Folic acid derived Cu-CoNCNs catalyst and preparation and application thereof

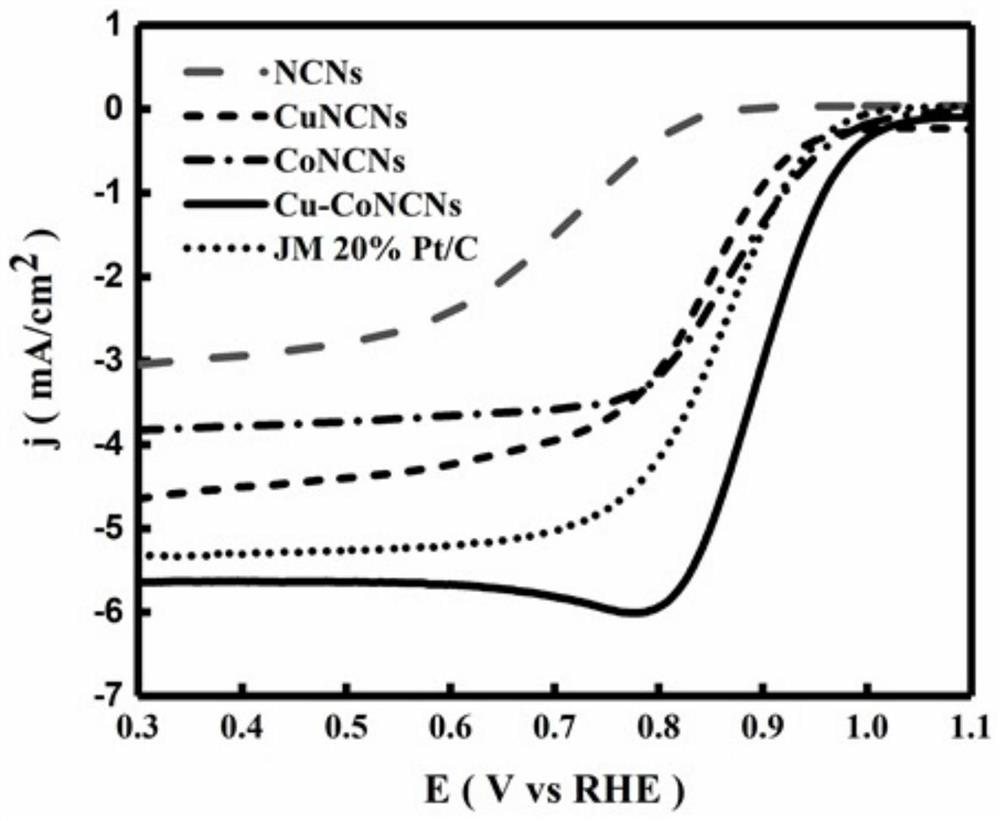

A catalyst, folic acid technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of slow kinetics, poor anti-toxic ability, low stability, etc., and achieve good stability, low price, high stability and resistance. The effect of methanol performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] A preparation method of Cu-CoNCNs catalyst derived from folic acid, specifically comprising the following steps:

[0050] (a) Use NaOH with a concentration of 0.1-0.5M to adjust the pH of the folic acid solution, add cobalt salts and copper salts to form a reaction solution at 60-65 Heat the reaction at ℃ for 30-40min, cool the reaction solution to room temperature, centrifuge at a speed of 4000-6000r / min for 2-4min, wash with organic solvent for 2 to 3 times, and dry under vacuum , the drying temperature is 50-70°C, and the drying time is 10-14h to obtain the Cu-CoNCNs catalyst precursor;

[0051] (b) Mix the Cu-CoNCNs catalyst precursor prepared in step (a) with NaCl evenly, and then grind for 30-40 minutes, calcinate at 700-900°C for 1-2 hours, cool to room temperature and use water for the first washing for the first time to obtain an intermediate, which is dried for the first time, etched with hydrochloric acid with a concentration of 1-2M, washed for the second t...

