Circulating purification process and device for water pollution treatment

A cyclic purification and water pollution technology, which is applied in the fields of neutralization water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can solve the problem of real-time detection of water quality without sewage discharge and poor sewage filtration effect And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

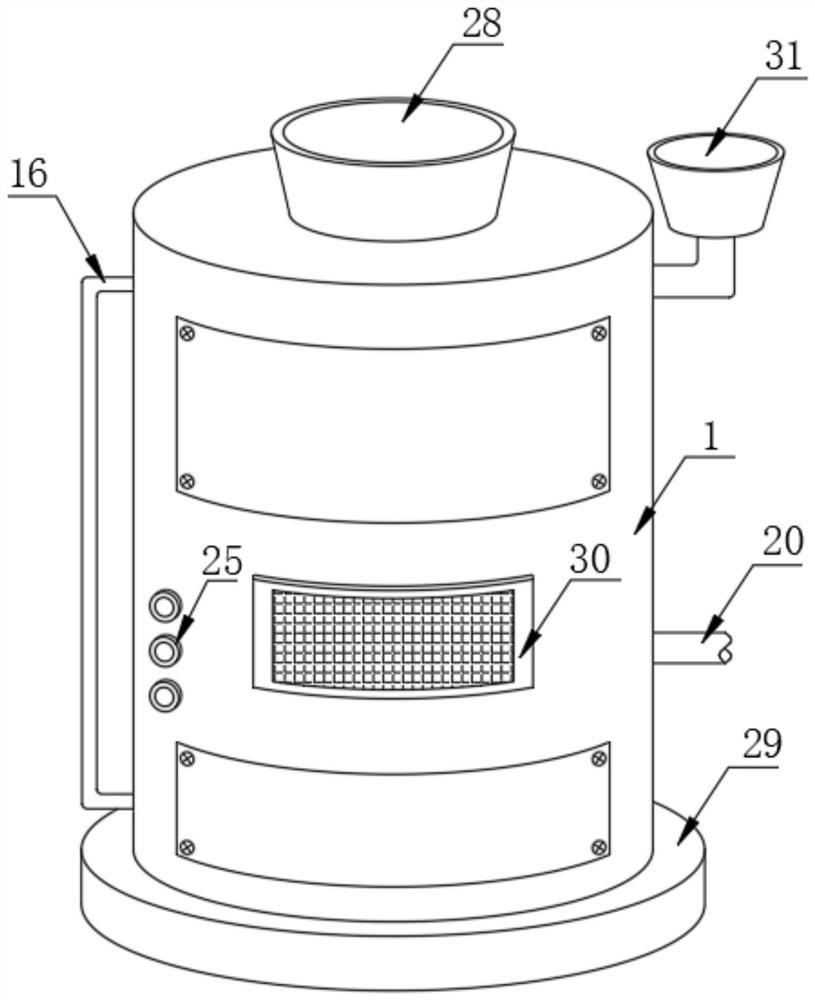

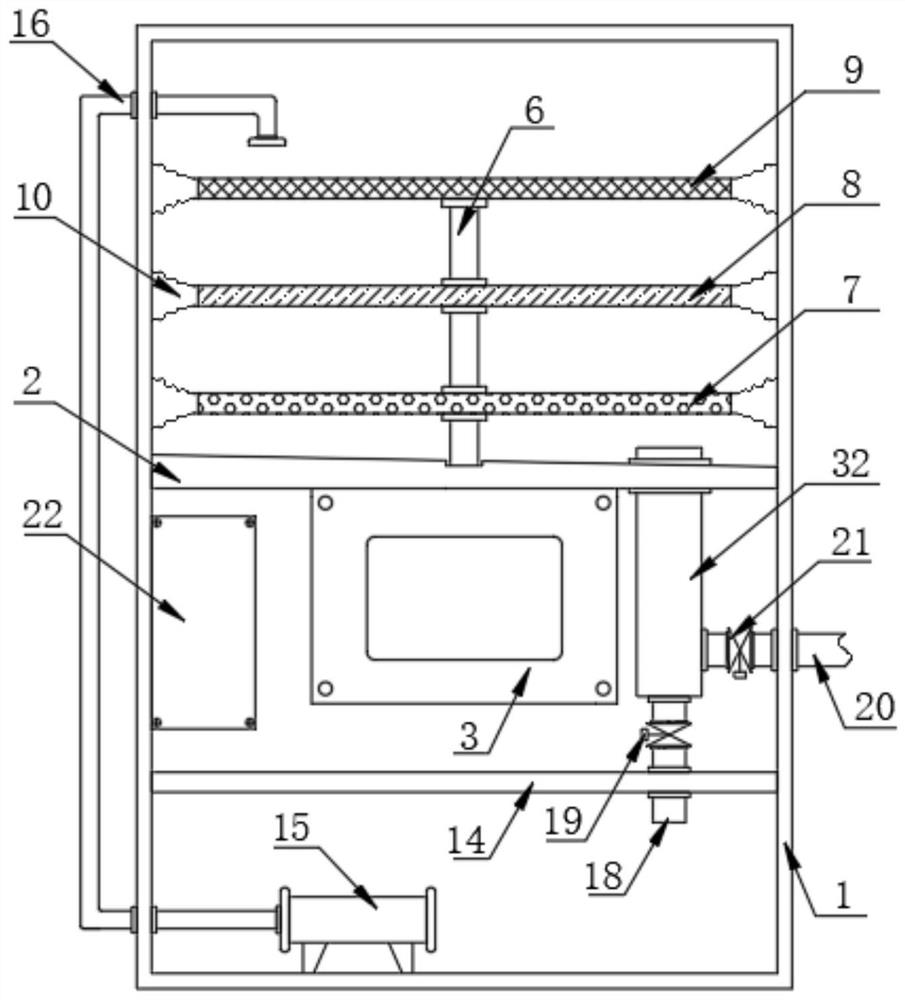

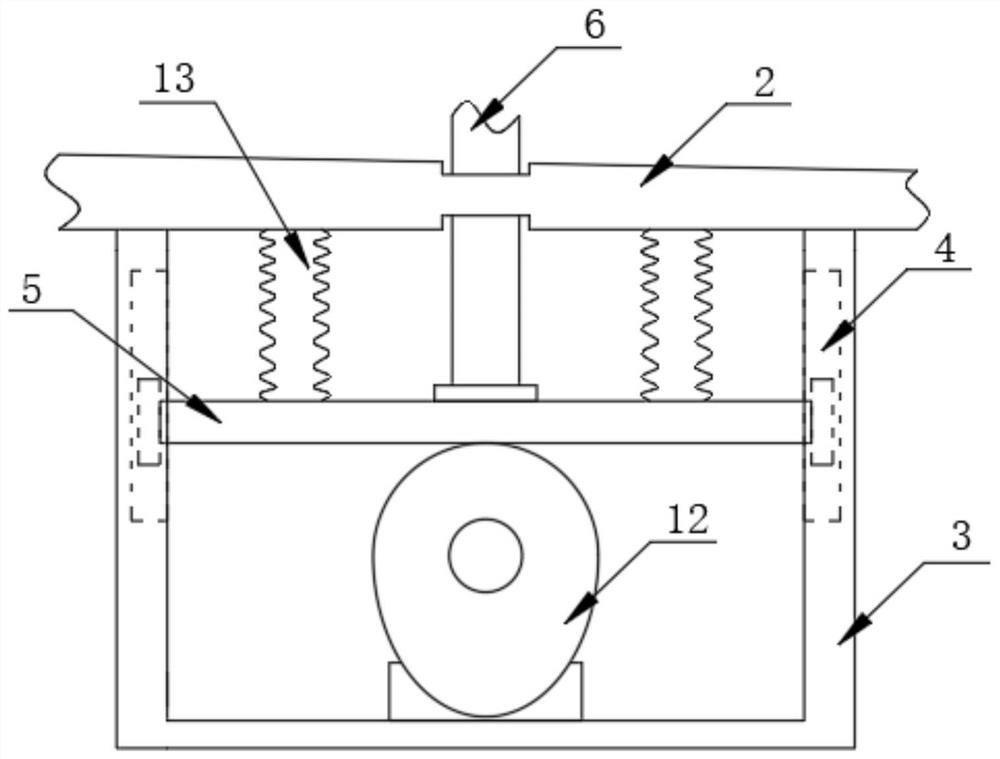

[0036]S1. Before purifying the sewage, the operator can input various parameter values of the water quality to the central processing unit 24 through the control button 25 as normal values during drainage, and the water quality detector 17 can detect various parameter values of the water quality during drainage as At the same time, the operator can configure the chemical neutralizer for sewage treatment in advance. The raw materials of the chemical neutralizer include: 20 parts of sodium metasilicate pentahydrate, 8 parts of aluminum oxide, 7 parts of sodium chloride, polypropylene 6 parts of amide, 8 parts of activated carbon, 12 parts of glycidyl polyquaternary amine, 3 parts of stabilizer, 16 parts of quicklime, 5 parts of gallic acid;

[0037] S2. When purifying the sewage, the operator can enter the sewage into the equipment box 1 through the water inlet hopper 28, and at the same time slowly add the chemical neutralizer through the liquid addition hopper 31, and at ...

Embodiment 2

