Rapid water-phase synthesis method of multifunctional cyclodextrin polymerized microspheres

A technology for polymerizing microspheres and cyclodextrins, which can be applied to inactive components of polymer compounds, microcapsules, nanocapsules, etc. The preparation method is simple, the product morphology and size are regular and uniform, and the synthesis reaction is mild.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

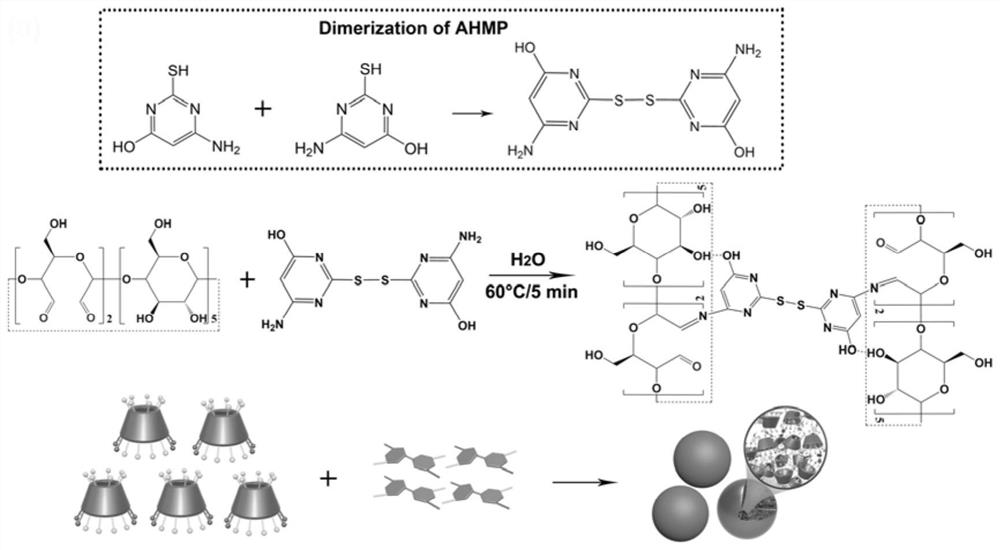

[0048] A rapid aqueous phase synthesis method of multifunctional cyclodextrin polymerized microspheres, comprising the following steps:

[0049]1) Preparation of aldehyde-cyclodextrin: Dissolve and disperse 30g of β-cyclodextrin in 200mL of deionized water, then add sodium periodate (6-18g) of different quality, stir at 40°C at constant speed and avoid light for 4h , and then filtered with a 220nm filter membrane, and the filtrate was precipitated with 800mL of excess absolute ethanol to obtain aldehyde cyclodextrins with different aldehyde content with a dialdehyde structure;

[0050] 2) washing the aldehyde cyclodextrin with a mixed solvent of ethanol / water (V / V=80 / 20), and then freeze-drying to obtain aldehyde cyclodextrin freeze-dried powders with different modification ratios;

[0051] 3) Dissolve aldehyde cyclodextrin freeze-dried powder in deionized water to prepare an aqueous solution and heat it in a water bath to 60-80°C;

[0052] 4) Add the cross-linking agent 4-am...

Embodiment 1

[0069] A rapid aqueous phase synthesis method of multifunctional cyclodextrin polymerized microspheres, comprising the following steps:

[0070] 1) Dissolve and disperse 30g of β-cyclodextrin in 200mL of deionized water, add 12g of sodium periodate, and react in the dark at 40°C for 4 hours, then filter with a 220nm filter membrane, and use 800mL of excess ethanol to filter the filtrate Precipitate and separate out, obtain aldehyde group cyclodextrin;

[0071] 2) washing the aldehyde cyclodextrin with a mixed solvent of ethanol / water (V / V=80 / 20), and then freeze-drying to obtain the aldehyde cyclodextrin freeze-dried powder;

[0072] 3) Dissolve 0.34g of aldehyde cyclodextrin freeze-dried powder in 20mL of deionized water, and heat to 60°C in a water bath;

[0073] 4) Add 0.17g of 4-amino-6-hydroxy-2-mercaptopyrimidine, the pH of the system is about 7.0 at this time, then continue to heat and stir for 5 minutes;

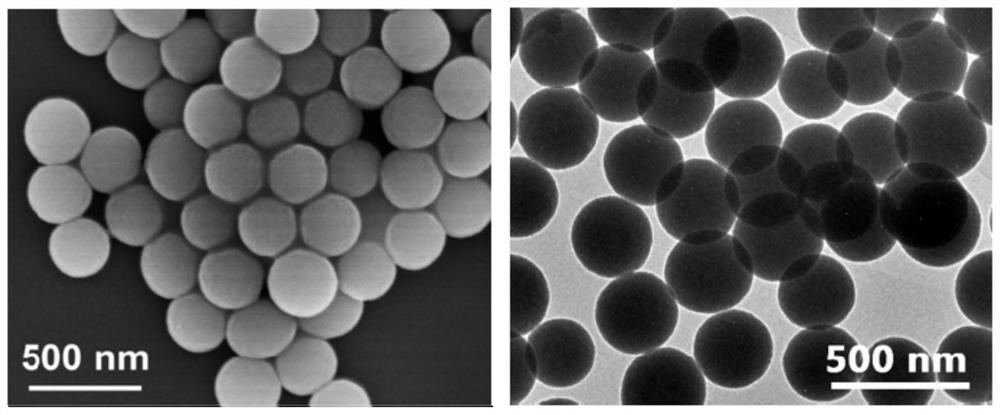

[0074] 5) After the product is washed and vacuum-dried, cyclo...

Embodiment 2

[0078] In step 4) of this example, after adding 4-amino-6-hydroxy-2-mercaptopyrimidine, adjust the pH to 7.0, 7.5, 8.0, and 8.5 respectively, and then conduct the heating reaction, and the rest are the same as in Example 1. The SEM figure and TEM figure of gained cyclodextrin polymer microsphere are as follows Figure 5 shown

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com