Cement electric heating composite template non-corrosive liquid heat-conducting medium and heat preservation control device

A composite formwork, heat transfer medium technology, applied in manufacturing tools, ceramic molding machines, etc., can solve the problems of wasting manpower management costs, electricity and energy, unable to dynamically control the cement hydration process, affecting the quality of concrete hardening and hardening, and reduce manual operations. , the effect of saving manpower and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

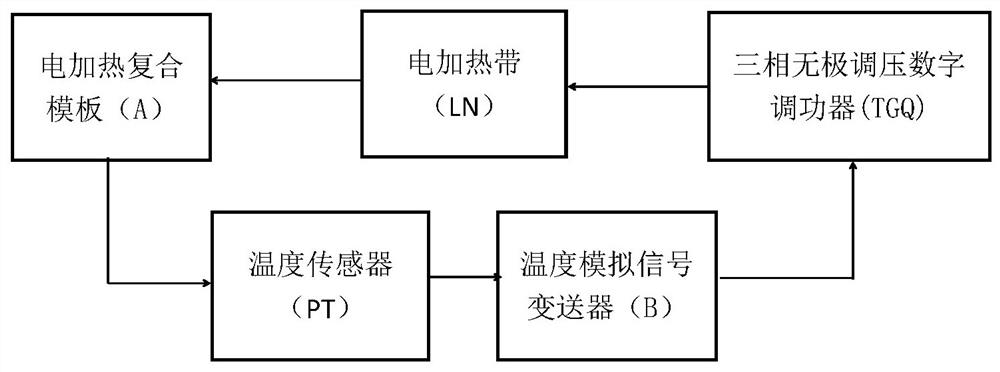

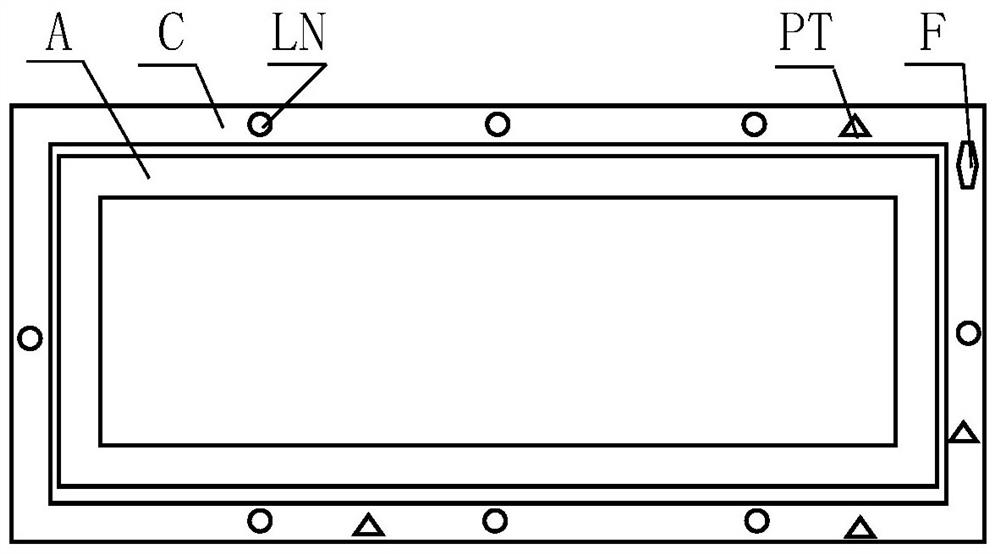

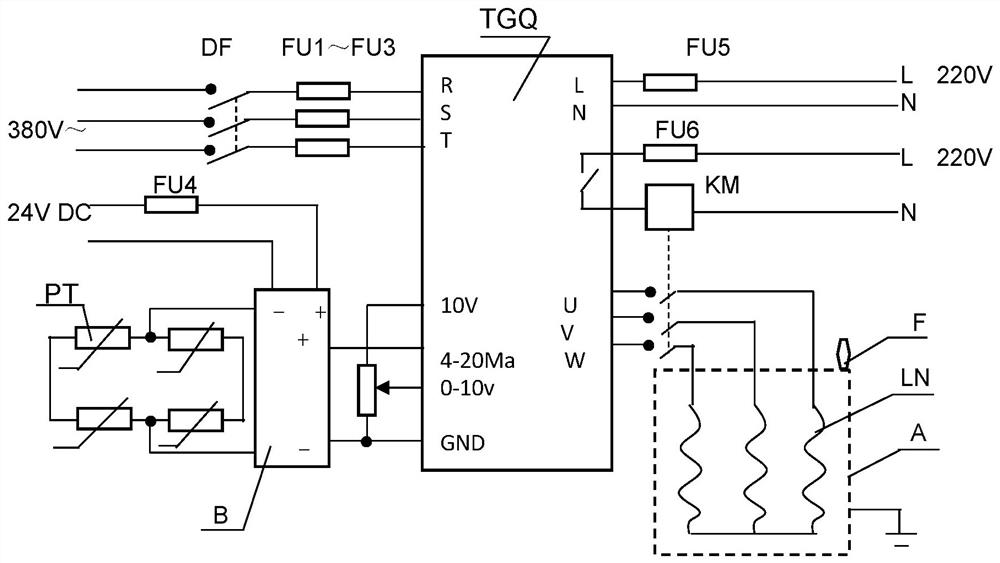

[0028] The invention provides a non-corrosive liquid heat-conducting medium of a cement electric heating composite template, and its practical application can be as follows: figure 2 As shown, the non-corrosive liquid conductive medium configured by this formula is added into the cavity of the steel electric heating composite template A, and it has no corrosion effect on the steel plate under the premise of ensuring uniform heat transfer. A formula of the non-corrosive liquid heat-conducting medium of the above-mentioned cement electric heating composite template is formed by stirring sodium molybdate, disodium hydrogen phosphate and water, and the weight ratio of sodium molybdate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com