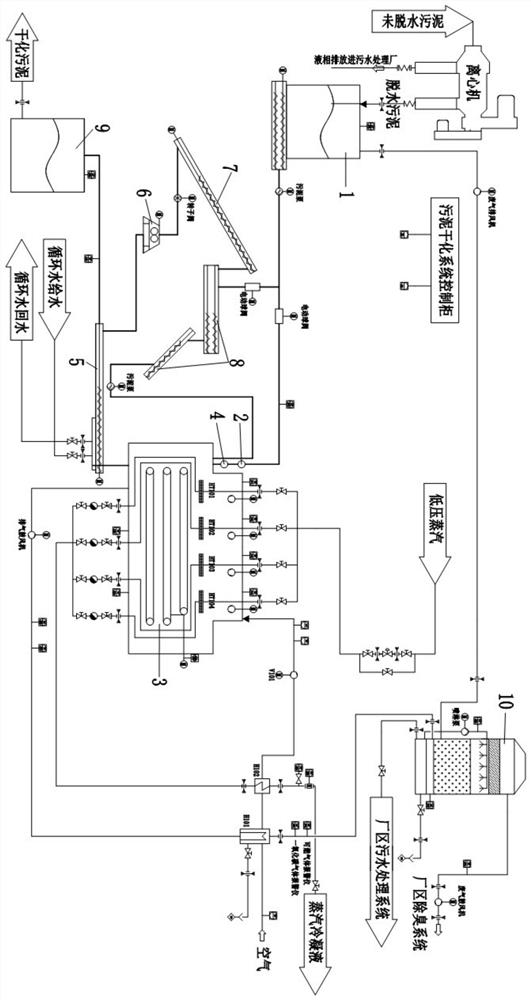

Sludge drying treatment system for water conservancy and hydropower engineering and operation method thereof

A sludge drying, water conservancy and hydropower technology, applied in the direction of water/sludge/sewage treatment, sludge treatment, water/sewage treatment, etc., can solve the problems of inconvenient sewage filtration and purification, sewage impurities, turbidity, etc. The height of the canopy is convenient for blocking rain and the effect of adjusting the height of the canopy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

