Ternary positive electrode material of lithium ion battery, preparation method of ternary positive electrode material and lithium ion battery

A technology for lithium-ion batteries and positive electrode materials, applied in the direction of battery electrodes, positive electrodes, electrical components, etc., to achieve good mechanical strength, facilitate the insertion/extraction process, and high capacity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] a. Choose n 镍 :n 钴 :n 锰 =0.8:0.1:0.1 ratio, using nickel sulfate, cobalt sulfate, and manganese sulfate as raw materials to make a mixed solution with a total metal ion concentration of 2mol / L; configure 2mol / L NaOH solution as a precipitant; configure 2mol / L ammonia water as a complexing agent.

[0052] b. Take the mixed metal ion solution as the mother liquor, add sodium hydroxide solution and ammonia solution to it at a certain speed, control the pH of the reaction system to be 10.5 by adjusting the valve and flow meter, the reaction temperature is 55°C, the reaction time is 18h, and the stirring speed The temperature is 300r / min. After the reaction is completed, the solid-liquid separation of the feed liquid is carried out, and the collected solid product is dried at 80°C for 24h, and the particle size of the obtained precursor is 3800nm.

[0053] c. Use lithium hydroxide as the lithium source, mix with the dried precursor according to the lithiation ratio of 1.0...

Embodiment 2

[0057]The method of Example 1 was used to prepare the ternary positive electrode material, the only difference being that in step b, the pH of the reaction system was controlled to be 10.2, the reaction temperature was 50°C, the reaction time was 14h, the stirring speed was 350r / min, and the collected solid The product was dried at 100° C. for 15 h, and the particle size of the obtained precursor was 1600 nm.

