Preparation method of light flexible isolation type elastomer composite microporous strain sensing material

A technology of strain sensing and thermoplastic elastomers, applied in the measurement of the property force of piezoelectric resistance materials, electric/magnetic solid deformation measurement, electromagnetic measurement devices, etc., can solve the problems affecting the machinability and mechanical properties of composite materials, etc. problem, achieve the effect of reducing the conductive percolation threshold, the preparation method is simple and efficient, and the molding processability is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention discloses a method for preparing a lightweight, flexible isolation type elastomer composite microporous strain sensing material, which specifically includes the following steps:

[0025] In step 1, the thermoplastic elastomer beads are placed in a supercritical CO 2 Carry out saturated absorption in an autoclave for 3 to 6 hours. The saturation temperature is 35 to 60°C and the saturation pressure is 8 to 16 MPa. Then, place the fully saturated thermoplastic elastomer beads in a high temperature foaming device (oil bath, heating kettle and oven) etc.) for microcellular foaming, the foaming temperature is 100-130°C, and the foaming time is 45-100s to obtain thermoplastic elastomer microcellular foamed beads with different expansion ratios;

[0026] Thermoplastic elastomers include thermoplastic nylon elastomer (TPAE), thermoplastic polyurethane elastomer (TPU), thermoplastic polyester elastomer (TPEE), thermoplastic polyolefin elastomer (TPO), etc., accordi...

