Steam air preheating system and method for waste incineration industry

A waste incineration and air preheating technology, applied in combustion methods, steam/steam condensers, lighting and heating equipment, etc., can solve problems such as high failure rate of traps, water hammer in pipelines, difficult performance comparison, etc., to achieve Save procurement costs, avoid shocks, and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

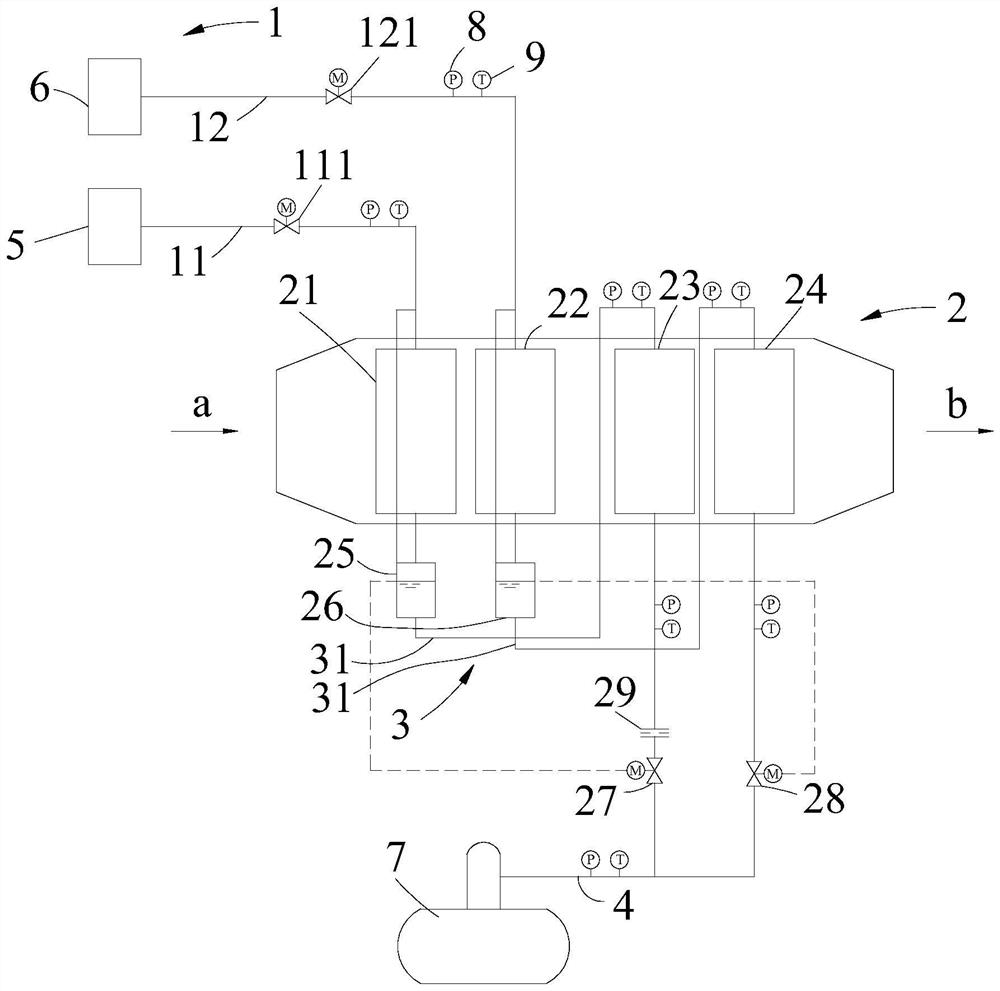

[0033] figure 1 A structural block diagram of a steam air preheating system for the waste incineration industry of the present invention.

[0034] In this embodiment, if figure 1 As shown, the present embodiment provides a steam air preheating system for a waste incineration industry comprising: an ejector line 1, a heat exchanger 2, a hydrophobic group 3, a hydrophobic female tube 4; wherein the steam The pipe 1 is adapted to extract steam in the steam in the steam in the steam in the steam in the steam in the steam in the steam, and the air is absorbed from the heat exchanger 2 to form a hot air discharge; the steam condensed in the heat exchanger 2 is formed. The condensed water flows through the hydrophobic group 3 and is recovered from the hydrophobic mother tube 4 to the corresponding container.

[0035] In the present embodiment, the heat source is a steam of the steam of the air bag 5 and the steam turbine.

[0036] In this embodiment, please refer to figure 1 The soli...

Embodiment 2

[0054] figure 2 It is a flow chart of a steam air preheating method for the waste incineration industry of the present invention.

[0055] On the basis of Example 1, if figure 2 As shown, this embodiment provides a steam air preheating method for the waste incineration industry, including: extracting steam and air heat transfer in the steam turbine to form hot air; recovering steam and air heat transfer formation Hydrophobic.

[0056] In the present embodiment, a steam air preheating system for use in the waste incineration industry as in Example 1 is employed.

[0057] In the present embodiment, the steam air preheating system for the waste incineration industry has been clarified in the above embodiment.

[0058] In summary, the present invention degraded the condensed water temperature after steam heat transfer by high-pressure cooling technique to 100 ° C or lower, ensuring that the pressure decreased to the corresponding container pressure, and did not produce secondary flas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com