Method for connecting railway through ground wire

A technology for railways to penetrate ground wires and ground wires. It is applied in the direction of circuits, connections, line/collector components, etc. It can solve the problems of increasing production costs and waste of manufacturing enterprises, so as to save manufacturing costs, digest short cables, The effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

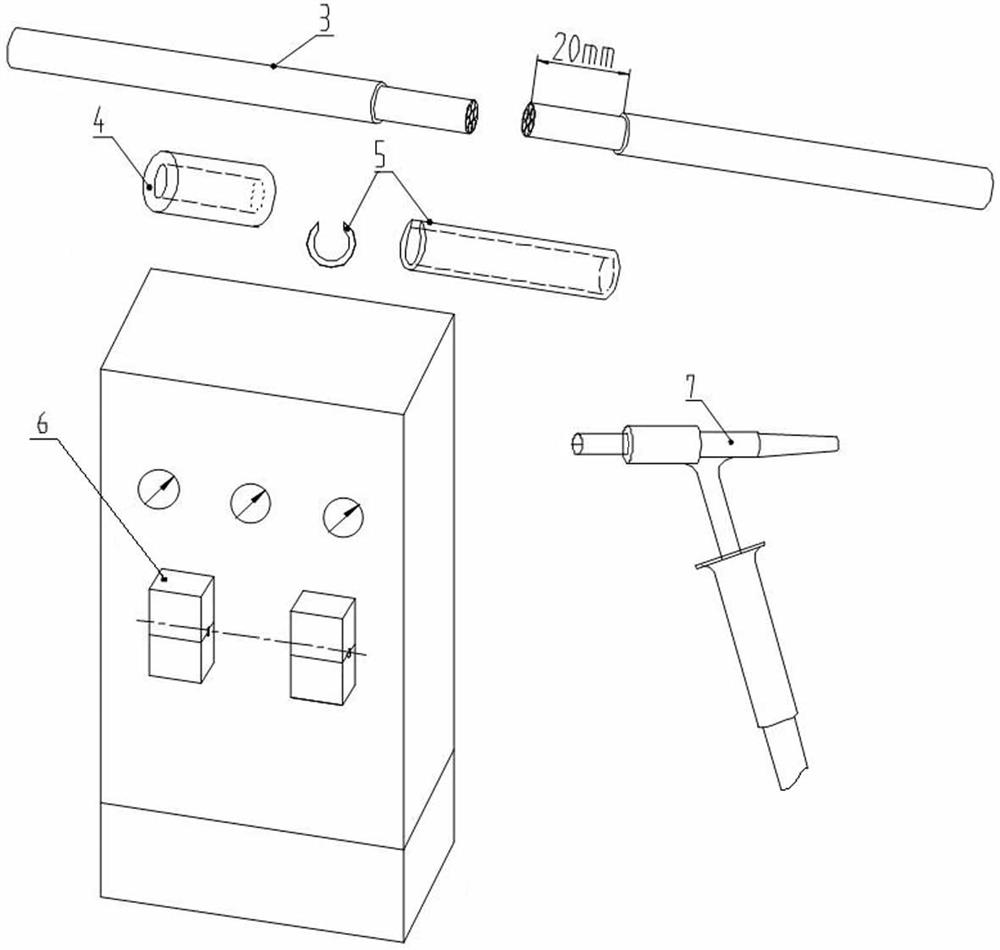

[0028] A method for connecting railway through ground wire, step 1: preparatory work (as attached figure 2 shown)

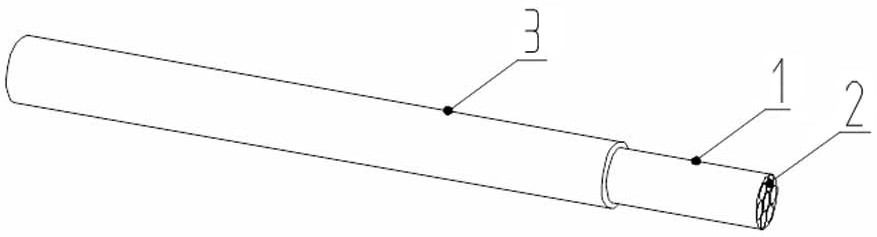

[0029] 1) Remove about 20mm of the sheath 3 at the ends of the two through-ground wires that need to be connected;