Embodiment 1

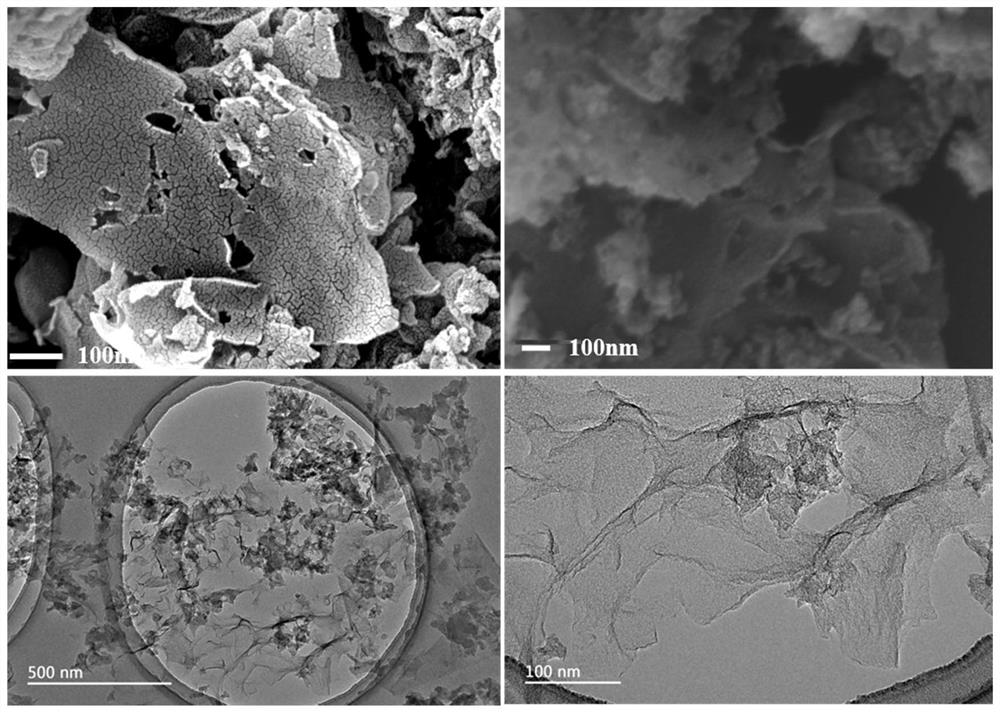

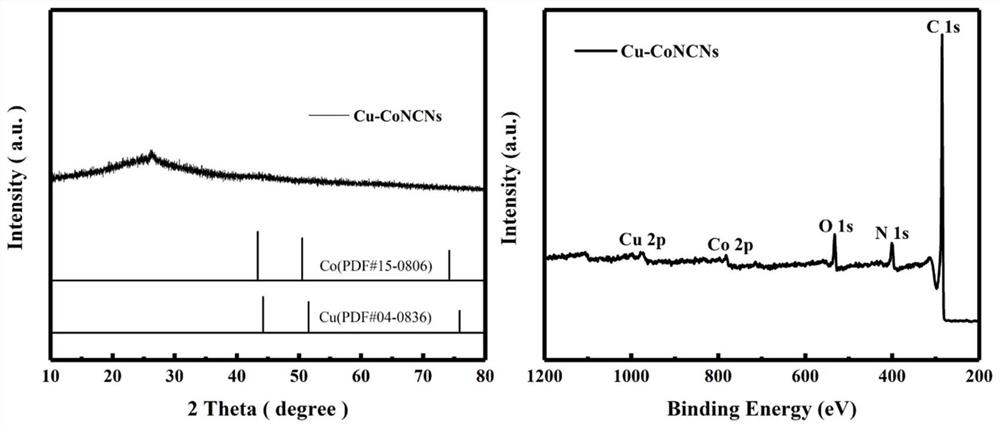

[0056] A Cu-CoNCNs catalyst derived from folic acid, the catalyst is a porous sheet structure, the atomic percentage content of Cu is 0.1%, and the atomic percentage content of Co is 0.35% (this value is measured by XPS full spectrum, due to the reaction process and acid etching process, the content of Cu and Co elements are all lost, so the atomic percent content ratio of Cu and Co in the final catalyst is different from the feed ratio), and it is prepared by the following steps:

[0057] (1) Preparation of Cu-CoNCNs catalyst precursor

[0058] Under continuous stirring, dissolve 1 mmol of folic acid into a 100 ml round-bottomed flask filled with 30 ml of ultrapure water, adjust the pH of the solution to 7 with 0.1 M NaOH at room temperature, and then add 0.9 mmol of CoCl to the above solution 2 ·6H 2 O particles and 0.1 mmol of Cu(NO 3 ) 2 ·3H 2 O. After dissolving evenly, place the round bottom flask in a 60°C oil bath and react for 30 minutes. After cooling to room t...

Embodiment 2

[0068]A kind of Cu-CoNCNs catalyst derived from folic acid, when reacting feed intake, the molar percentage content of Cu is 20% (calculation formula is n Cu / (n Cu +n Co ), the same below), the molar percentage content of Co is 80% (the calculation formula is n Co / (n Cu +n Co ), the same below), prepared by the following steps:

[0069] (1) Preparation of Cu-CoNCNs catalyst precursor

[0070] Under continuous stirring, dissolve 1 mmol of folic acid into a 100 ml round bottom flask filled with 30 ml of ultrapure water, adjust the pH of the solution to 7 with 0.1 M NaOH at room temperature, and then add 0.8 mmol of CoCl to the above solution 2 ·6H 2 O particles and 0.2 mmol of Cu(NO 3 ) 2 ·3H 2 O. After dissolving evenly, place the round bottom flask in a 60°C oil bath and react for 30 minutes. After cooling to room temperature, centrifuge at a speed of 5000r / min for 3min, wash with anhydrous methanol 2 to 3 times, and dry the precipitate in a vacuum oven at 60°C fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com