Grinding device, grinding machine and grinding method

A technology of a grinding device and a grinding method, which is applied in the directions of grinding devices, grinding machine tools, abrasive surface adjustment devices, etc., can solve the problem that the grinding silicon powder and the grinding wheel fallout cannot be cleaned and discharged in time, and the effect of cooling water cooling and excretion is not obvious. problems such as the grinding quality of the sheet, to achieve the effect of good surface quality and nano-morphology, improved grinding quality and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

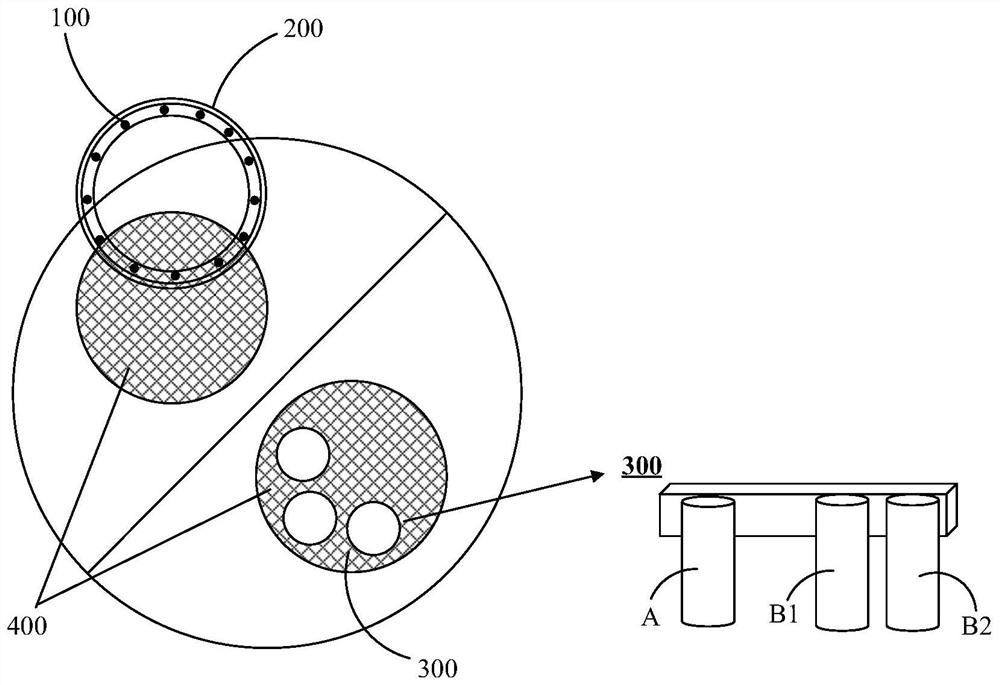

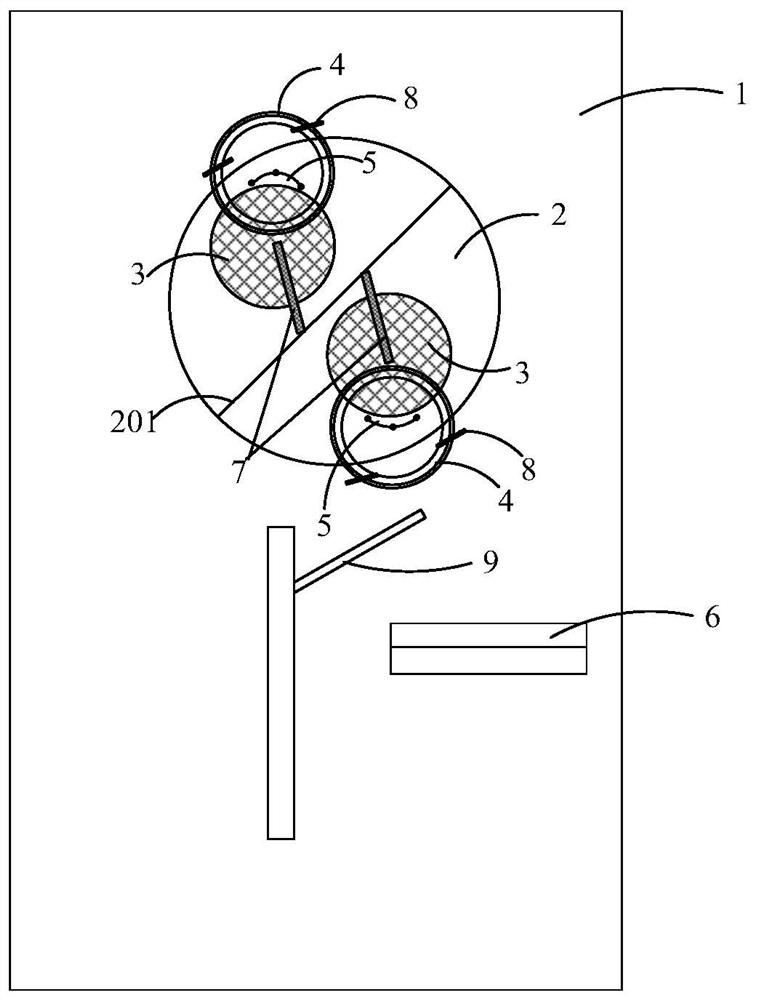

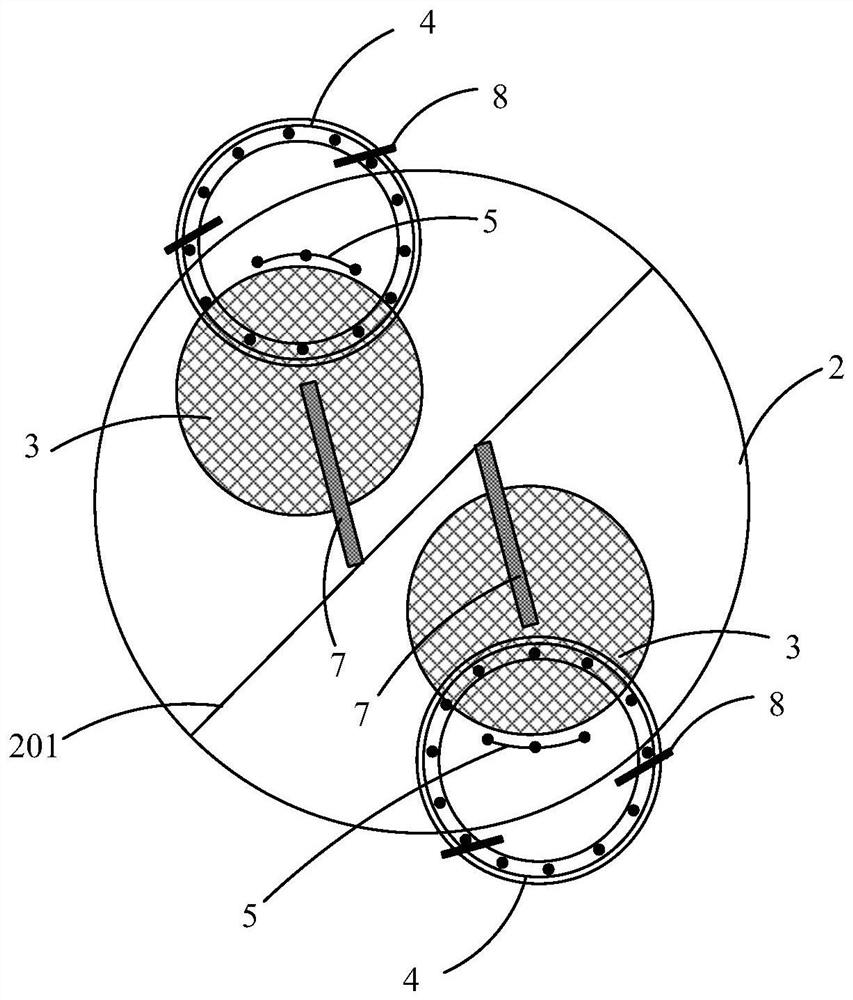

[0046] Please refer to figure 2 and image 3 , figure 2 It is a structural schematic diagram of a grinding device provided by an embodiment of the present invention; image 3 It is a structural schematic diagram of the rotary table provided by the embodiment of the present invention. As shown in the figure, the grinding device of the embodiment of the present invention includes: a workbench 1; a rotary table 2 arranged on the worktable 1; at least one vacuum chuck 3 arranged on the rotary table 2; a grinding disc 4 positioned on the vacuum chuck 3; the first cleaning device 5 is arranged on the rotary table 2 to clean and cool the grinding area of the grinding disc 4 in contact with the vacuum chuck 3; the first cleaning and drying device 6 is movably arranged on the workbench 1, to clean and dry the backside of the ground silicon wafer.

[0047] In the present embodiment, the vacuum chuck 3 is used to load silicon wafers that need to be ground, and the grinding disc 4...

Embodiment 2

[0070] The embodiment of the present invention also provides a grinding machine, which includes the grinding device as described in the first embodiment, and the grinding device has the advantages corresponding to the grinding machine, which will not be repeated here.

[0071] The embodiment of the present invention also provides a grinding method, which is suitable for the grinding machine described in the above embodiment, and the method includes:

[0072] S1: Load the silicon wafer on the vacuum chuck;

[0073] Specifically, the silicon wafer to be ground can be loaded on a vacuum chuck by a robot arm or an internal conveying device. In addition, before loading the silicon wafers to be ground, warm-up operation is performed first, that is, dry operation, so that the warm-up operation of the equipment is stable, and the second cleaning and drying device is also turned on to clean and dry the workbench.

[0074] S2: Control the grinding disc to grind the silicon wafer loaded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com