[0030] 2) Prepare the porcelain sleeve 4 for welding and connecting the pure copper conductor 2 (magnetic tube butt welding machine);

[0031] 3) Prepare the open brass sleeve 5, the opening size is slightly larger than the diameter of the cable core 1, and the maximum width of the brass sleeve 5 when unfolded is slightly smaller than the outer diameter of the metal sheath, leaving enough welding margin;

[0032] 4) Prepare the electrode clamping mold 6 of the magnetic tube butt welding machine;

[0033] 5) Prepare the handheld argon arc welding machine 7.

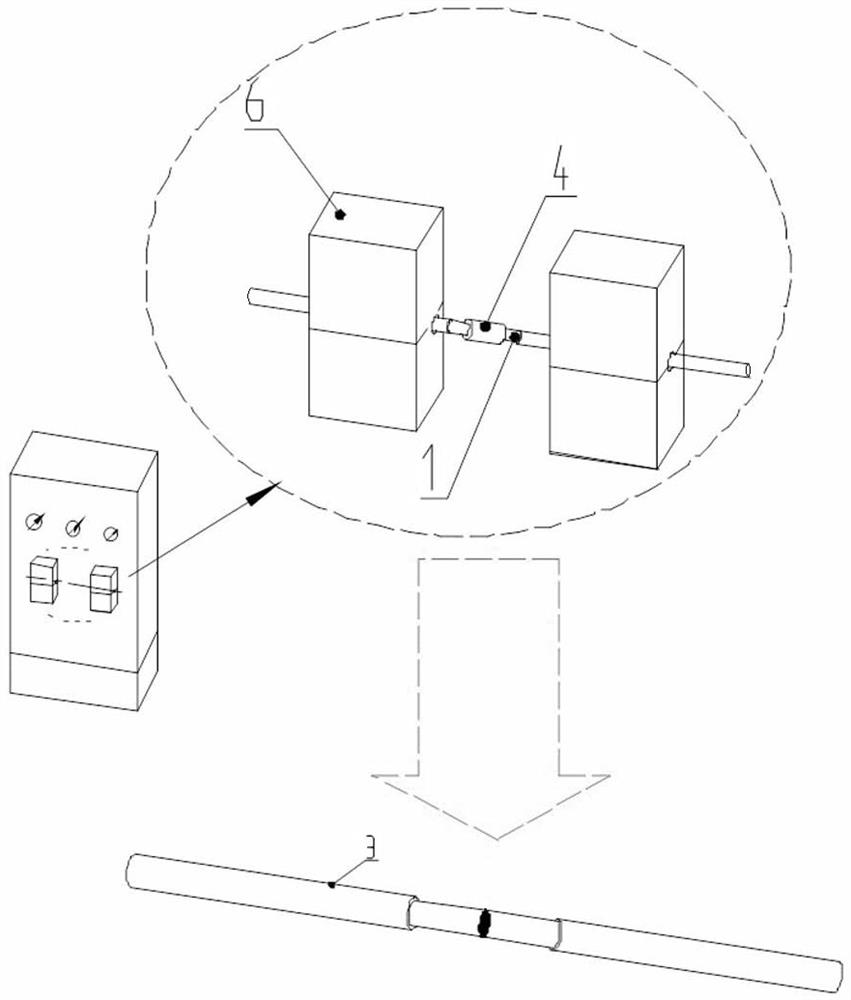

[0034] Step 2: Welding connection of the cable core (as attached image 3 shown)

[0035] 1) Put the porcelain sleeve 4 on the cable core 1 from which the sheath 3 has been removed, clamp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com