Composition for thick film resistor, paste for thick film resistor, and thick film resistor

A technology of thick film resistors and components, applied in thick film resistors, resistors, resistor manufacturing, etc., can solve the characteristics of unstable resistance value and temperature coefficient of resistance, large resistor body current noise, and inability to obtain load characteristics, etc. problem, to achieve good temperature coefficient of resistance and noise characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0127] Hereinafter, specific examples and comparative examples are given and described, but the present invention is not limited to these examples.

[0128] (Evaluation method)

[0129] First, evaluation methods in the following examples will be described.

[0130] 1. Evaluation of ruthenium oxide powder

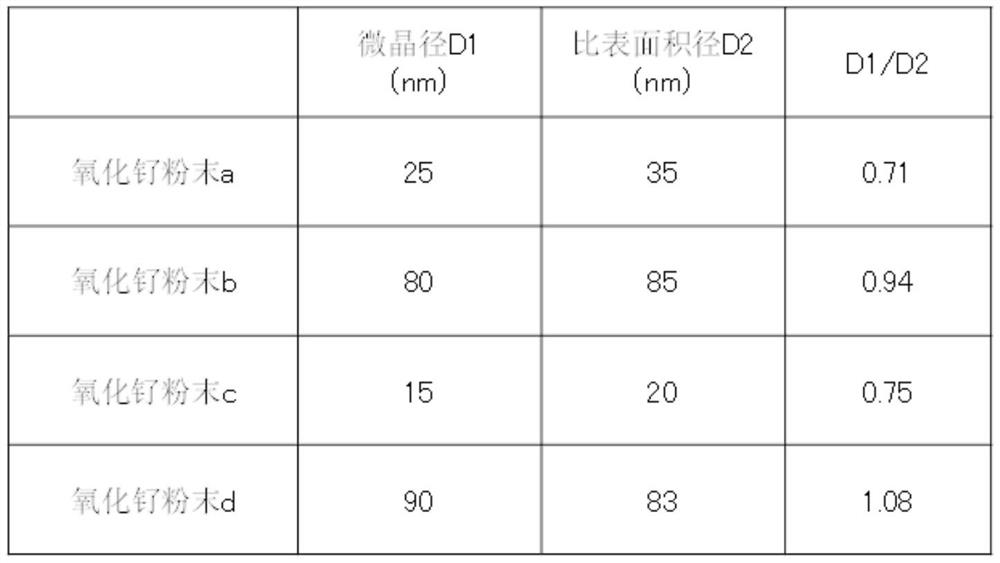

[0131] The crystallite diameter D1 and specific surface area diameter D2 of ruthenium oxide powder a to ruthenium oxide powder d used in the following examples were evaluated. The evaluation results are shown in Table 1.

[0132] (1) Crystalline diameter

[0133] The crystallite diameter can be calculated from the peak spread of the X-ray diffraction pattern. Here, after the peak waveform of the rutile structure obtained by X-ray diffraction is separated into Kα1 and Kα2, the full width at half maximum value is measured as the peak spread of Kα1 corrected for the spread caused by the optical system of the measurement equipment, And calculated according to the Scherrer f...

experiment example 1

[0170] (Preparation of composition for thick film resistors)

