Treating agent for manufacturing soft tissues and preparation method of treating agent

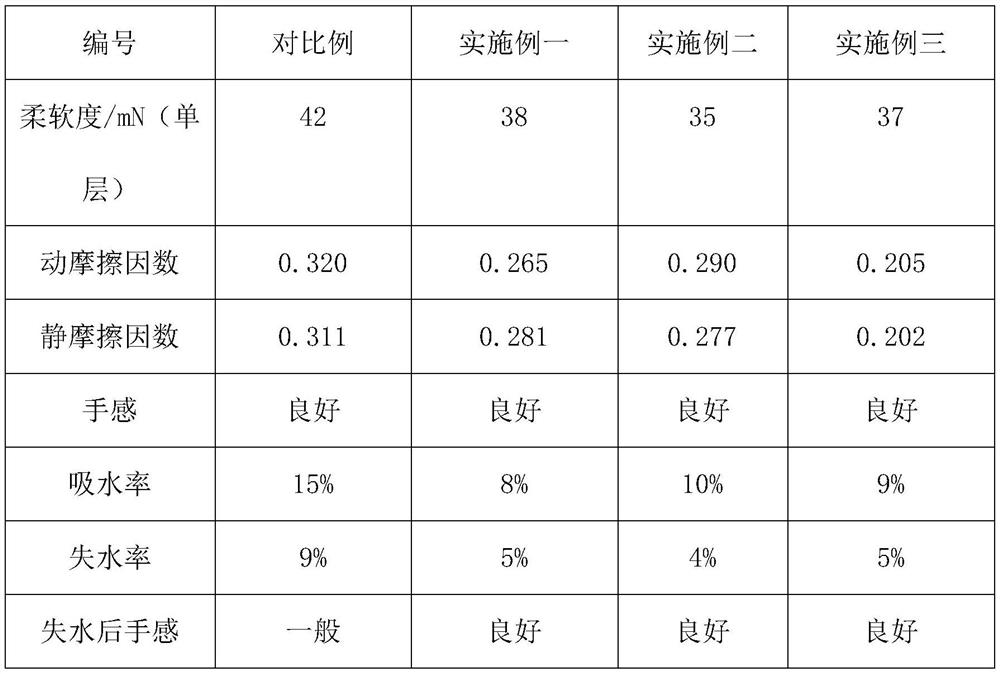

A treatment agent and paper towel technology, used in papermaking, textiles and papermaking, fiber raw material processing, etc., can solve the problems of wet paper towels, deteriorating paper feel, easy to break, etc., and achieve good hydrophilicity, excellent softness and smoothness. sense of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] A preparation method for a treatment agent for making soft paper towels, applied to the above-mentioned treatment agent for making soft paper towels, characterized in that it comprises the following steps:

[0039] Step S1: Mix the quaternary ammonium salt, alkyl phosphate ester or alkyl polyoxyethylene ether phosphate ester with monoglyceride, raise the temperature to 60-100°C, and gradually add it under high-speed stirring with a high-speed disperser water to obtain a transparent or translucent emulsion;

[0040] Step S2: lower the temperature to 50-60°C, and add glycerin therein under stirring;

[0041] Step S3: adding a surplus of water therein;

[0042] Step S4: adjusting the pH of the treatment to be between 3 and 8 with sodium hydroxide or potassium hydroxide or citric acid.

Embodiment 1

[0045] Mix 10g of glyceryl monostearate and 10g of dioctadecyltrimethylammonium chloride, raise the temperature to 80°C, start high-speed stirring of the high-speed dispersant, gradually add 80g of water to it, and continue stirring at high speed for 1 hour after adding water .

[0046] Cool down to 55°C, adjust the stirring speed to 60 rpm, add 750g of glycerin to it, stir well, then add 150g of water to it, adjust the pH of the treatment solution to 5.2, continue stirring for 0.5h, and then pack it.

Embodiment 2

[0048] Mix 15g of glyceryl monostearate and 50g of distearyl hydroxyethyl methyl ammonium methyl sulfate, raise the temperature to 70°C, start the high-speed dispersant and stir at high speed, gradually add 135g of water to it, and continue to high-speed after adding water Stir for 1h.

[0049] Cool down to 55°C, adjust the stirring speed to 60 rpm, add 700g of glycerin to it, stir well, then add 100g of water to it, adjust the pH of the treatment solution to 3.8, continue stirring for 0.5h, and then pack it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com