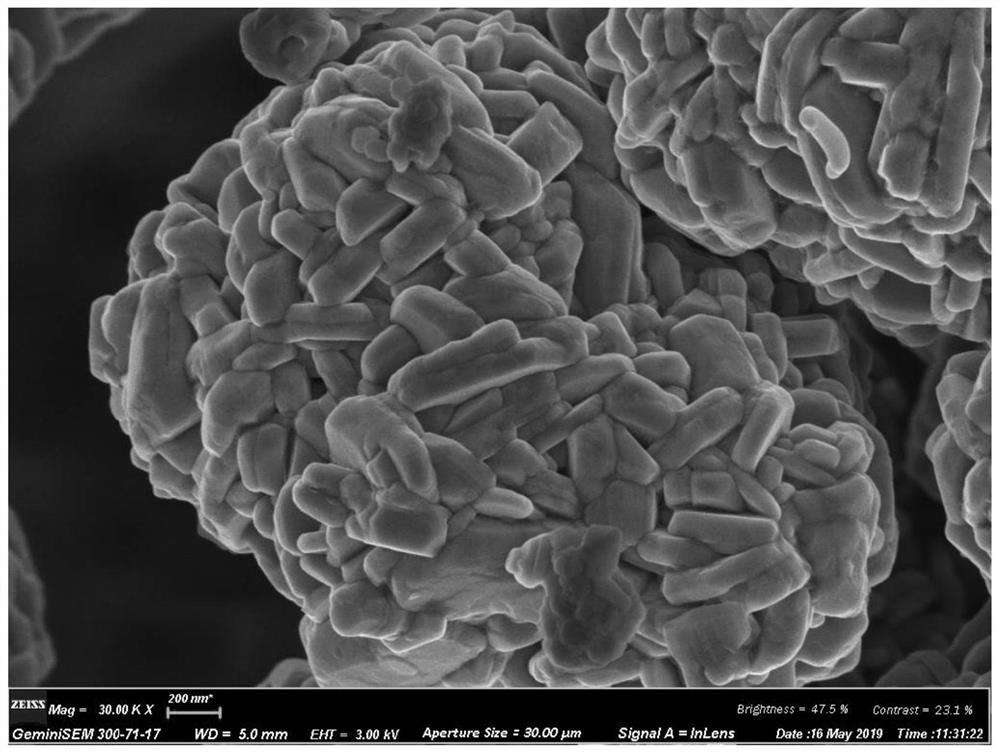

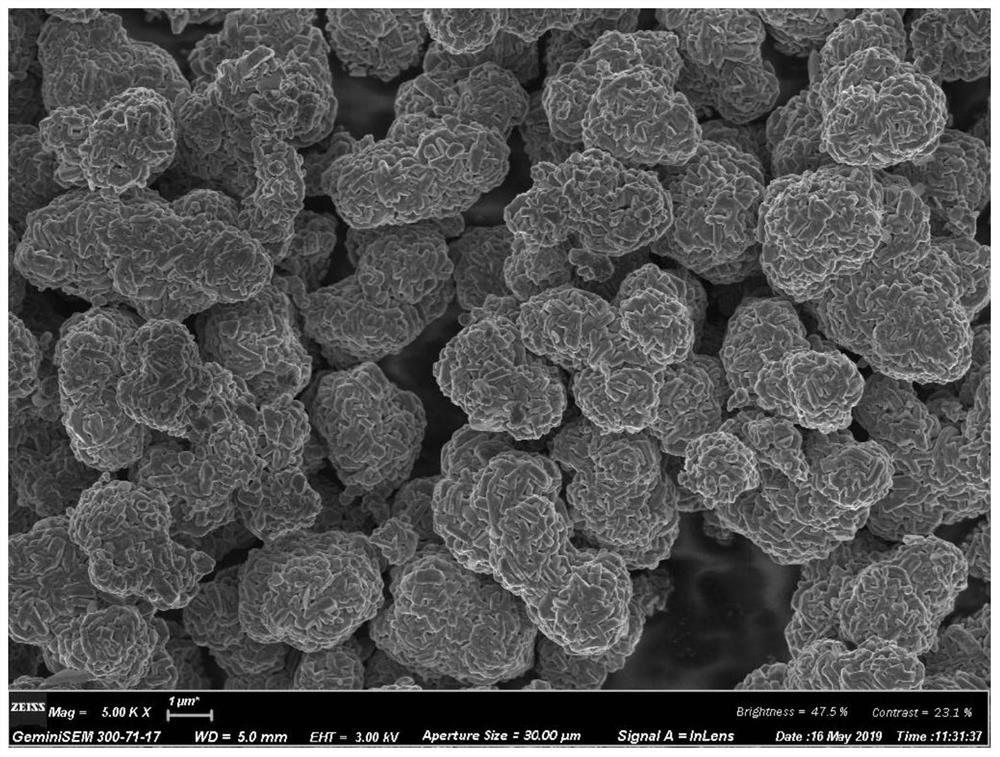

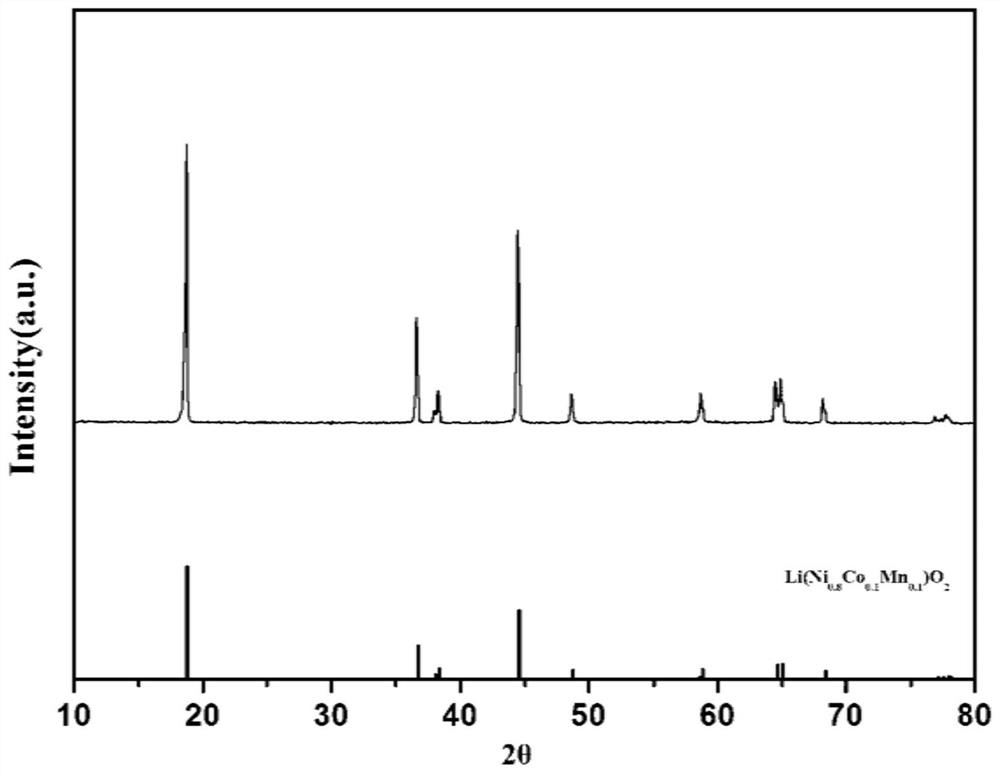

[0058] The test results show that the phase of the prepared sample is Li(Ni 0.8 co 0.1 mn 0.1 )O 2 , the additives used did not affect the sintering process of the ternary cathode material, and the product was still a nickel-cobalt lithium manganate ternary cathode material. The scanning electron microscope results showed that the sample had a hierarchical lamellar structure, and the thickness was 120nm, and the length was 330nm. Assembled by layers, Bi 2 o 3 and V 2 o 5 The introduction of the ternary material maintains the lamellar stacking morphology of the pr...

Embodiment 3

[0060] The method of Example 1 was used to prepare the ternary positive electrode material, the only difference being that in step b, the pH of the reaction system was controlled to be 10.7, the reaction temperature was 55°C, the reaction time was 24h, the stirring speed was 280r / min, and the collected solid The product was dried at 90° C. for 30 h, and the particle size of the obtained precursor was 6200 nm.

[0061] The test results show that the phase of the prepared sample is Li(Ni 0.8 co 0.1 mn 0.1 )O 2 , the additives used did not affect the sintering process of the ternary cathode material, and the product was still a nickel-cobalt lithium manganate ternary cathode material. The scanning electron microscope results showed that the sample had a hierarchical lamellar structure, and the thickness was 180nm, and the length was 540nm. Assembled by layers, Bi 2 o 3 and V 2 o 5 The introduction of the ternary material maintains the lamellar stacking morphology of the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com