Preparation method of squid chondroitin sulfate glycoprotein

A technology of chondroitin sulfate and squid cartilage, which is applied in the field of extracting glycoproteins, can solve the problems of low extraction rate, high protein content, complicated process, etc., and achieve the effects of high extraction rate, high product purity and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

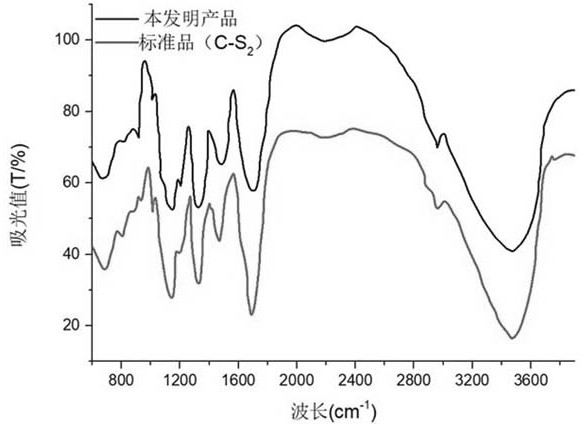

Image

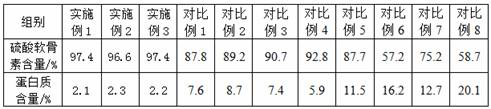

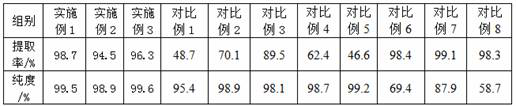

Examples

Embodiment 1

[0030] A preparation method of squid chondroitin sulfate glycoprotein, which goes through the following processing steps:

[0031] 1) Preparation of chondroitin sulfate lyase-producing bacteria

[0032] Take fresh duck small intestines, taken from ducks fed with shrimp and crab shells for 2 years, crush them with a wall breaker, add sterile water at 1:5.5 by weight to prepare duck small intestine solution, stir for 18 minutes, and filter through a 180-mesh sieve , then take the filtrate coating culture medium, carry out plate culture separation, then pick a single colony, and purify with the method of slant streaking; prepare a medium containing squid cartilage powder, plant the purified single colony on the medium plate, 32 Cultivate at a constant temperature of ℃ for 1 day, pour sterile water into the plate, and soak for 4 minutes; pick out the strains that produce transparent circles, use a slant to culture, control the temperature at 32 ℃, 140r / min shake aerobic culture fo...

Embodiment 2

[0043] A preparation method of squid chondroitin sulfate glycoprotein is characterized in that it undergoes the following processing steps:

[0044] 1) Preparation of chondroitin sulfate lyase-producing bacteria

[0045]Take fresh duck small intestines, taken from ducks that have been fed with shrimp and crab shells for 2 years, crush them with a wall breaker, add sterile water at a ratio of 1:5 by weight to prepare duck small intestine solution, stir for 10 minutes, and filter through a 160-mesh sieve , then take the filtrate coating medium, carry out plate culture separation, then pick a single colony, and purify it with the slant method; prepare a medium containing squid cartilage powder, plant the purified single colony on the medium plate, 30 Cultivate at a constant temperature of ℃ for 1 day, pour sterile water into the plate, and soak for 3 minutes; pick the strain that produces a transparent circle, use a slant to culture, control the temperature at 30 ℃, 120r / min shak...

Embodiment 3

[0056] A preparation method of squid chondroitin sulfate glycoprotein is characterized in that it undergoes the following processing steps:

[0057] 1) Preparation of chondroitin sulfate lyase-producing bacteria

[0058] Take fresh duck small intestines, taken from ducks that have been fed with shrimp and crab shells for 3 years, crush them with a wall breaker, add sterile water at a ratio of 1:6 by weight to prepare duck small intestine solution, stir for 20 minutes, and filter through a 180-mesh sieve , then take the filtrate to coat the medium, carry out plate culture and isolation, then pick a single colony, and purify it with the method of streaking on a slant; prepare a medium containing squid cartilage powder, plant the purified single colony on the medium plate, 37 Cultivate at a constant temperature of ℃ for 3 days, pour sterile water into the plate, and soak for 5 minutes; pick out the strains that produce transparent circles, use a slant to culture, control the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com