Embodiment 1

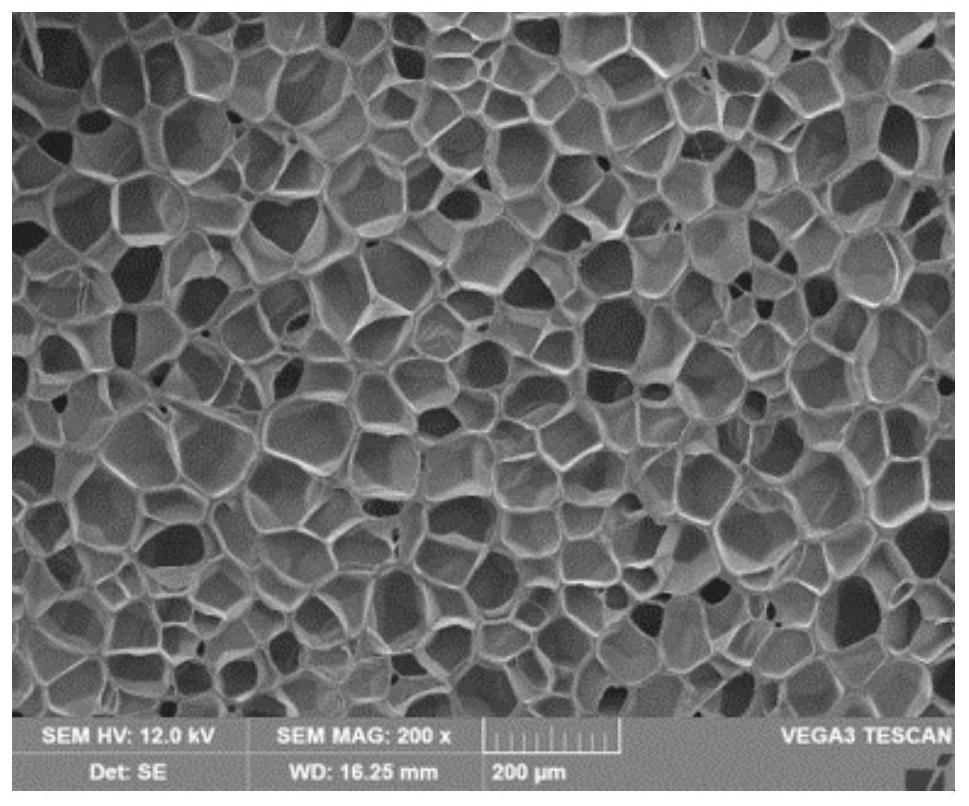

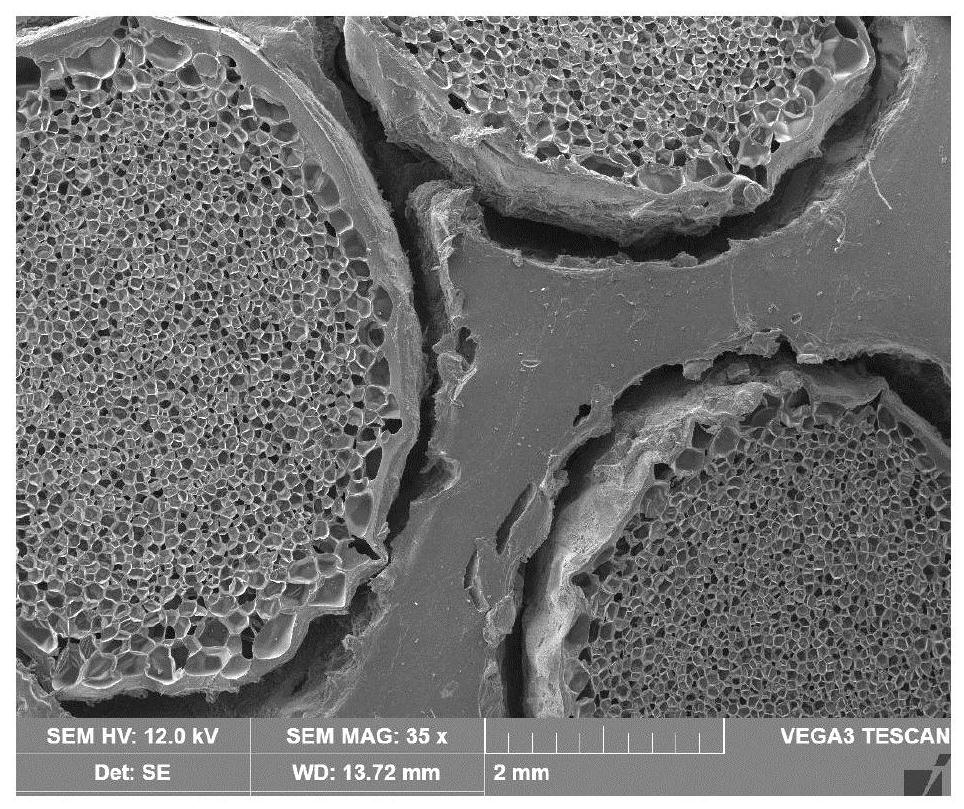

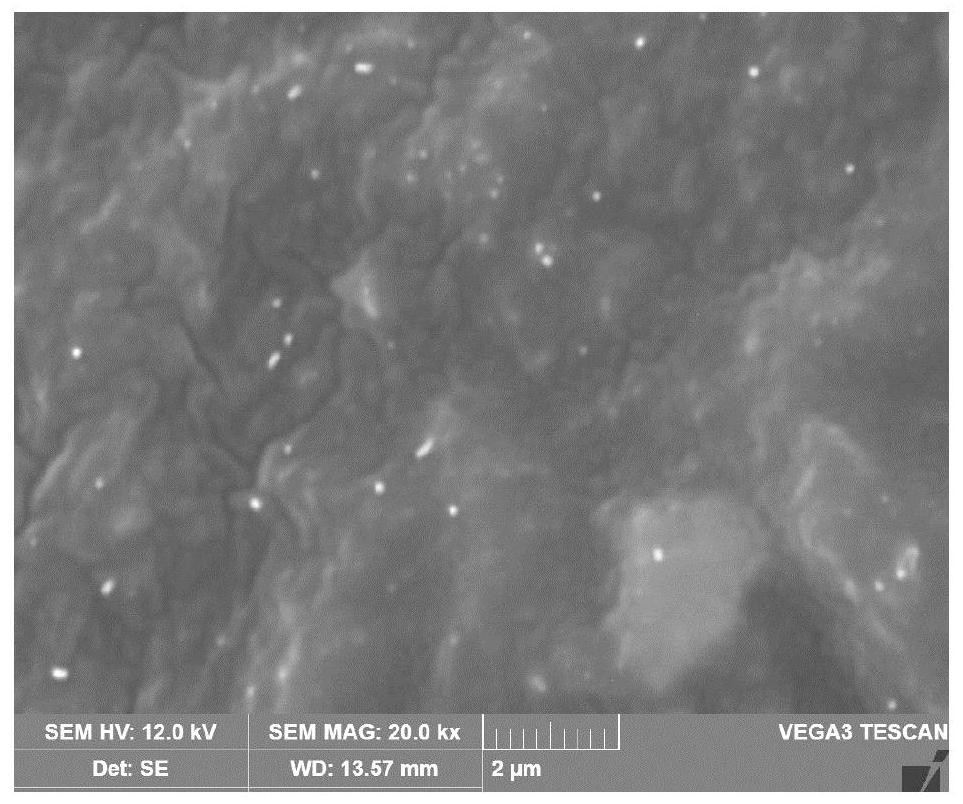

[0033] Nylon 66 thermoplastic elastomer beads were placed in an autoclave, heated and fed with supercritical CO 2 fluid, the saturation temperature is 35°C, the saturation pressure is 8MPa, the saturation time is 3h, and then the nylon 66 thermoplastic elastomer beads / CO 2 The mixed material was transferred to a constant temperature silicone oil bath for foaming. The foaming temperature was 100°C, and the foaming time was 45s. Finally, it was placed at room temperature to cool and shape to obtain nylon 66 thermoplastic elastomer microcellular foamed beads. The conductive silver (Ag) paste was wrapped on the surface of thermoplastic elastomer microporous foamed beads by dip coating method, and dried at room temperature to obtain silver-coated nylon 66 thermoplastic elastomer microporous foamed beads; MWCNTs were dispersed in PDMS In the preform solution, ultrasonically stirred for 30 minutes, and then placed in a constant temperature oven at 60°C to remove the solvent to obtain...

Embodiment 2

[0035] Nylon 66 thermoplastic elastomer beads were placed in an autoclave, heated and fed with supercritical CO 2 Fluid, the saturation temperature is 38°C, the saturation pressure is 10MPa, the saturation time is 3h, and then the nylon 66 thermoplastic elastomer beads / CO 2 The mixed material was transferred to a constant temperature silicone oil bath for foaming. The foaming temperature was 100°C, and the foaming time was 80s. Finally, it was placed at room temperature to cool and shape to obtain nylon 66 thermoplastic elastomer microcellular foamed beads. The conductive silver (Ag) slurry was wrapped on the surface of nylon 66 thermoplastic elastomer microcellular foamed beads by dip coating method, and dried at room temperature to obtain silver-coated nylon 66 thermoplastic elastomer microcellular foamed beads; the MWCNTs Dispersed in the PDMS preform solution, stirred ultrasonically for 45min, and then placed in a constant temperature oven at 80°C to remove the solvent to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com