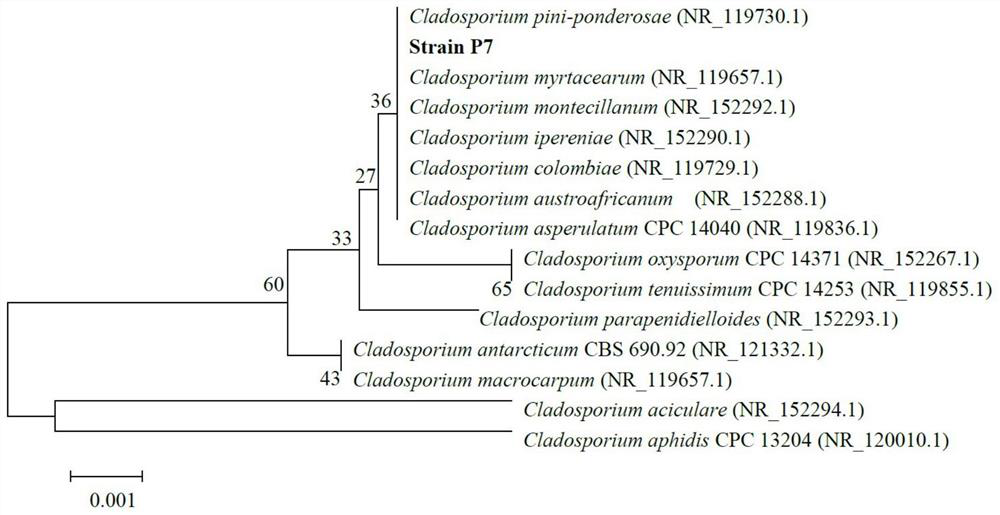

[0032] Example 1: Isolation, screening and strain identification of the highly efficient Impranil DLN strain Cladosporium sp.P7

[0033] Take 5g landfill soil samples and place them in 100mL enrichment medium containing 0.2% (v / v) Impranil DLN, and culture them at 30°C and 180rpm for 7 days. Measure the degradation situation to Impranil DLN in the enrichment solution with ultraviolet spectrophotometer, after confirming that Impranil DLN is degraded, insert with the inoculation amount of 10% (v / v) to contain 0.4% (v / v) Impranil DLN rich Collect in the culture medium, continue to enrich and measure the degradation situation, follow this method until the concentration of Impranil DLN increases to 1% (v / v), and then pass for 4 times.

[0034] The Impranil DLN enrichment solution was serially diluted and spread on an inorganic salt plate with 1% (v / v) Impranil DLN as the sole carbon source, and cultured in a 30°C incubator for 1-7 days. Single colonies with different colony shapes...

Embodiment 2

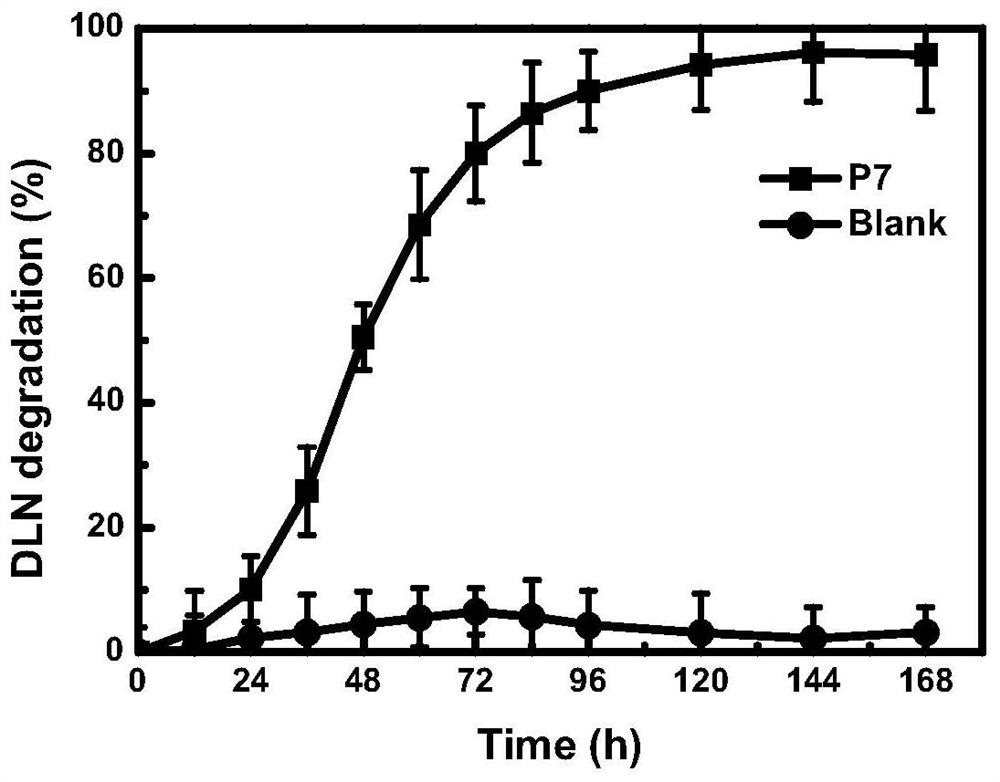

[0038] Example 2: The degradation curve of Cladosporium sp.P7 to Impranil DLN and the change of esterase activity during the degradation process