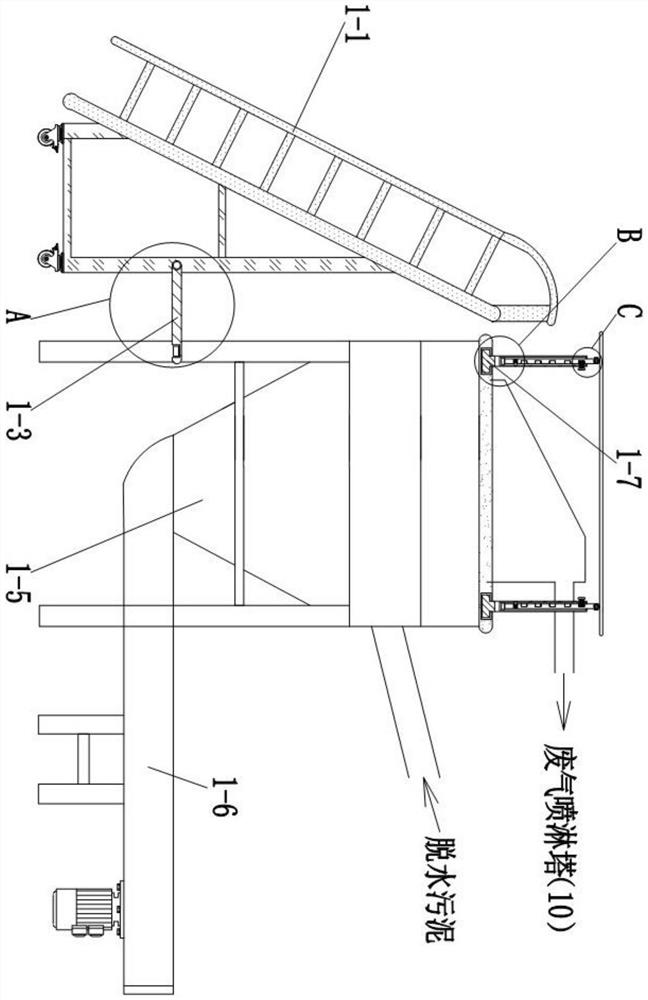

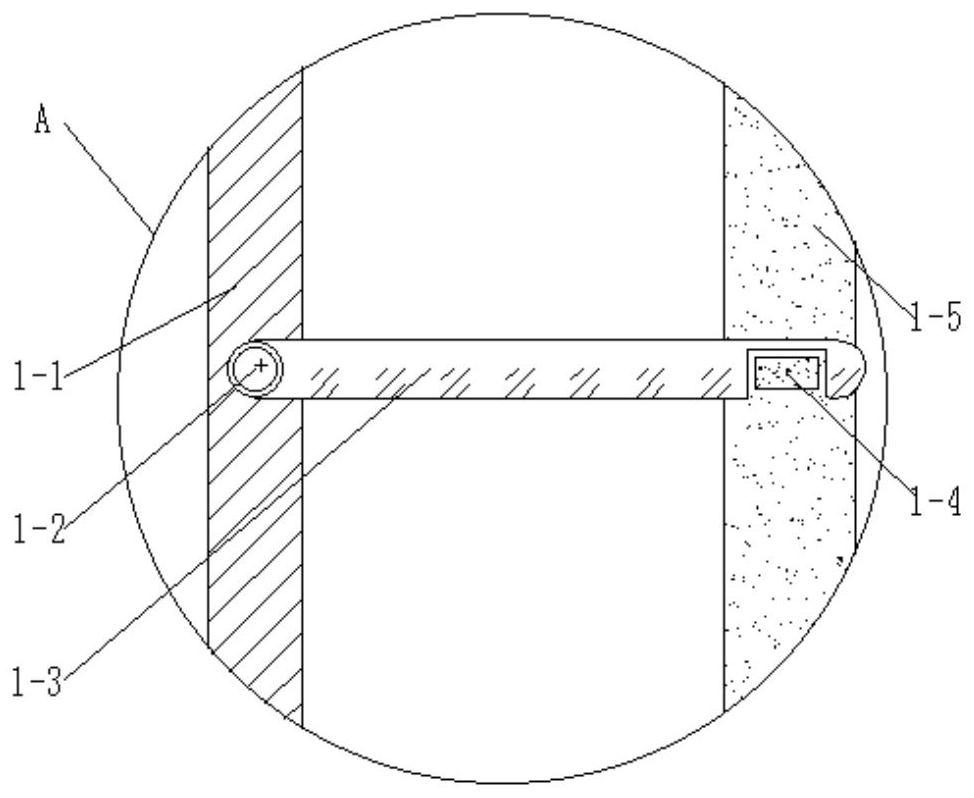

[0073] Wet sludge silo 1 with double-axis screw conveyor at the bottom, including ladder frame 1-1, rotating shaft 1-2, rotating rod 1-3, buckle block 1-4, body 1-5, and double-axis screw conveyor 1-6, card block 1-7, fixed rod 1-8, bullet block 1-9, spring 1-10, inner rod 1-11, limit block 1-12, adjustment bolt 1-13, card bolt 1- 14. The inserting block 1-15 and the canopy 1-16 are connected with a rotating shaft 1-2 on the surface of the ladder frame 1-1.

[0074] One end of the rotating shaft 1-2 is connected with a rotating rod 1-3, and one end of the rotating rod 1-3 is connected with a buckle 1-4. There is a groove at one end of the shaft, the size of the inner wall of the groove at one end of the buckle block 1-4 and the rotating rod 1-3 coincides with each other, and the rotating shaft 1-2 forms a rotating engagement through the joint of the rotating rod 1-3 and the buckle block 1-4 structure, it is convenient to fix the ladder frame 1-1 and the body 1-5, so that it i...

Embodiment 2

[0077] Mud distribution device 2, including foot pad 2-1, bearing 2-2, threaded rod 2-3, support rod 2-4, feeder 2-5, fixed block 2-6, inserting 2-7, the first Spring 2-8, limit block 2-9, buckle 2-10, cover plate 2-11, rotating shaft 2-12, body 2-13, connecting block 2-14, second spring 2-15, pressing block 2 -16 and the manipulator 2-17, the top of the foot pad 2-1 is connected with a bearing 2-2, the inner wall of the bearing 2-2 is welded with a threaded rod 2-3, the outer wall of the threaded rod 2-3 is a threaded structure, and the threaded rod 2-3 forms a rotational connection between the bearing 2-2 and the foot pad 2-1, and forms a threaded connection between the threaded rod 2-3 and the support rod 2-4. By rotating the threaded rod 2-3, the device can be The height of the feeder 2-5 is adjusted, the threaded rod 2-3 is connected through the inside of the support rod 2-4, the top of the support rod 2-4 is welded with the feeder 2-5, and the feeder 2-5 The surface of ...

Embodiment 3

[0080] The sludge noodle forming machine 4 includes a body 4-1, a fixed rod 4-2, a threaded rod 4-3, a rotating block 4-4, a connecting column 4-5, a clamping block 4-6, a scraper 4-7, Transmission belt 4-8, mounting plate 4-9, connecting block 4-10, rotating shaft 4-11, movable rod 4-12, mounting block 4-13, docking block 4-14, spring 4-15 and linkage block 4 -16, the bottom of the body 4-1 is connected with a fixed rod 4-2.

[0081] The fixed rod 4-2 is provided with a threaded rod 4-3 inside, and the threaded rod 4-3 is vertically connected to the inside of the connecting column 4-5, and the size of the outer wall of the threaded rod 4-3 matches the size of the inner wall of the connecting column 4-5, and The connection between the threaded rod 4-3 and the connecting column 4-5 forms a threaded connection structure, which plays a role in making the connecting column 4-5 move under the rotation of the threaded rod 4-3, and the bottom of the threaded rod 4-3 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com