[0042] S1. Before purifying the sewage, the operator can input various parameter values of the water quality to the central processing unit 24 through the control button 25 as normal values during drainage, and the water quality detector 17 can detect various parameter values of the water quality during drainage as At the same time, the operator can configure the chemical neutralizer for sewage treatment in advance. The chemical neutralizer raw materials include: 22 parts of sodium metasilicate pentahydrate, 10 parts of aluminum oxide, 11 parts of sodium chloride, polypropylene 7 parts of amide, 7 parts of activated carbon, 10 parts of glycidyl polyquaternary ammonium, 2 parts of stabilizer, 12 parts of quicklime, 4 parts of gallic acid;

[0043] S2. When purifying the sewage, the operator can enter the sewage into the equipment box 1 through the water inlet hopper 28, and at the same time slowly add the chemical neutralizer through the liquid addition hopper 31, and at t...

Embodiment 3

[0048] S1. Before purifying the sewage, the operator can input various parameter values of the water quality to the central processing unit 24 through the control button 25 as normal values during drainage, and the water quality detector 17 can detect various parameter values of the water quality during drainage as At the same time, the operator can configure the chemical neutralizer for sewage treatment in advance. The raw materials of the chemical neutralizer include: 25 parts of sodium metasilicate pentahydrate, 12 parts of aluminum oxide, 14 parts of sodium chloride, polypropylene 9 parts of amide, 5 parts of activated carbon, 8 parts of glycidyl polyquaternary amine, 1 part of stabilizer, 8 parts of quicklime, 3 parts of gallic acid;

[0049] S2. When purifying the sewage, the operator can enter the sewage into the equipment box 1 through the water inlet hopper 28, and at the same time slowly add the chemical neutralizer through the liquid addition hopper 31, and at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com