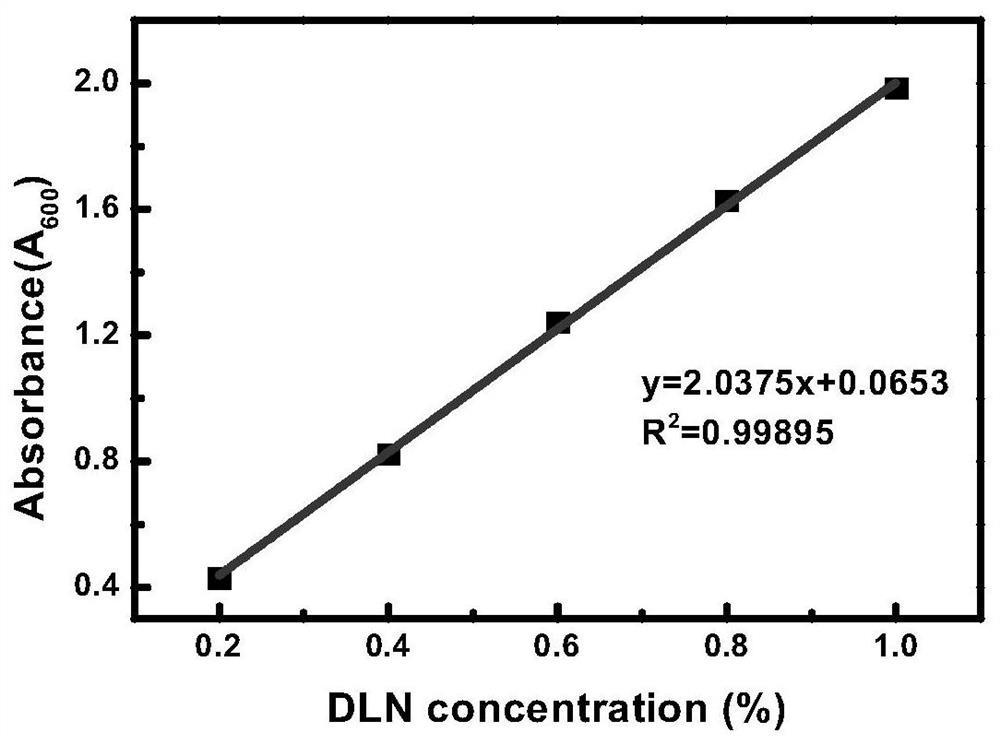

[0039] (1) The making of different concentrations of Impranil DLN standard music: respectively configure the Impranil DLN inorganic salt culture medium with concentrations of 0.2, 0.4, 0.6, 0.8, 1.0% (v / v) (wherein 1% v / v is equal to 6g / L DLN), respectively in OD 600nm Determination, drawing a standard curve, such as figure 1 shown.

[0040] The calculation of DLN degradation rate is published as follows:

[0041] DLN degradation rate%=(initial concentration-final concentration) / initial concentration*100%

[0042] (2) Wash the P7 mycelium from the PDA flat plate with sterile water, scrape the mycelium and spores on the surface with a coating stick, count through the hemocytometer, and make a final concentration of 1 × 10 6 The bacterial suspension with spore / mL concentration is the seed solution.

[0043] (3) In the inorganic s...

Embodiment 3

[0045] Embodiment 3: Research on the degradation performance of Impranil DLN by Cladosporium sp.P7

[0046] Will 1×10 6 The seed solution of spore / mL was inserted into the inorganic salt medium with the final concentration of Impranil DLN of 1% (v / v) at 10% (v / v) inoculum amount, respectively at 20, 25, 30, 37 and 42 °C, 120rpm shaker cultured for 7 days, detected the residual amount of Impranil DLN, calculated the degradation rate, and studied the effect of temperature on the degradation of Impranil DLN. Such as Figure 5 As shown in a, the optimal degradation temperature of strain P7 is 30°C, at this time the degradation rate of Impranil DLN is the highest, and the degradation rate is 97%; when the temperature is 25°C and 37°C, the degradation percentages of strain P7 are 88% and 77%; when the temperature is lower (20°C) or higher (42°C), the degradation rate of strain P7 to Impranil DLN is lower than 40%. This shows that low temperature is not conducive to the degradatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com