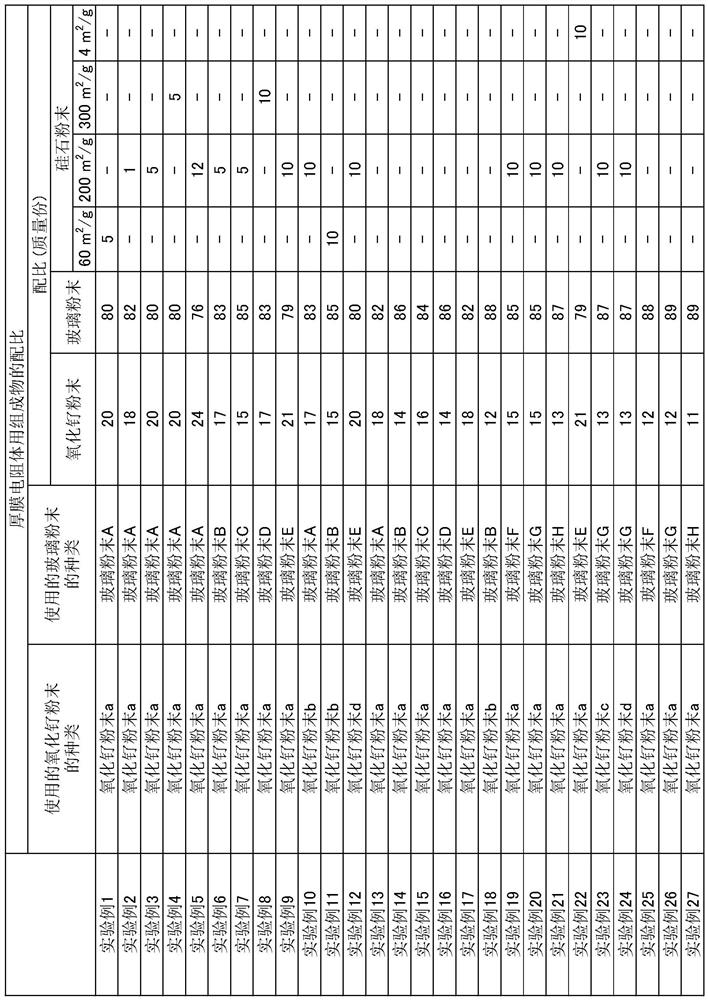

[0171] In Experimental Example 1, as shown in Table 3, 20 parts by mass of ruthenium oxide powder a, 80 parts by mass of glass powder A, and 5 parts by mass of silica powder were mixed to prepare a composition for a thick film resistor. Here, as the silica powder, as shown in Table 3, a specific surface area of 60m 2 / g of material. In addition, the ratio of ruthenium oxide particles to glass powder was adjusted so that the area resistance value of the thick film resistor was approximately 100 kΩ.

[0172] (Preparation of paste for thick film resistors)

[0173] With respect to 100 parts by mass of the total content of ruthenium oxide powder and glass powder contained in the prepared composition for thick film resistors, the organic vehicle was weighed to 43 parts by mass, and dispersed in the machine using a 3-roll mill. In the carrier, make a paste for thick film resistors.

[0174] (Manufacturing of thick ...

experiment example 2~ experiment example 27

[0179] When preparing the composition for thick film resistors, the materials shown in Table 3 were used as ruthenium oxide powder, glass powder, and silica powder, and were weighed and mixed according to the proportion shown in Table 3. In the same manner, a composition for a thick film resistor was prepared.

[0180] In addition, in the same manner as in Experimental Example 1, except for using the composition for thick film resistors prepared in each experimental example, a paste for thick film resistors and a thick film resistor were produced, and the thickness of the thick film resistor was did an evaluation. The evaluation results are shown in Table 4.

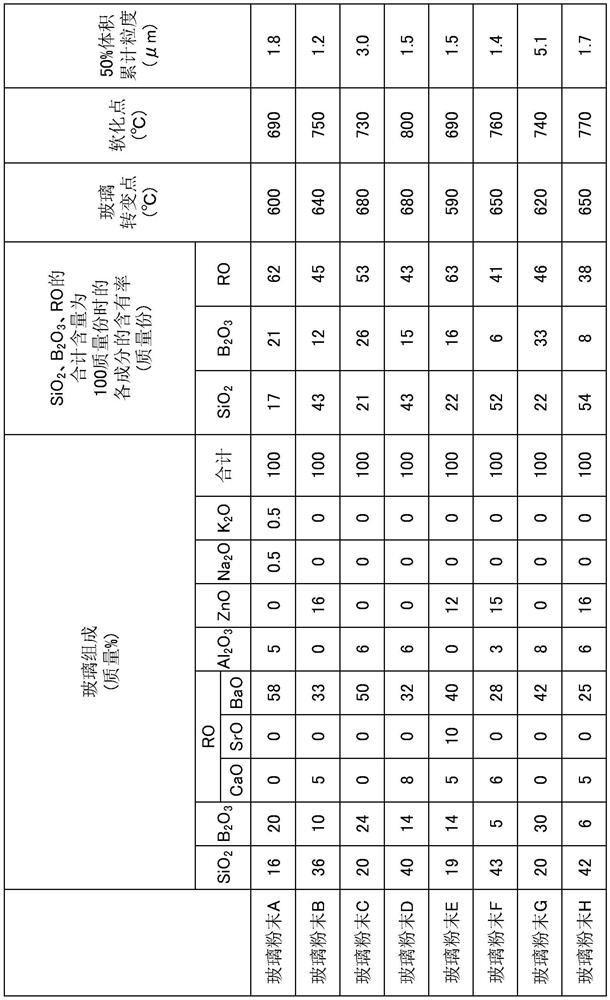

[0181] Here, the physical properties of the ruthenium oxide powder used in each of the above experimental examples are shown in Table 1, and the composition and physical properties of the glass powder are shown in Table 2. As for the silica powder, materials having specific surface areas shown in Table 3 were used, res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com