Self-exhausting OCA optical adhesive as well as preparation method and application thereof

A self-venting, optical adhesive technology, applied in the field of optical adhesive, can solve the problems of complex production process, high equipment performance requirements, affecting production efficiency, etc., and achieve the effect of improving yield, improving mechanical properties, and improving filling capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

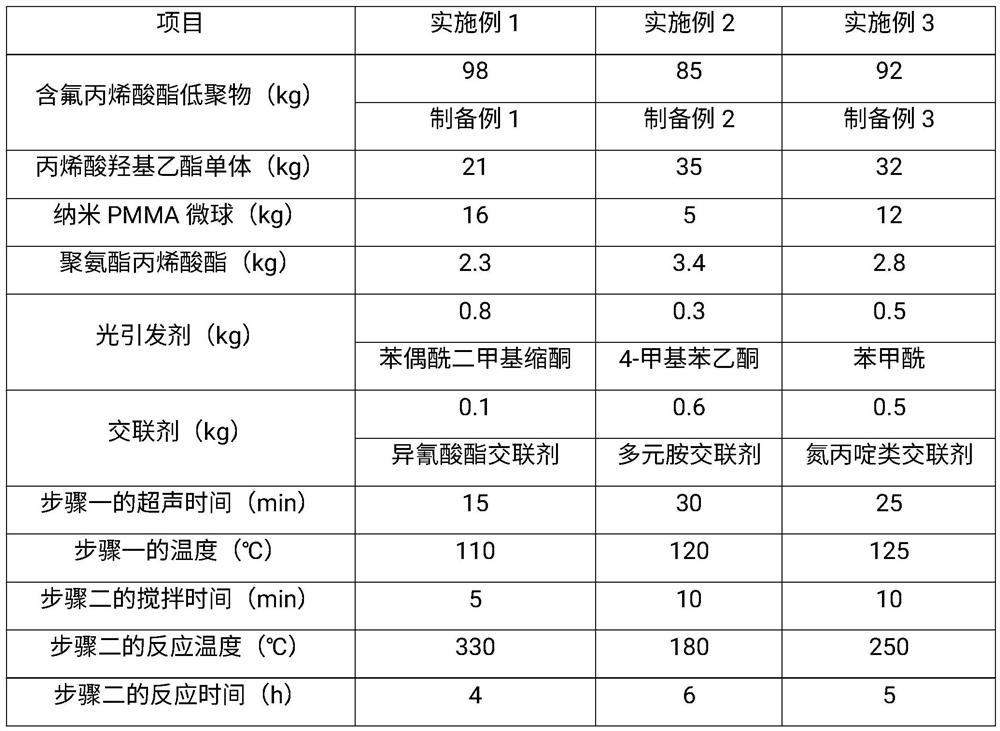

Examples

preparation example 1-3

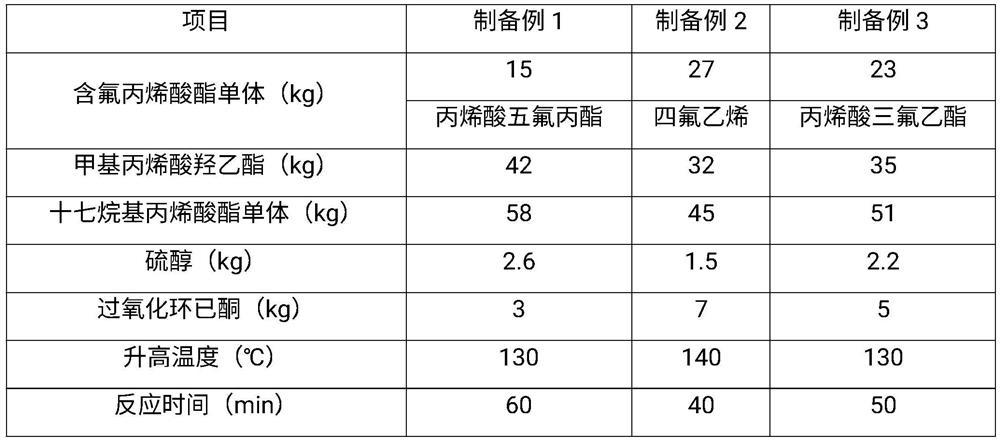

[0047]A fluorine-containing acrylate oligomer, which is prepared by the following steps: Weigh fluorine-containing acrylate monomer, hydroxyethyl methacrylate and heptadecyl acrylate monomer into a container, and pass nitrogen gas to provide protection , the temperature is raised to the temperature shown in Table 2, after constant temperature, mercaptan and cyclohexanone peroxide are added dropwise in turn, and the reaction time is referred to Table 2, and the fluorine-containing acrylate oligomer is obtained.

[0048] Each component content and process parameter in the table 2-preparation example 1-3

[0049]

preparation example 4

[0051] A modified urethane acrylate, which is prepared by the following steps: put urethane acrylate weighing 53kg into a container, blow nitrogen into it, heat to a temperature of 70°C, and place 26kg of amino polysiloxane one by one Add it dropwise into the container and keep it warm for 4.5 hours to obtain the modified polyurethane acrylate.

preparation example 5

[0053] A modified urethane acrylate is prepared by the following steps: put urethane acrylate weighing 67kg into a container, blow nitrogen into it, heat to a temperature of 85°C, and place 38kg of aminopolysiloxane one by one Add it dropwise into the container and keep it warm for 3.5 hours to obtain the modified polyurethane acrylate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com