Method and device for cutting peripheral region of sheet

A peripheral area and cutting sheet technology, which is applied in the cutting of textile materials, textiles and papermaking, etc., can solve the problems of low production efficiency, time-consuming and laborious, etc., and achieve the goal of improving production efficiency, not easy to warp, and improving marking speed and accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

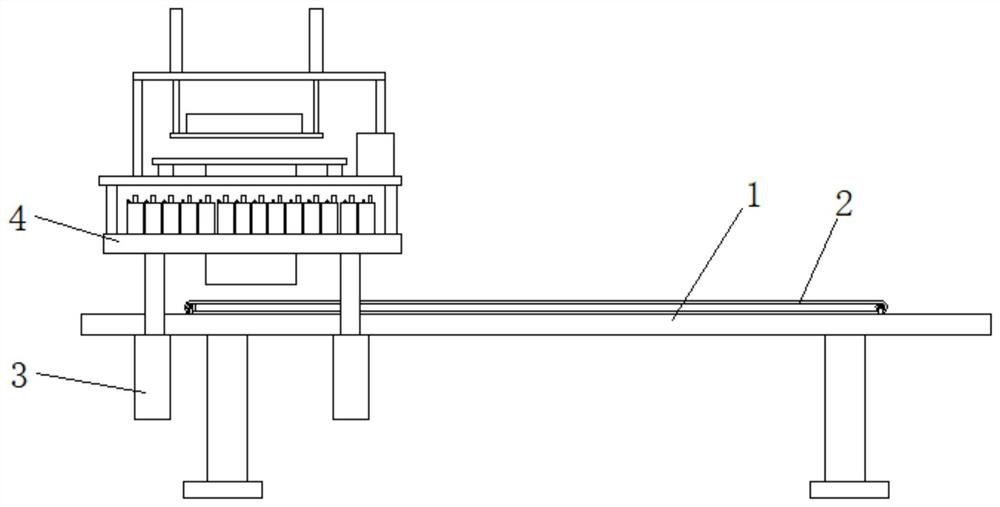

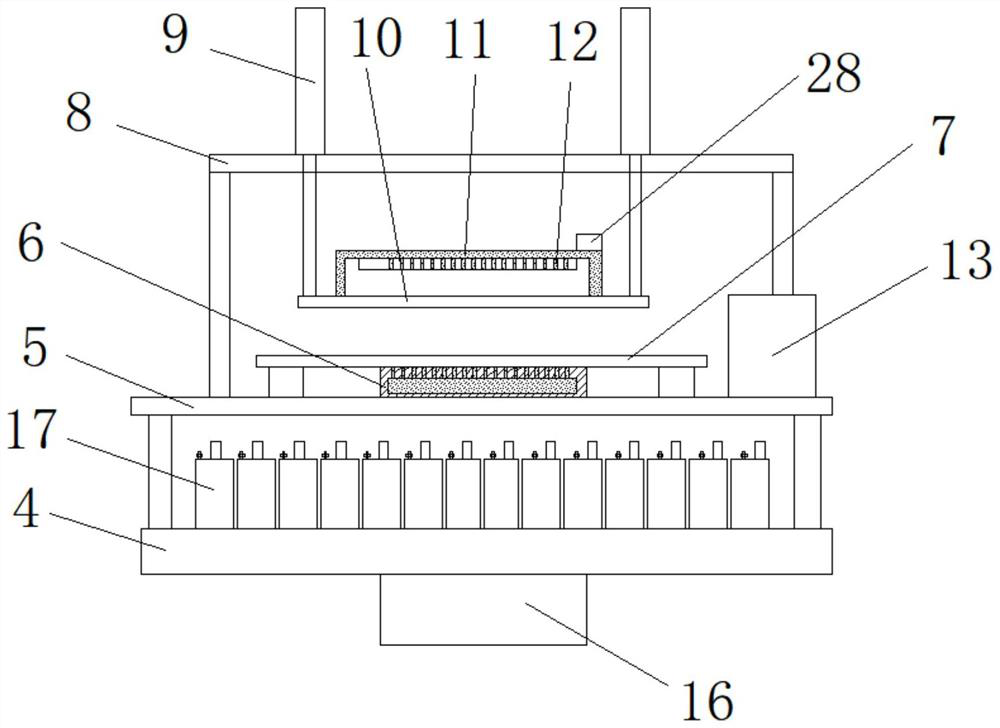

[0036] The present invention provides such Figure 1-6 A method of cutting a peripheral region of a sheet is shown, comprising the steps of:

[0037] S1. Sheet fixing: Lay the sheet on the top of the first transparent glass plate, and then start the second cylinder to drive the second transparent glass plate to press down the sheet, so that the first transparent glass plate and the second transparent glass plate are opposite to each other. The material is compressed;

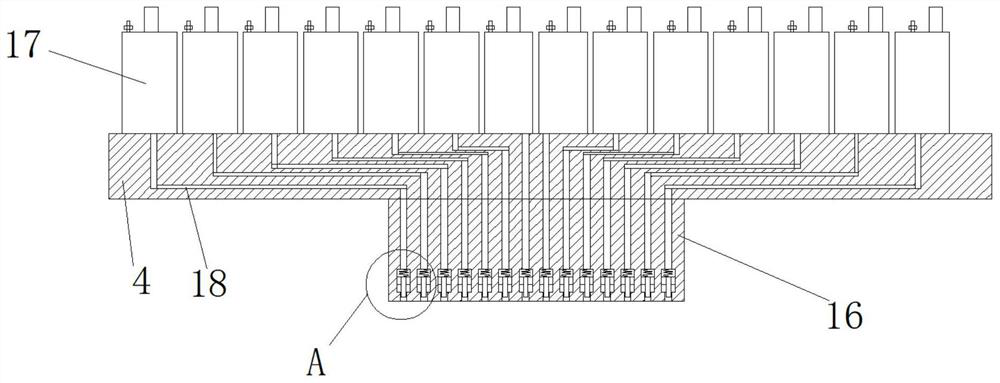

[0038] S2. Tiling and fixing the woven cloth: place the woven cloth on the conveyor belt after being flattened, and control the movable table through the first cylinder to drive the housing to move down to compress the woven cloth;

[0039] S3. Recognition of the sheet pattern: the laser light group irradiates the laser vertically downward, and the laser receiver arranged at the bottom of the first transparent glass plate receives the corresponding laser signal. The part blocked by the sheet cannot receive the ...

Embodiment 3

[0043] The present invention provides such Figure 1-6 A method of cutting a peripheral region of a sheet is shown, comprising the steps of:

[0044] S1. Sheet fixing: Lay the sheet on the top of the first transparent glass plate, and then start the second cylinder to drive the second transparent glass plate to press down the sheet, so that the first transparent glass plate and the second transparent glass plate are opposite to each other. The material is compressed;

[0045] S2. Tiling and fixing the woven cloth: place the woven cloth on the conveyor belt after being flattened, and control the movable table through the first cylinder to drive the housing to move down to compress the woven cloth;

[0046] S3. Recognition of the sheet pattern: the laser light group irradiates the laser vertically downward, and the laser receiver arranged at the bottom of the first transparent glass plate receives the corresponding laser signal. The part blocked by the sheet cannot receive the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com